Detachable concrete lintel mold

A concrete, disassembled technology, applied in the direction of molds, etc., can solve the problems of material loss, waste of manpower and material resources, and inability to adjust the lintel at the construction site, and achieve the effects of good adaptability, easy production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate the understanding of the present invention, the following description will be given in conjunction with the drawings and embodiments.

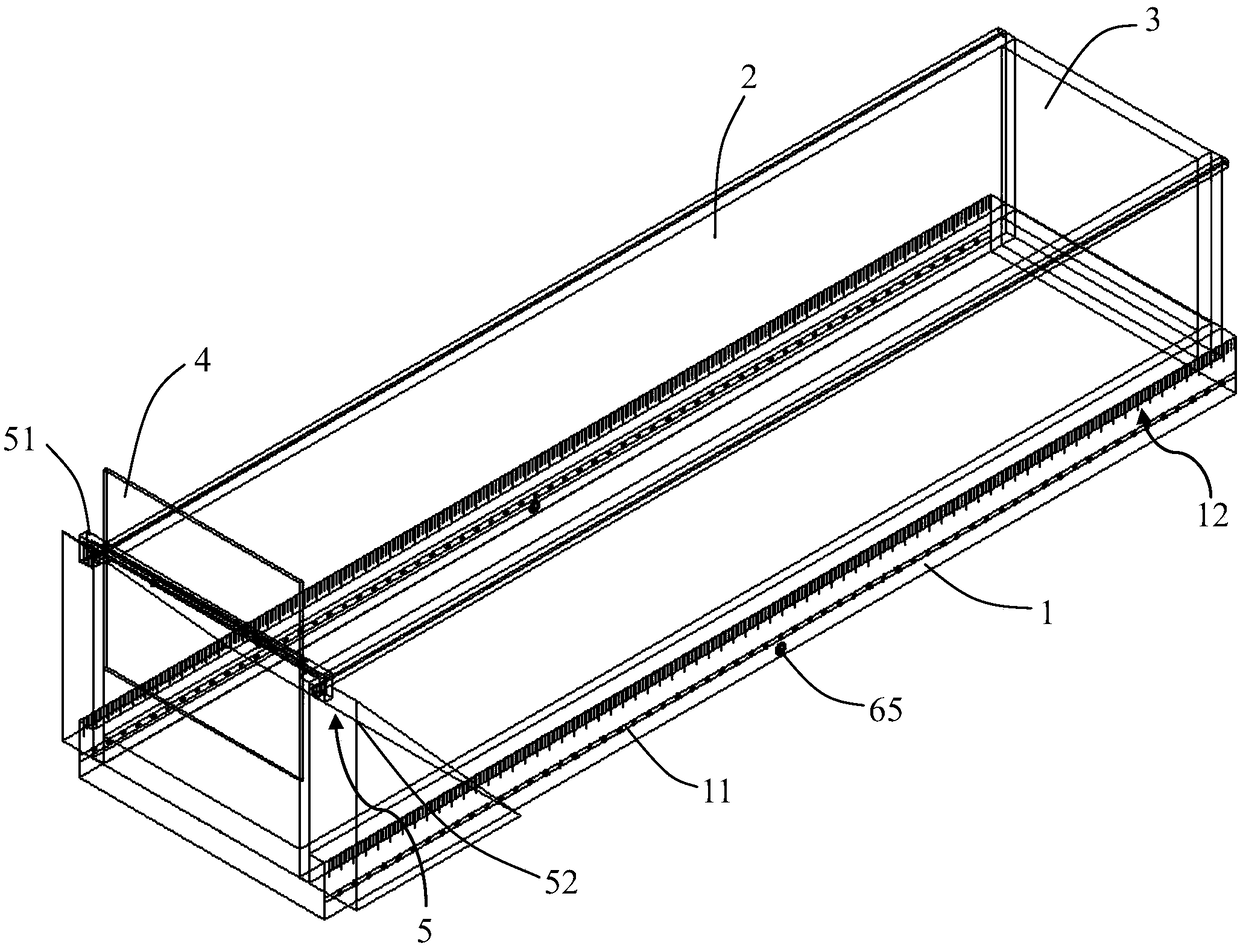

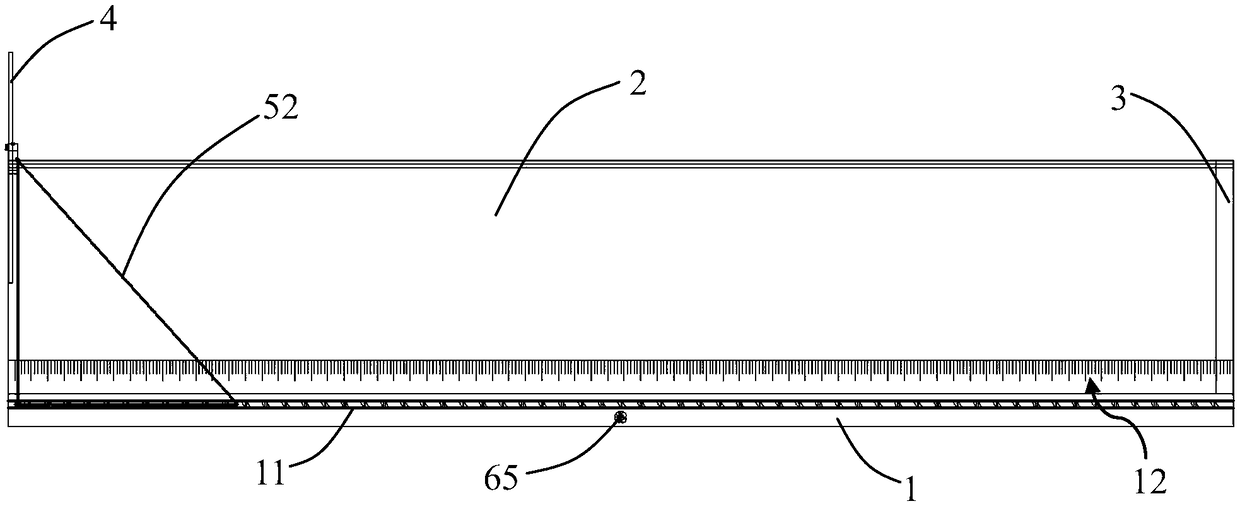

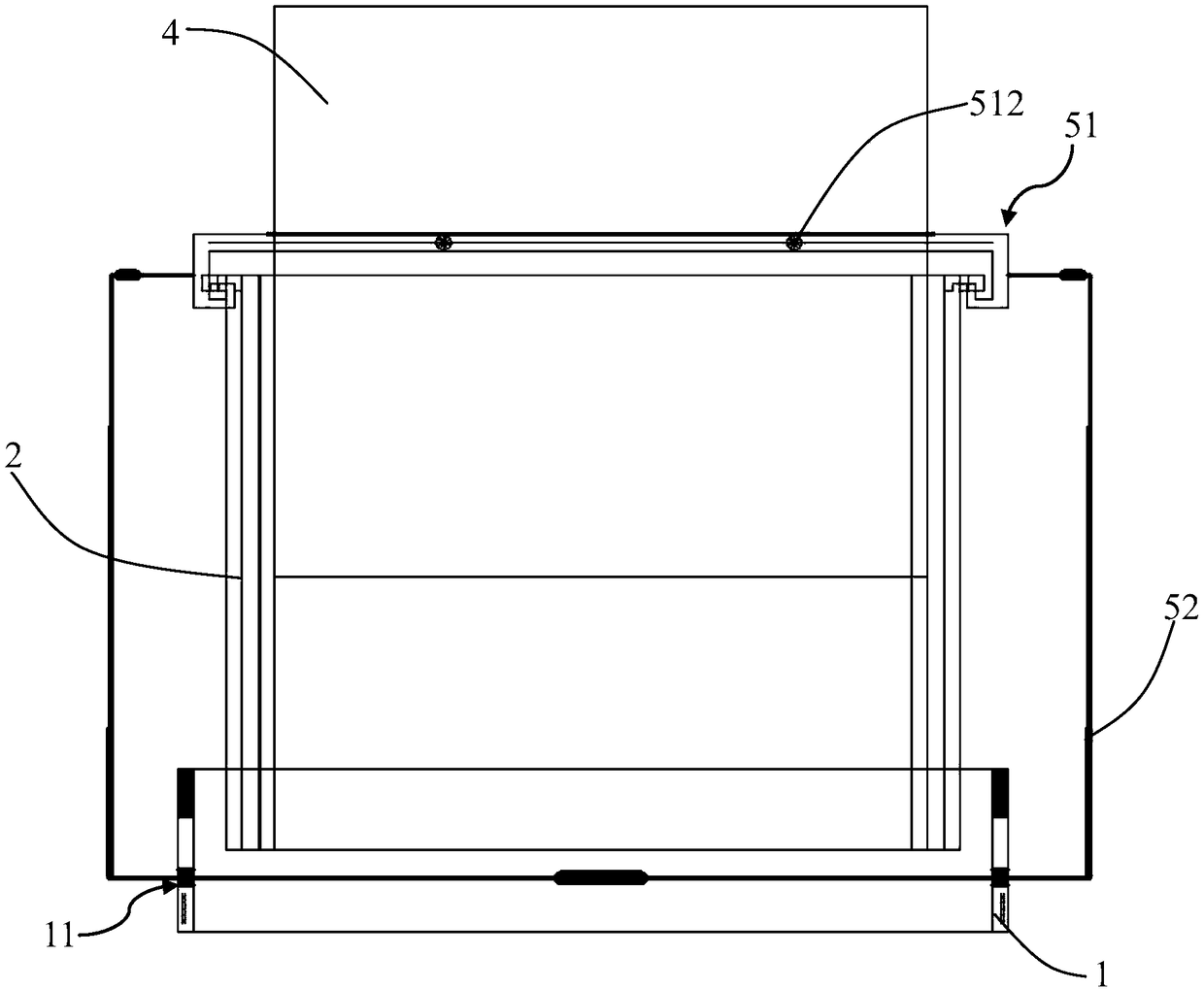

[0030] See Figure 1 to Figure 5 with Figure 7 It can be seen that the present invention discloses a detachable concrete lintel mold, including: bottom mold 1, side mold 2, first baffle 3, second baffle 4 and movable frame 5; specifically, the bottom mold 1 A first chute 11 is provided on opposite sides respectively. The two side molds 2 are relatively detachably mounted on the bottom mold 1 and correspond to the two first chutes 11 one by one. The bottom mold 1 and the two side plates 2 are surrounded to form two ends And the concrete pouring space with the top opening, the two sides of the first baffle 3 are detachably connected to the two side molds 2 and are used to seal the first end opening of the concrete pouring space, and the two sides of the second baffle 4 are attached to the two sides The inner wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com