A lithium battery thermal management device

A lithium battery pack and thermal management technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of reducing the safety and reliability of electric vehicles, affecting the performance and service life of battery packs, and uneven temperature distribution of battery packs , to achieve the effect of easy promotion, simple structure and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

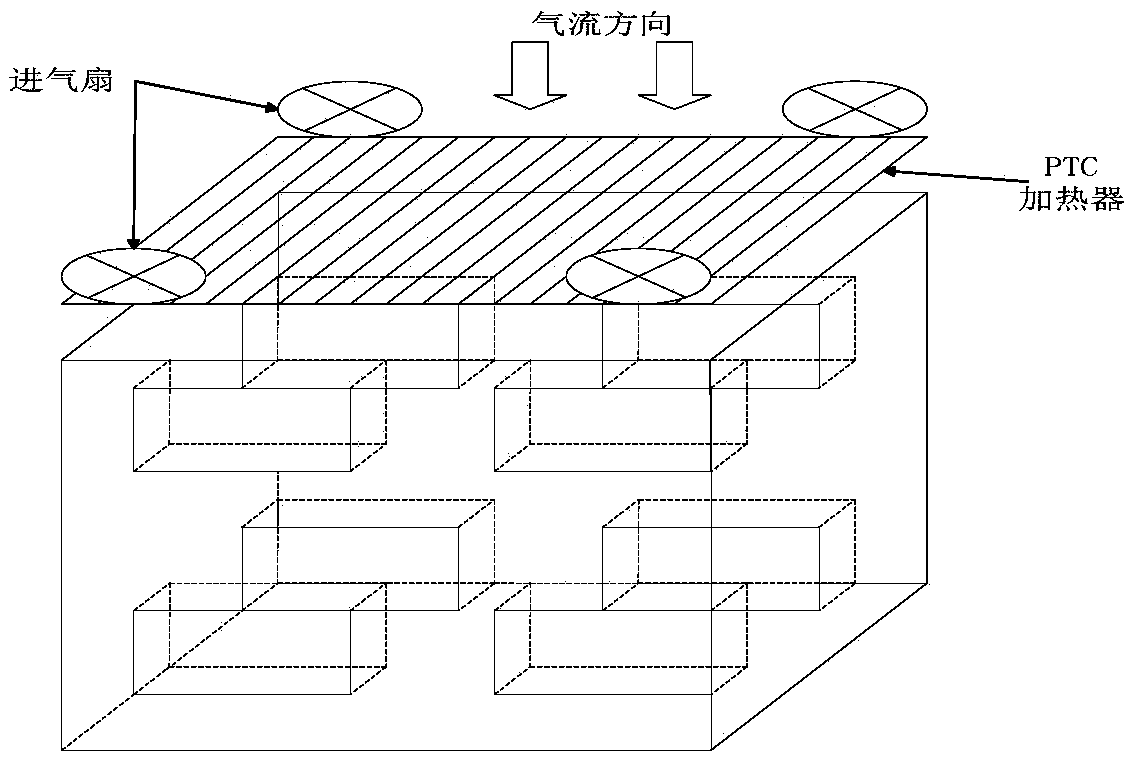

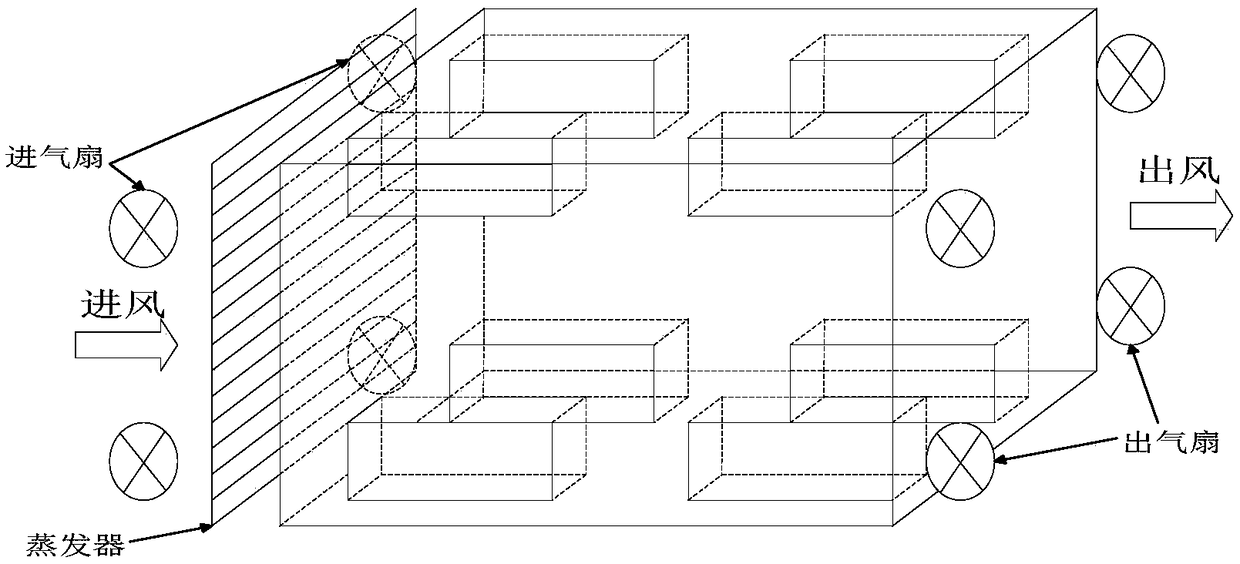

[0019] As shown in the figure, a thermal management device for a lithium battery pack includes a PTC heater, a heating intake fan, and a battery pack box. The battery pack box is provided with an air duct for air flow, and the battery pack box is provided with a hot air Air inlet, the heating air intake fan drives the hot air heated by the PTC heater into the battery box along the hot air inlet and flows along the air duct, so as to uniformly heat the battery modules in the battery box. The air duct in the battery box can be composed of the gaps between the battery cells, so that the hot air flowing along these gaps can heat each cell. The hot air inlet is arranged on the side wall of the battery case, the air intake fan is arranged beside the hot air inlet, and a PTC heater is arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com