Novel chemical production equipment

A technology for chemical production and equipment, applied in the field of new chemical production equipment, can solve problems such as equipment life shortening, enterprise safety accidents, and enterprise economic losses, and achieve the effects of good maintenance, good sealing performance, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

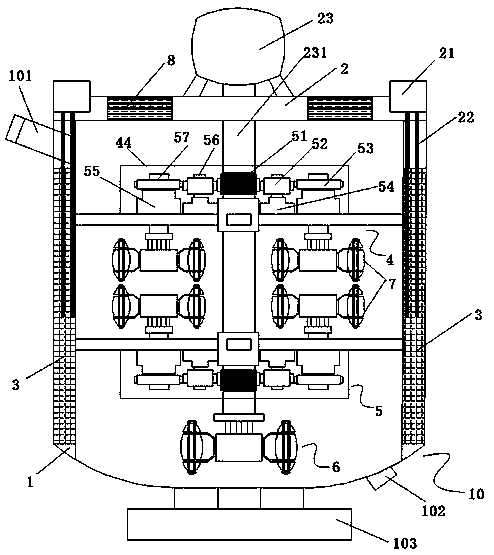

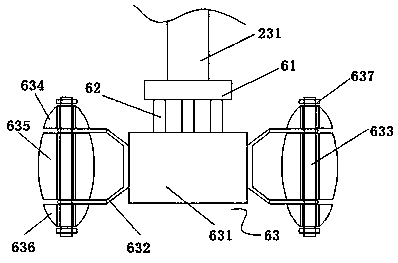

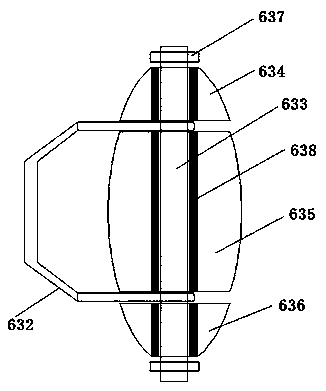

[0038] A new type of chemical production equipment, comprising a reaction tank 10, the reaction tank is provided with an interlayer 1, a cover 2 is arranged above the reaction tank, and the upper part of the interlayer is an opening structure, and it is characterized in that the interlayer is provided with The polymer hydrogel layer 3, the two ends of the cover body are symmetrically provided with a condensation chamber 21, and the capillary column 22 is symmetrically connected below the condensation chamber, and the capillary column is connected with the polymer hydrogel layer; the reaction tank A fixed frame 4 is arranged in inner symmetry, a transmission assembly 5 is arranged on the fixed frame, a driving device 23 is arranged on the cover plate, the driving device is connected with a rotating shaft 231, and the rotating shaft passes through the fixed frame , the rotating shaft is connected to the transmission assembly; the first stirring assembly 6 is connected below the r...

Embodiment 2

[0062] This embodiment provides a new type of chemical production equipment with the same structure as in Embodiment 1. The difference is that the polymer hydrogel layer includes the following components in parts by weight: 2 parts of acrylic acid, 11 parts of N-ethyl Acrylamide, 4 parts of ethylene oxide, 0.8 parts of maleic anhydride, 0.7 parts of potassium persulfate, 0.2 parts of 2,2-dimethylol propionic acid, 0.03 parts of calcium zinc stabilizer and 75 parts of pure water, 36 parts ethanol.

[0063] The preparation method of the polymer hydrogel layer in this example is as follows: Dissolve N-ethylacrylamide and acrylic acid in pure water, then add potassium persulfate, fill with nitrogen, raise the temperature to 38°C, and preheat for 15 minutes Add maleic anhydride, stir and react for 10 hours, then add ethanol and hexane oxide to dissolve completely, add 2,2-dimethylol propionic acid, calcium zinc stabilizer and continue stirring for 3 hours, add and pour into the mol...

Embodiment 3

[0065] This embodiment provides a new type of chemical production equipment with the same structure as in Embodiment 1, except that the polymer hydrogel layer includes the following components in parts by weight: 5 parts of acrylic acid, 17 parts of N-ethyl Acrylamide, 8 parts of ethylene oxide, 2 parts of maleic anhydride, 1.5 parts of potassium persulfate, 0.6 parts of 2,2-dimethylol propionic acid, 0.05 parts of calcium zinc stabilizer and 85 parts of pure water, 48 parts ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com