Dust measurement filter box opener and using method

A technology of opener and dust measurement, which is applied in the field of opener, can solve the problem of damage to the filter box, and achieve the effects of avoiding damage, convenient opening and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

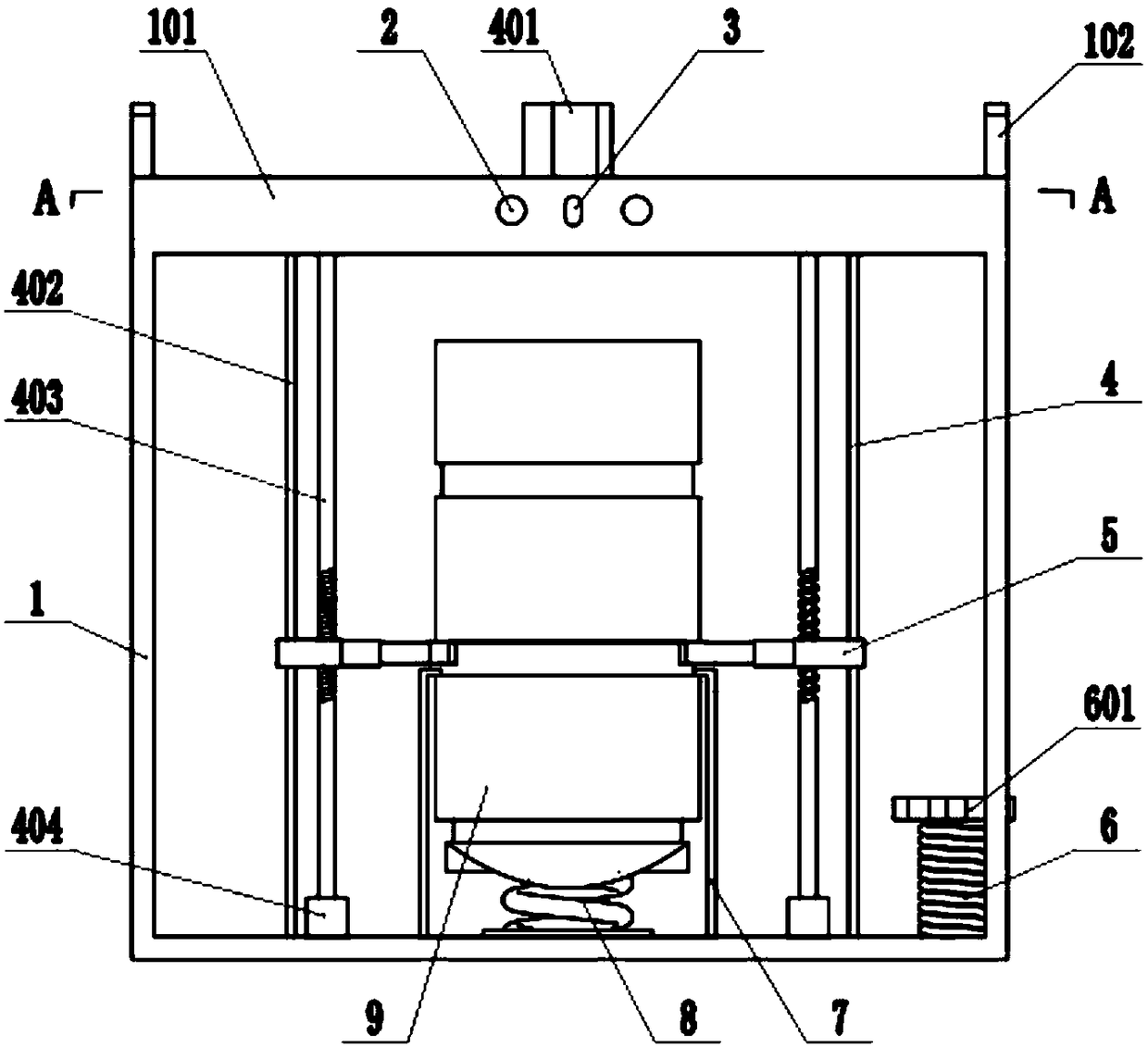

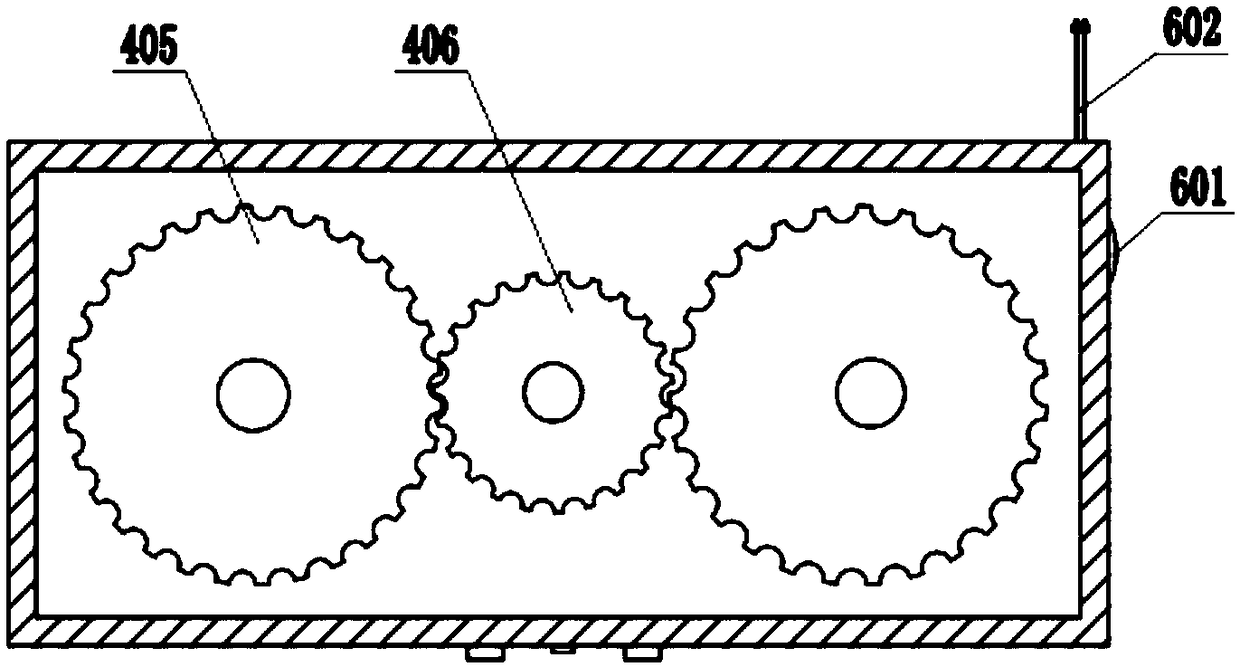

[0041] Such as Figure 1-3As shown, a dust measuring filter box opener includes a chassis 1, a transmission device 4, and a lifting device 5. The front side of the chassis 1 is an open structure, and the upper end of the chassis 1 is provided with a handle 102. The number of handles 102 is two Two, respectively located on both sides of the upper end of the cabinet 1, to facilitate the movement of the opener, a fixed seat 7 is provided in the middle of the bottom of the cabinet 1, and an extrusion device 8 is arranged in the fixed seat 7, and the extrusion device 8 and the cabinet 1 The lower side inner wall is connected, and the transmission device 4 includes a motor 401, a driving tooth 406, a driven tooth 405, a slide bar 402, and a threaded rod 403. In the middle of the upper inner wall of the chassis 1, a gear box 101 is arranged on the upper side of the interior of the chassis 1, the driving teeth 406 and the driven teeth 405 are all arranged in the gear box 101, the driv...

Embodiment 2

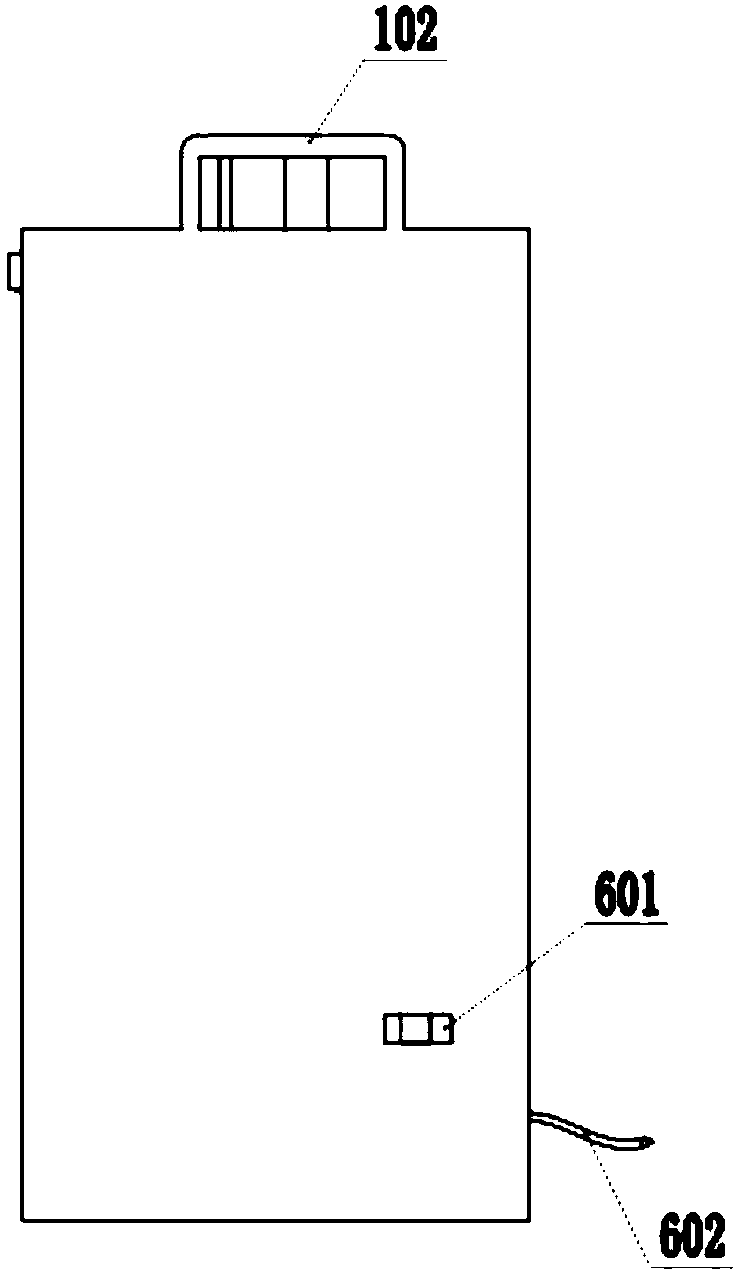

[0049] Such as Figure 8 As shown, the number of the sliding rod 402 and the threaded rod 403 is one, and the sliding rod 402 and the threaded rod 403 are arranged on the same side of the fixing seat 7, the number of the lifting device 5 is one, and the clamping plate 504 is a semicircle arc plate, and the middle part of the outer convex surface of the semicircle arc plate is connected with the telescopic rod 503. Because it is a semicircle arc plate, it can apply force to both sides of the filter box 9 at the same time, ensuring that the filter box 9 is evenly stressed. To ensure the normal opening of the filter box 9, the use of a lifting device 5 simplifies the operation steps and saves time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com