A hydraulic control shearing process of a shearing machine

A shearing machine and hydraulic technology, which is applied in the field of hydraulic systems, can solve the problems of affecting the service life of the shearing machine and the blade, the impact of the shearing machine and the blade, and the poor performance of the machine tool, so as to achieve large oil flow and improve Quality, the effect of small motor power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

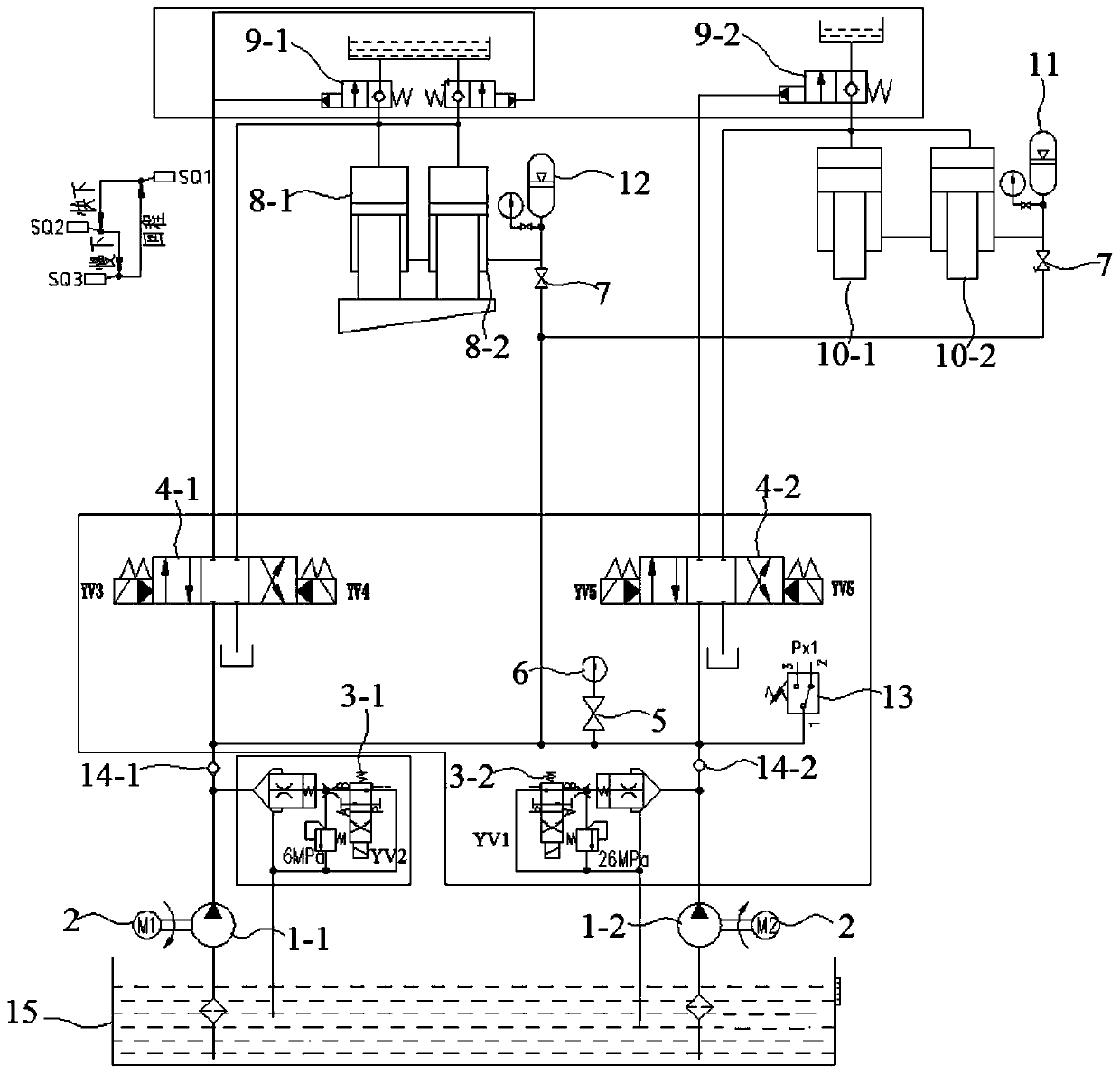

Embodiment 1

[0045] In view of the deficiencies of the existing hydraulic system of the shearing machine, this embodiment optimizes the structure of the hydraulic system, abandons the disadvantages of the traditional hydraulic system of the shearing machine, and realizes the independent action of the pressing cylinder. Utilizing the cooperation of the high and low pressure oil pump motor unit, and controlling the hydraulic valve through electrical appliances, on the one hand, the simultaneous or sequential return of the shearing cylinder and the pressing cylinder can be realized, which increases the action performance of the machine tool and greatly improves the work efficiency; on the other hand The combined oil supply of double pumps is used to supply oil to the shearing cylinder for rapid downward movement, and then through YV2 power failure, the single-pump oil supply is used for slow-speed high-pressure downward shearing, that is, through the reasonable switching of two sets of high and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com