A stirring device for biopharmaceuticals

A mixing equipment and biopharmaceutical technology, which is applied in chemical/physical processes, mixers, dissolution, etc., can solve the problems of incompatible drugs and low mixing efficiency, so as to increase the mixing efficiency of drugs, improve the mixing effect, and improve The effect of mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

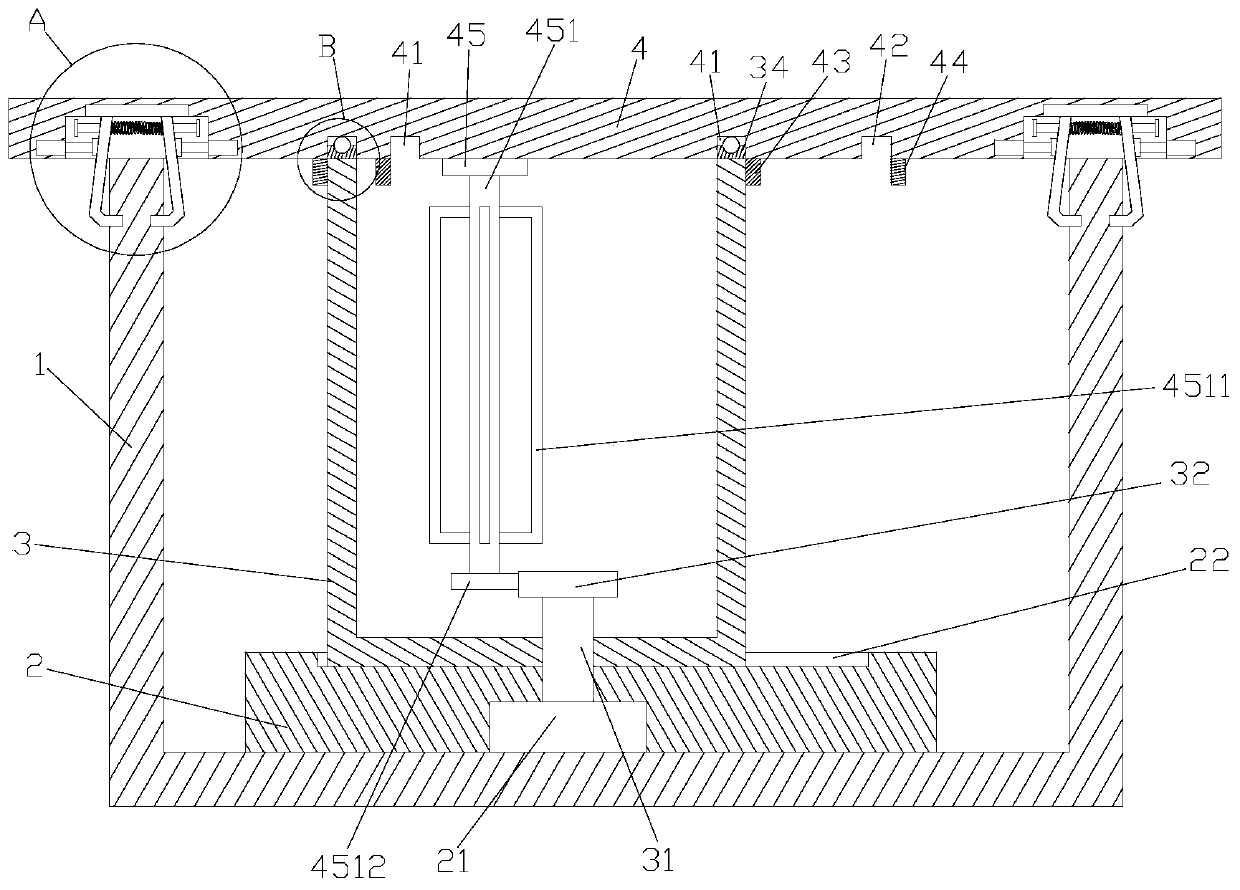

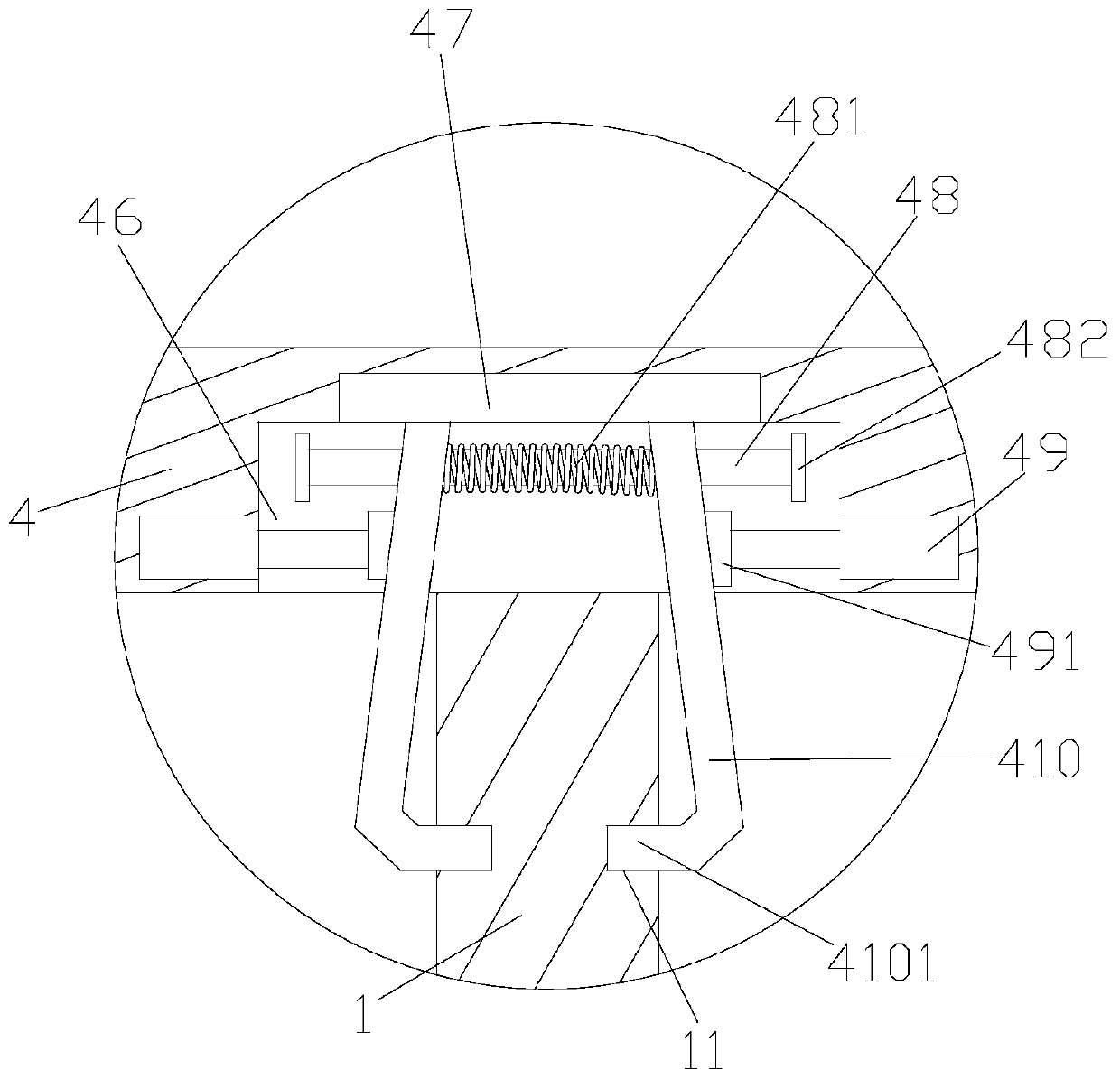

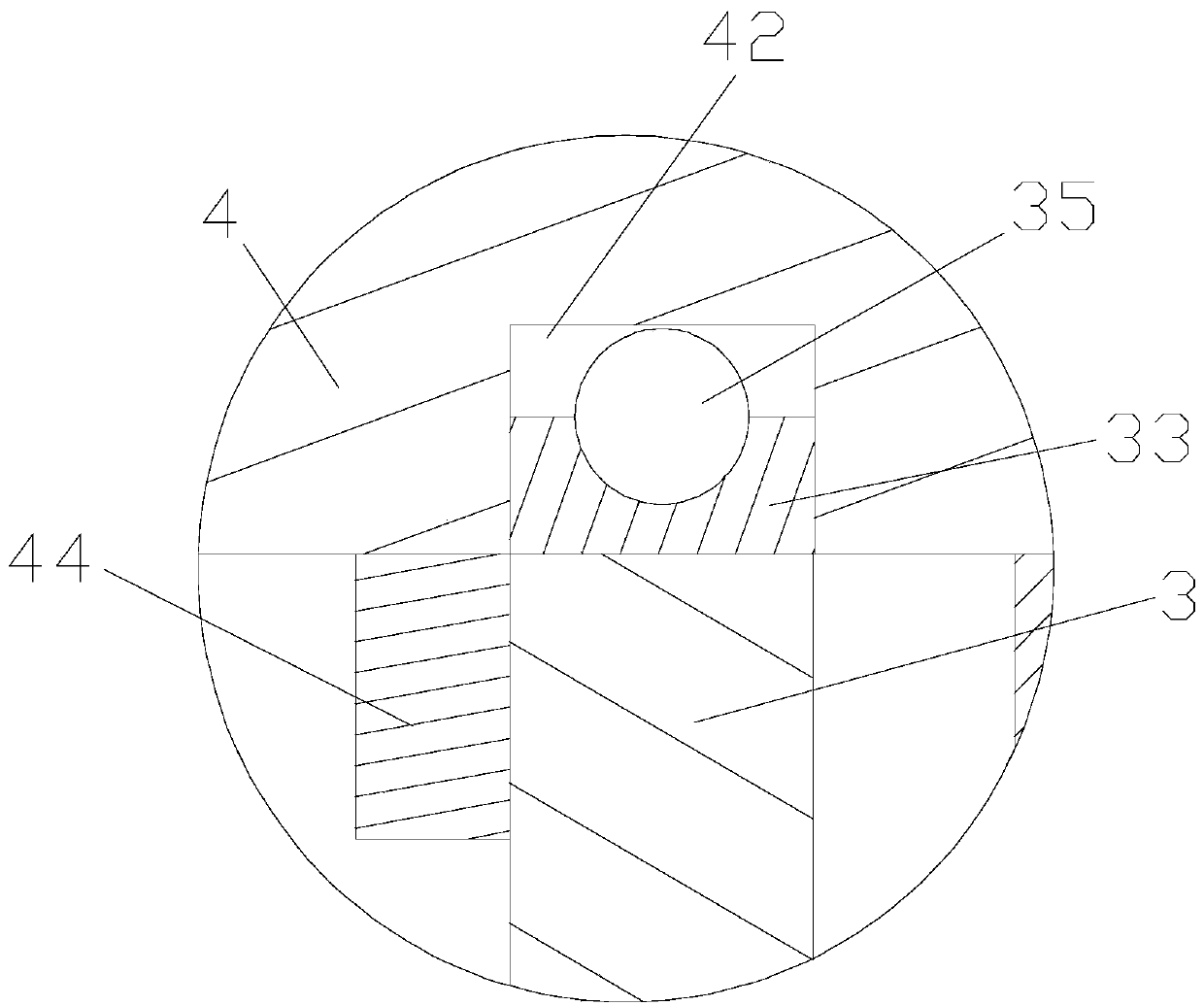

[0032] Such as Figure 1-7 Shown, a kind of mixing equipment for biopharmaceuticals comprises an outer box body 1, a support seat 2 located at the bottom of the outer box body 1, an inner box body 3 located on the support seat 2 and an inner box body located at the outer box body 1. The box cover 4 on the box body 1, the support seat 2 is a rectangular structure, fixedly connected to the bottom of the outer box body 1, the support seat 2 is a platform made of metal material, and the box cover 4 acts as a seal for the outer box body 1 and the inner box body 3 , to prevent the medicine from being thrown out of the box when stirring in the box, reducing the loss of medicine; the bottom surface of the box cover 4 is provided with a bearing 45, and the bearing 45 is provided with a stirring shaft 451, and the stirring shaft 451 is provided with Four stirring rods 4511, the stirring rods 4511 are symmetrically arranged, the stirring shaft 451 can rotate under the connection of the b...

Embodiment 2

[0043] Such as Figure 8-10 As shown, the difference between this embodiment and Embodiment 1 is: the bearing 45 is provided with a connecting sleeve 452, the stirring shaft 451 is detachably connected to the connecting sleeve 452; the connecting sleeve 452 is fixedly connected to the bearing 45 The stirring shaft 451 is connected on the bearing 45 through the connecting sleeve 452, so that the stirring shaft 451 can rotate under the effect of the bearing 45, so that the stirring shaft 451 drives the stirring rod 4511 to rotate and stir the medicine in the casing; through the connecting sleeve 452 is detachably connected to the stirring shaft 451. After the stirring equipment has stirred the primary medicine, the stirring shaft 451 can be easily removed from the connecting sleeve 452, which is convenient for cleaning the stirring shaft 451 and the stirring rod 4511, avoiding the The primary medicine remains on the stirring shaft 451, and when the stirring shaft 451 stirs the n...

Embodiment 3

[0050] Such as Figure 11-14 As shown, the difference between this embodiment and Embodiment 1 is that: the inner wall of the inner box body 3 is provided with a water pushing plate 37, and the inner wall of the outer box body 1 is provided with a control assembly for controlling the movement of the water pushing plate 37; When the inner box body 3 rotated under the effect of the rotating motor 21, the water pushing plate 37 indirectly played the role of pushing medicine under the action of the control assembly on the inner wall of the outer box body 1; through the water pushing plate 37 and the inner box body 3 cooperate with each other, so that the inner box body 3 is blocked by the water pushing plate 3 when driving the medicine to rotate, and it acts as a barrier to the medicine in rotation, causing the medicine to collide inside it after a sudden stop, increasing the internal collision of the medicine chance, thereby increasing the number of times the medicines come into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com