Electric steamer condensate water back flow structure

A technology for condensing water and electric steaming furnace, applied in the field of electric steaming furnace, can solve the problems of insignificant condensation effect, waste of water resources, rapid water consumption of water tank, etc., so as to improve efficiency and use experience, improve heating efficiency, and prolong cooking time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

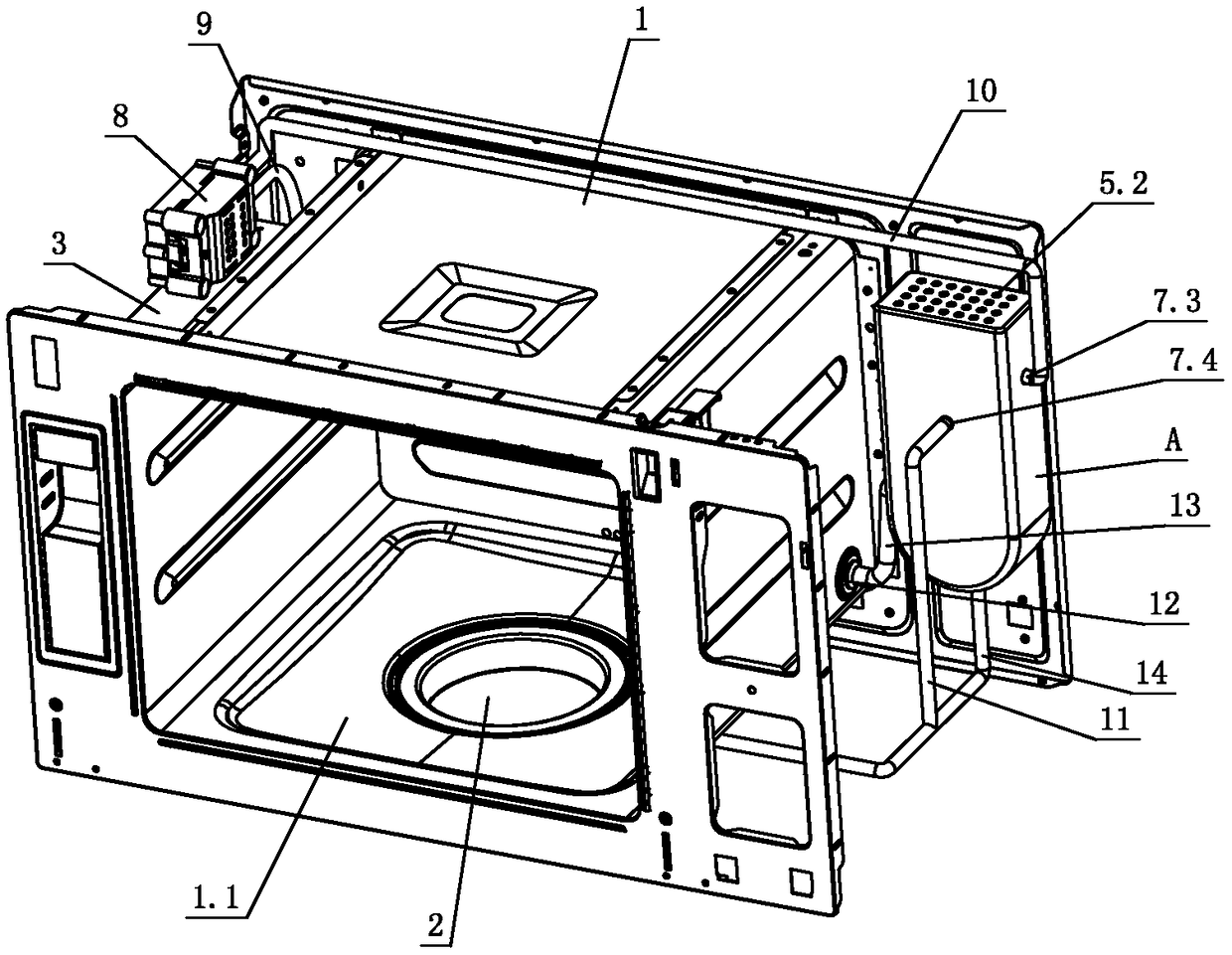

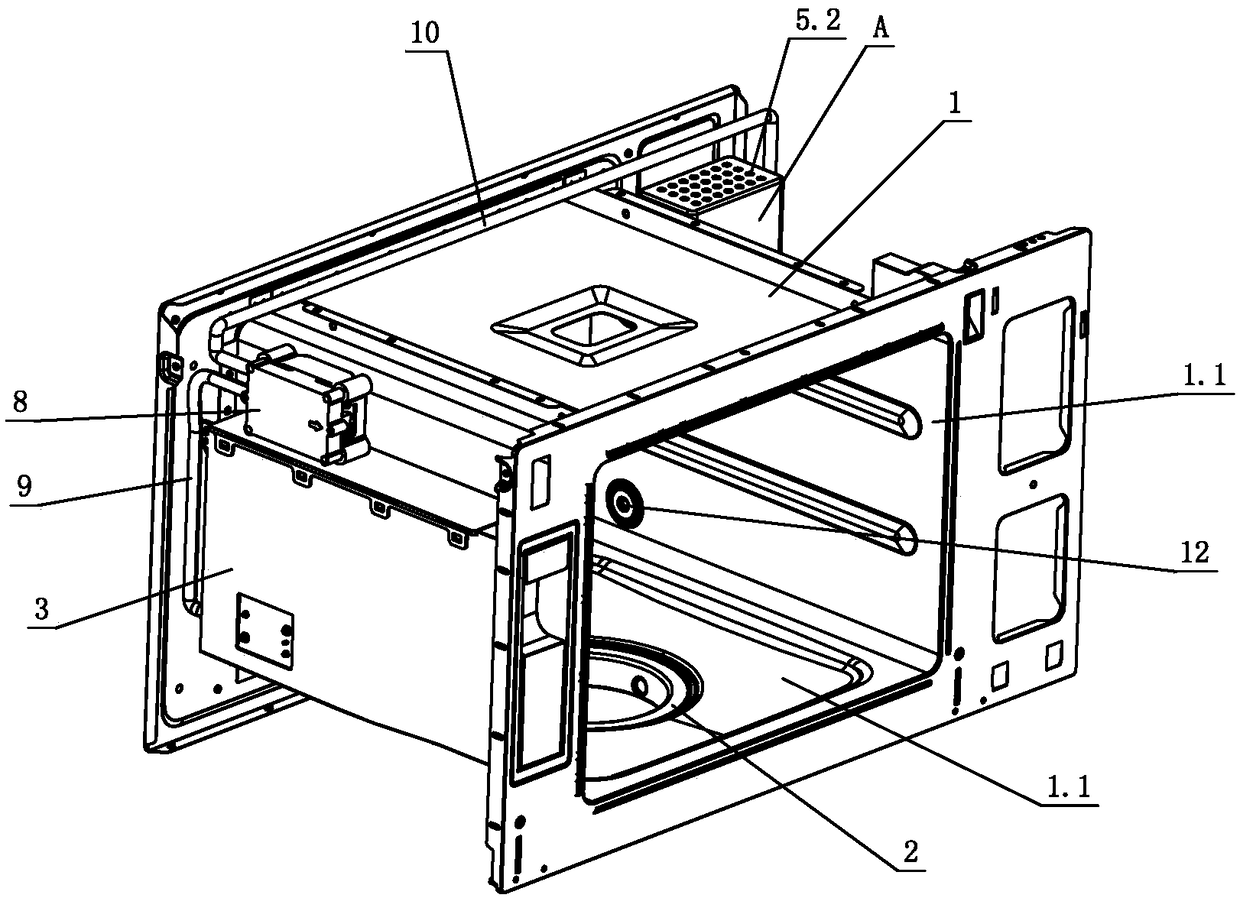

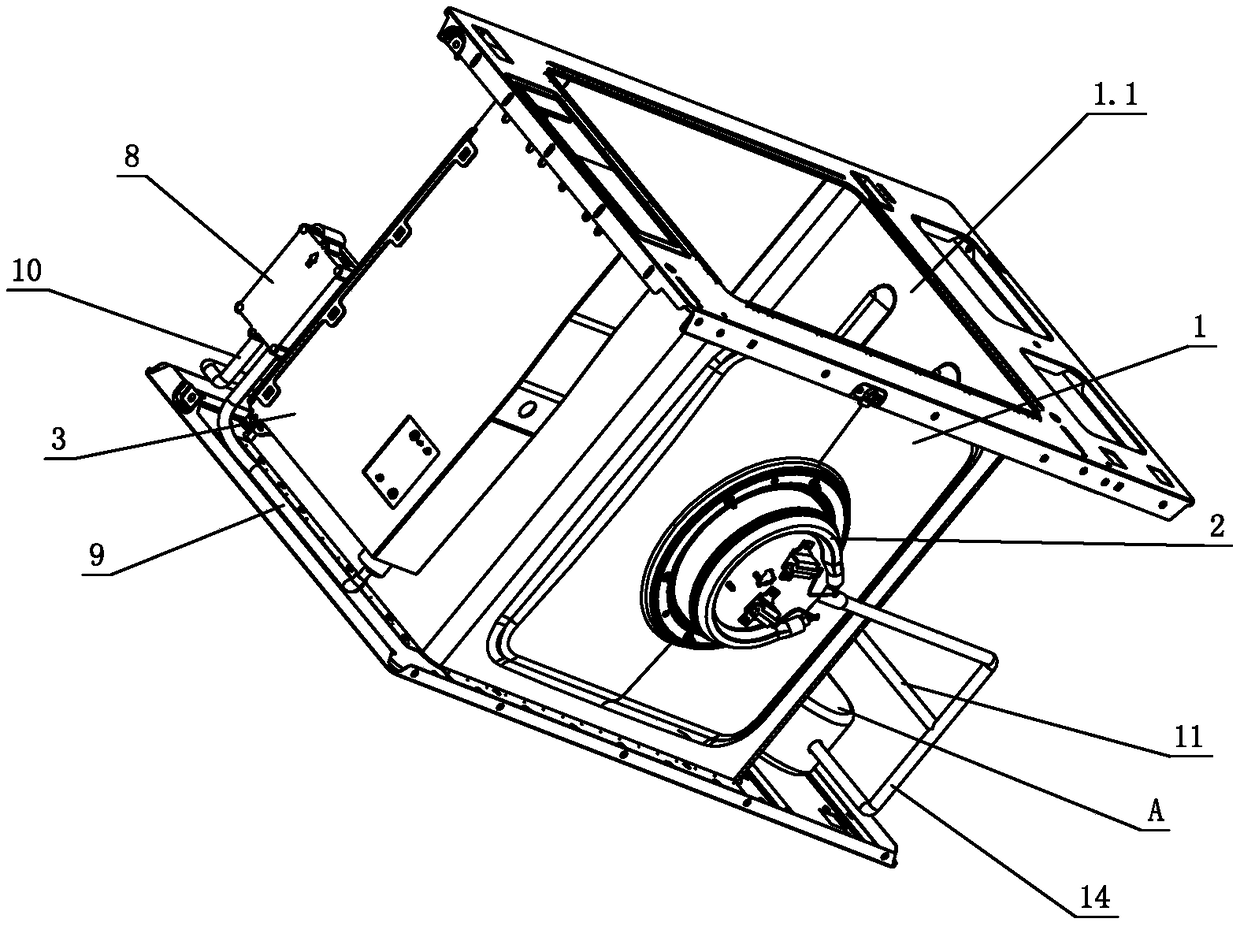

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0034] see Figure 1-Figure 15 , the condensed water return structure of this electric steamer includes an inner tank 1, a steam generator 2, a water tank 3 and a steam condensation box A. The inner cavity of the inner tank 1 is a steam cooking chamber 1.1, and the inner tank 1 is connected to the steam generator 2. The water tank 3 supplies water for the steam generator 2; the steam condensation box A is provided with an upper space A1, a middle space A2 and a lower space A3 from top to bottom; The middle exhaust holes 7.1 of the space A1 are connected to each other, and there are several (plural) bottom exhaust holes 7.2 connecting the lower space A3 between the middle space A2 and the lower space A3, and the middle exhaust holes 7.1 and the bottom exhaust holes 7.2 are one One corresponds, and the middle exhaust hole 7.1 and the bottom exhaust hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com