Method for manufacturing three-dimensional analysis tooth-preparation guide plate based on 3D printing and usage method thereof

A 3D printing and production method technology, applied in 3D printing, dentistry, dental prosthesis, etc., can solve the problems of poor correlation, complex production process, lack of analysis and consideration of restorations, etc., to achieve good tooth fit and improve effective The effect of resistance and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 provides a kind of three-way analysis based on 3D printing to prepare the tooth guide plate design, this method comprises the following steps:

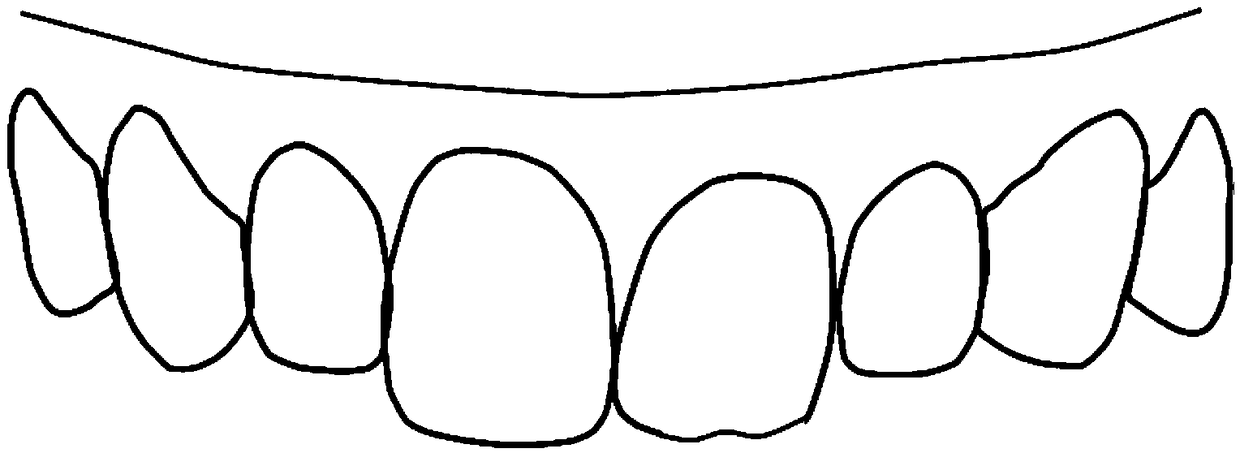

[0044] (1) Acquisition of digital models: By directly scanning the patient's mouth with an intraoral scanner, or scanning the patient's oral model / impression with a model scanner, a digital model of the oral condition is obtained, such as figure 1 Shown is the schematic diagram of the acquired digital model of the oral cavity.

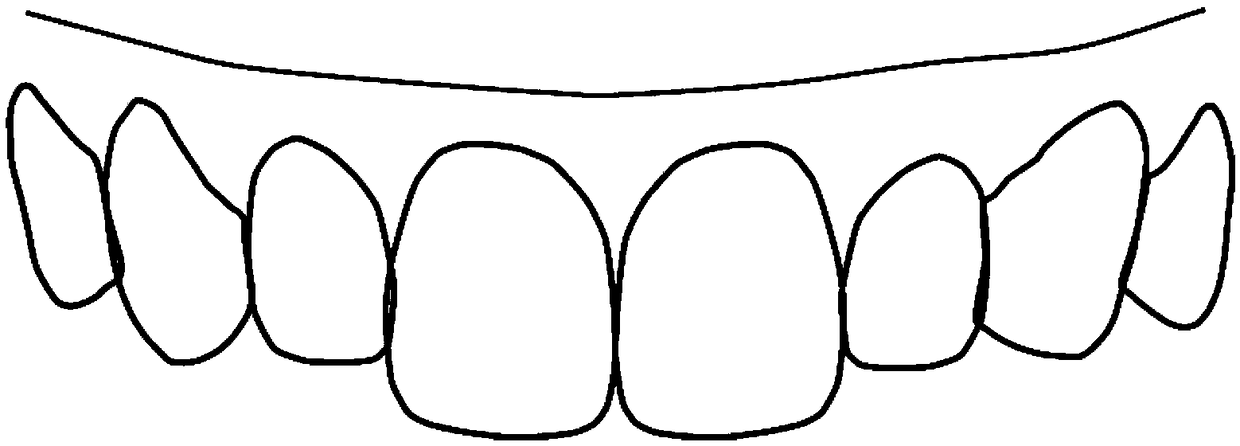

[0045] (2) Virtually design the target restoration: after importing the obtained oral digital model, refer to the state of adjacent teeth, homonymous teeth, and opposing teeth in the current oral model to personalize the design of the teeth to be restored, and use the designed Target restorations and models are exported separately. Wherein, the target restoration refers to the restored tooth.

[0046] (3) Virtual assembly model and target restoration: import the designed target restoratio...

Embodiment 2

[0062] This embodiment provides a method for using a 3D printed tooth preparation guide plate in actual restoration. The 3D printed tooth preparation guide plate is produced by any of the methods in the foregoing embodiments. The use method specifically includes the following steps:

[0063] Step A. Place the prepared tooth preparation guide plate on the teeth in the patient's mouth.

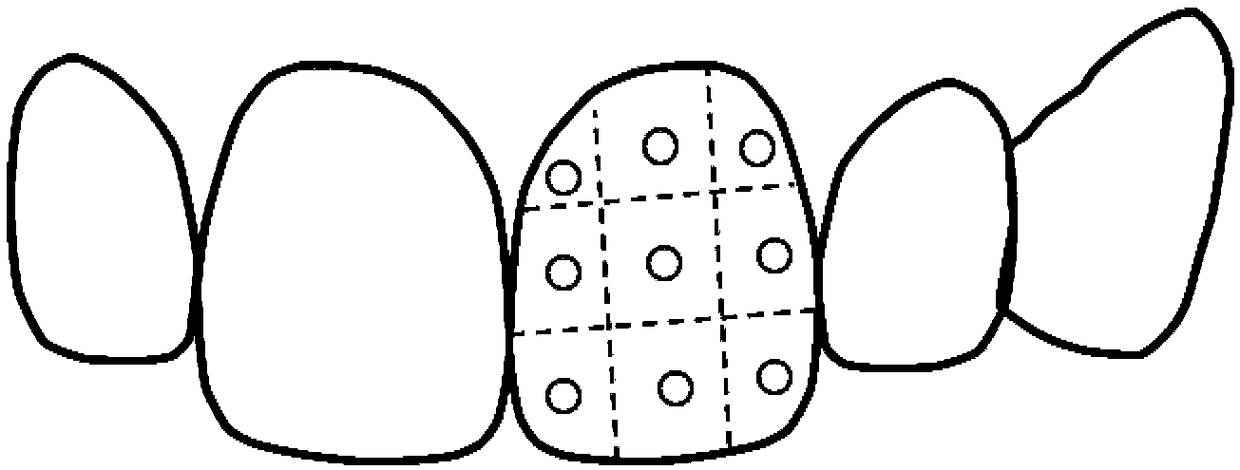

[0064] Step B. Measure the gap between the tooth surface at the fixed depth hole position and the surface of the prepared tooth guide plate with a fixed depth bur. If the measured gap is greater than or equal to the minimum thickness of the future restoration material, no tooth removal treatment will be performed here; If the gap is smaller than the minimum thickness of the future restoration material, the tooth here will be removed, and the amount of tooth removal is the difference between the minimum thickness of the future restoration material and the measured gap.

[0065] C. According to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com