Homogenizing machine for producing organic fertilizer

A technology for homogenizers and organic fertilizers, applied to mixers with rotating stirring devices, mixers, chemical instruments and methods, etc., can solve problems such as low work efficiency, inability to fully stir, and low quality of organic fertilizer homogenization. To achieve the effect of improving discharge efficiency and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

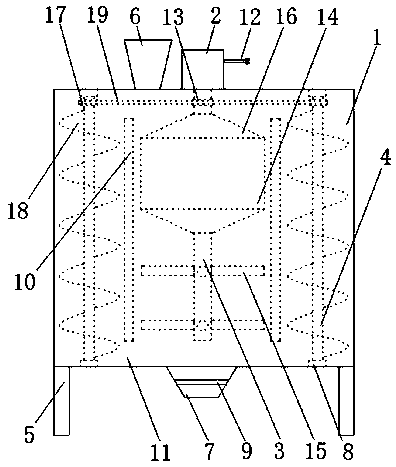

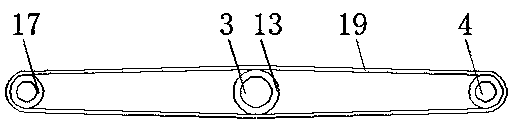

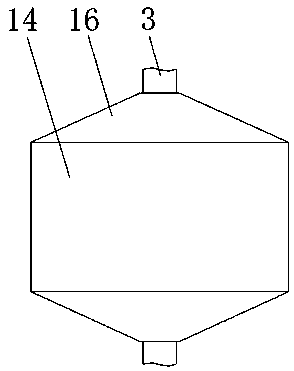

[0020] as attached Figure 1-3 As shown, a homogenizer for organic fertilizer production includes a homogenizer 1, a motor 2, a transmission shaft 3 and a driven shaft 4, and is characterized in that: the homogenizer 1 is arranged on a support 5, The top of the homogenization barrel 1 is provided with a feed bin 6 and the bottom is provided with a discharge bin 7, and bearings 8 are arranged on the top and bottom of the homogenization barrel 1, the motor 2 is arranged on the top of the homogenization barrel 1, and A power cord 12 is provided on the motor 2, and one end of the transmission shaft 3 is connected to the motor 2, and the other end is arranged in the homogenizing barrel 1, and the drive shaft 3 is sequentially provided with a driving wheel 13, a grinding Roller 14, stirring rod 15, described driven shaft 4 two ends are arranged in the bearing 8 of homogenizing tank 1 inner top, inner bottom respectively, and driven wheel 17 is arranged on driven shaft 4 top, and dri...

Embodiment 2

[0028] as attached Figure 4 Shown: as attached Figure 1-3 As shown, a homogenizer for organic fertilizer production includes a homogenizer 1, a motor 2, a transmission shaft 3 and a driven shaft 4, and is characterized in that: the homogenizer 1 is arranged on a support 5, The top of the homogenization barrel 1 is provided with a feed bin 6 and the bottom is provided with a discharge bin 7, and bearings 8 are arranged on the top and bottom of the homogenization barrel 1, the motor 2 is arranged on the top of the homogenization barrel 1, and A power cord 12 is provided on the motor 2, and one end of the transmission shaft 3 is connected to the motor 2, and the other end is arranged in the homogenizing barrel 1, and the drive shaft 3 is sequentially provided with a driving wheel 13, a grinding Roller 14, stirring rod 15, described driven shaft 4 two ends are arranged in the bearing 8 of homogenizing tank 1 inner top, inner bottom respectively, and driven wheel 17 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com