Sunflower seed husking and separating machine

A cleaning machine and sunflower seed technology, applied in the direction of shelling, solid separation, filtering, etc., can solve the problems of environmental pollution, increased labor intensity, difficult to break the shell, etc., achieve high efficiency, ensure integrity and cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

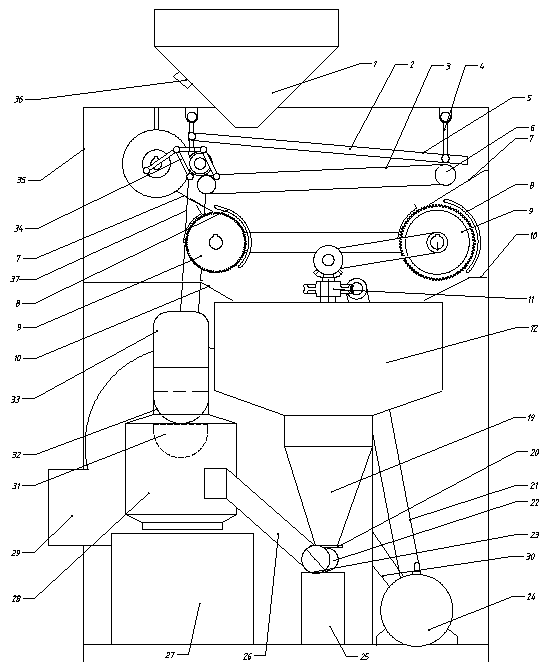

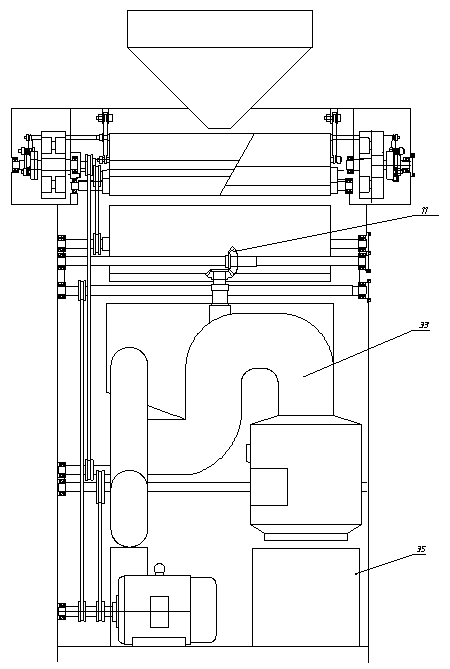

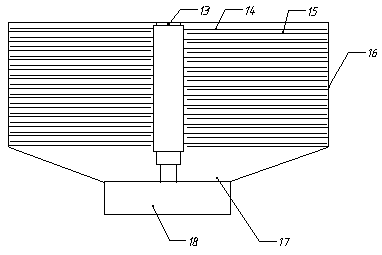

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 , 2 As shown, the sunflower seed peeling and cleaning machine of the present invention includes a frame 35, a feed screening device, a rolling and peeling device, a spiral rubbing and shelling device 12, a cyclone cleaning device, and a motor 24. The feed screening device includes a feed bin 1 , a vibrator 36 and a vibrating screen 2 . The vibrating screen 2 adopts the four-bar mechanism 34 to realize linear reciprocating vibration, and completes the two-stage shunting of sunflower seeds according to the size. Rolling and peeling drum 9, the small grains fall through the screen surface of vibrating screen 2 and fall on the conveyor belt 3 below, and then are transported to the left deflector 7 and enter the right rolling and peeling drum 9. The screen box 5 of the vibrating screen 2 is hoisted on the frame 35 by four booms 4 through bearings,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com