Demolding mechanism and method

A technology of demolding mechanism and demoulding device, applied in ceramic molding machines, auxiliary molding equipment, unloading devices, etc., can solve the problems of brick wear, incomplete demoulding, sticking, etc., to avoid wear and ensure integrity , Improve the effect of separation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

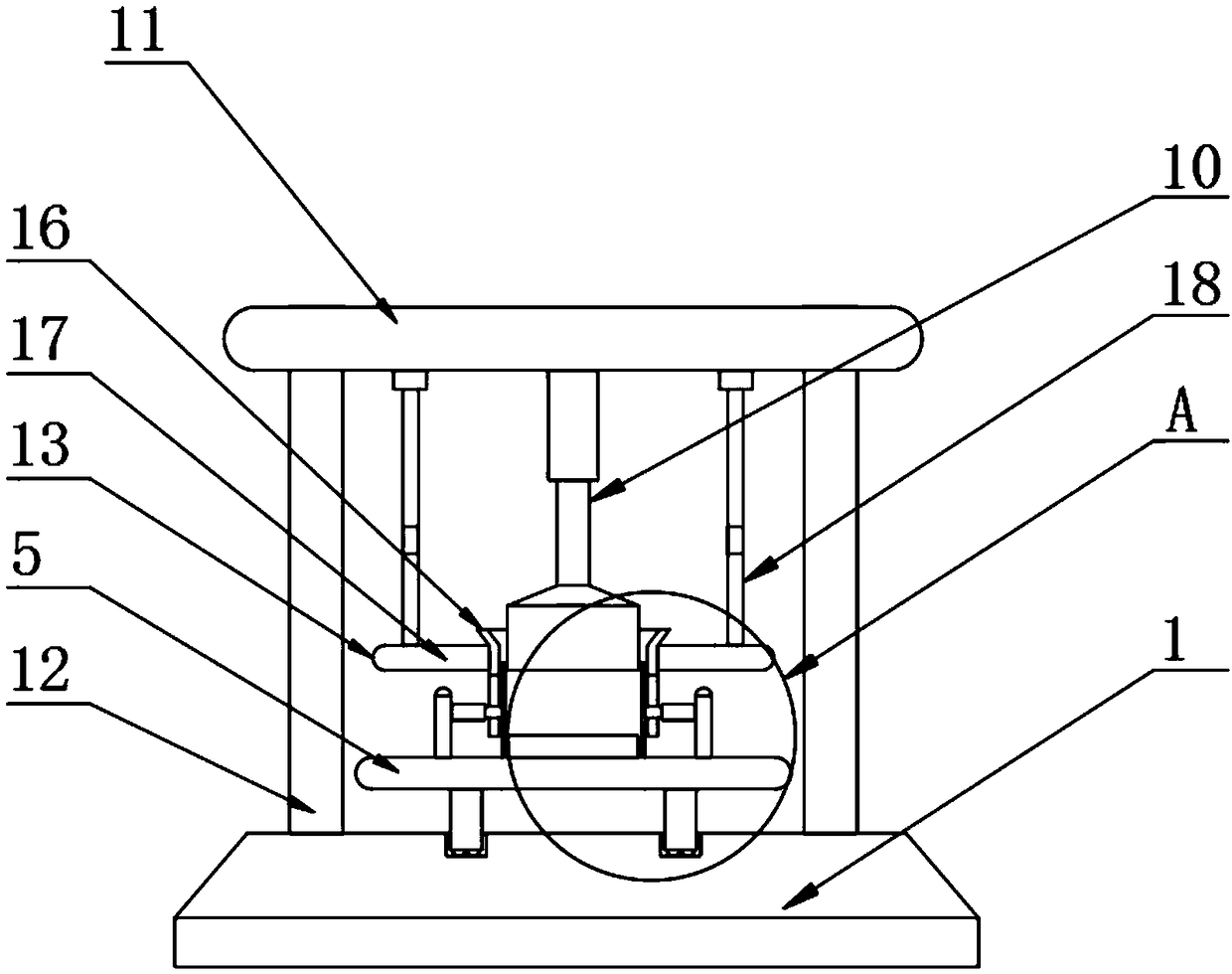

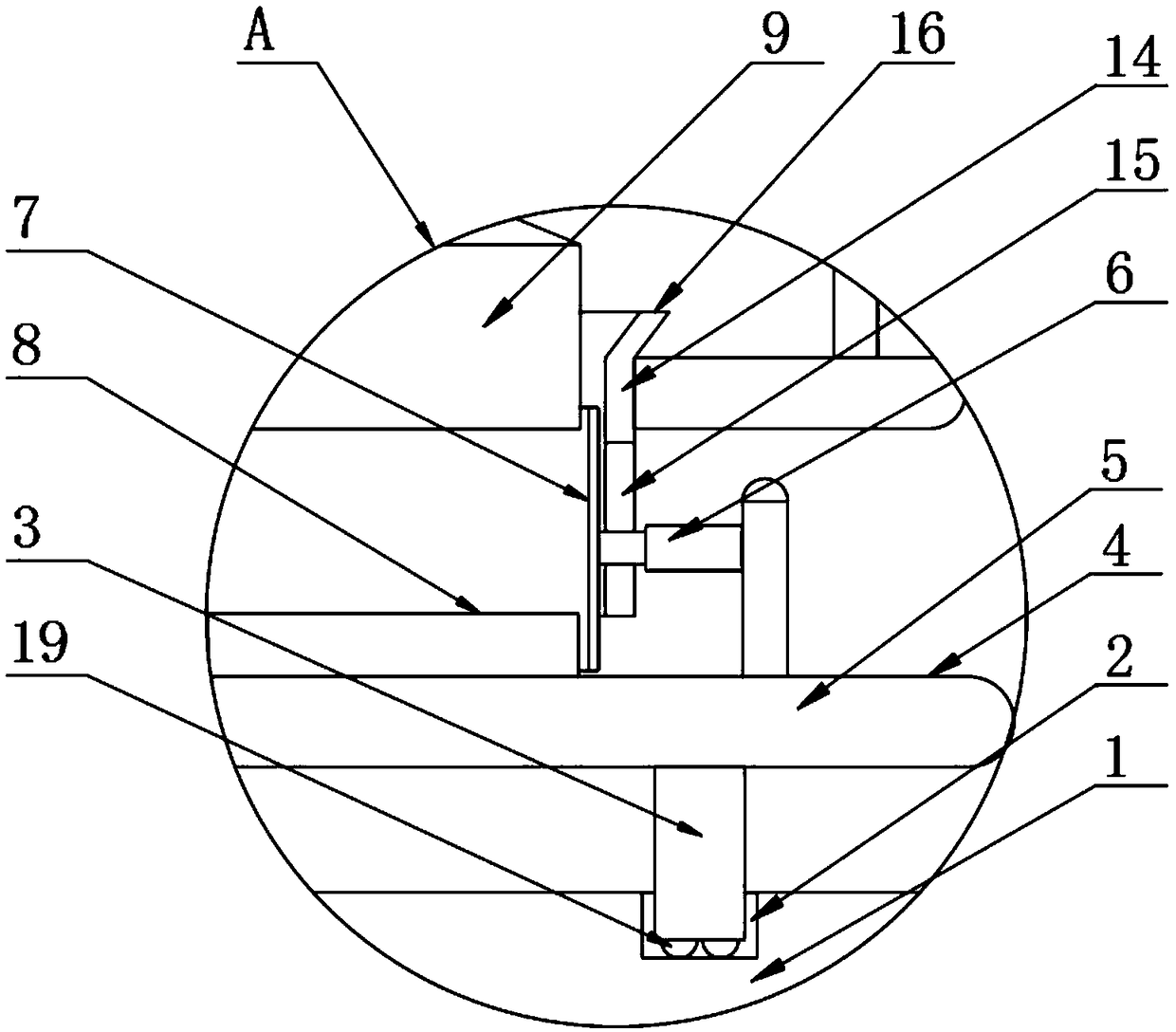

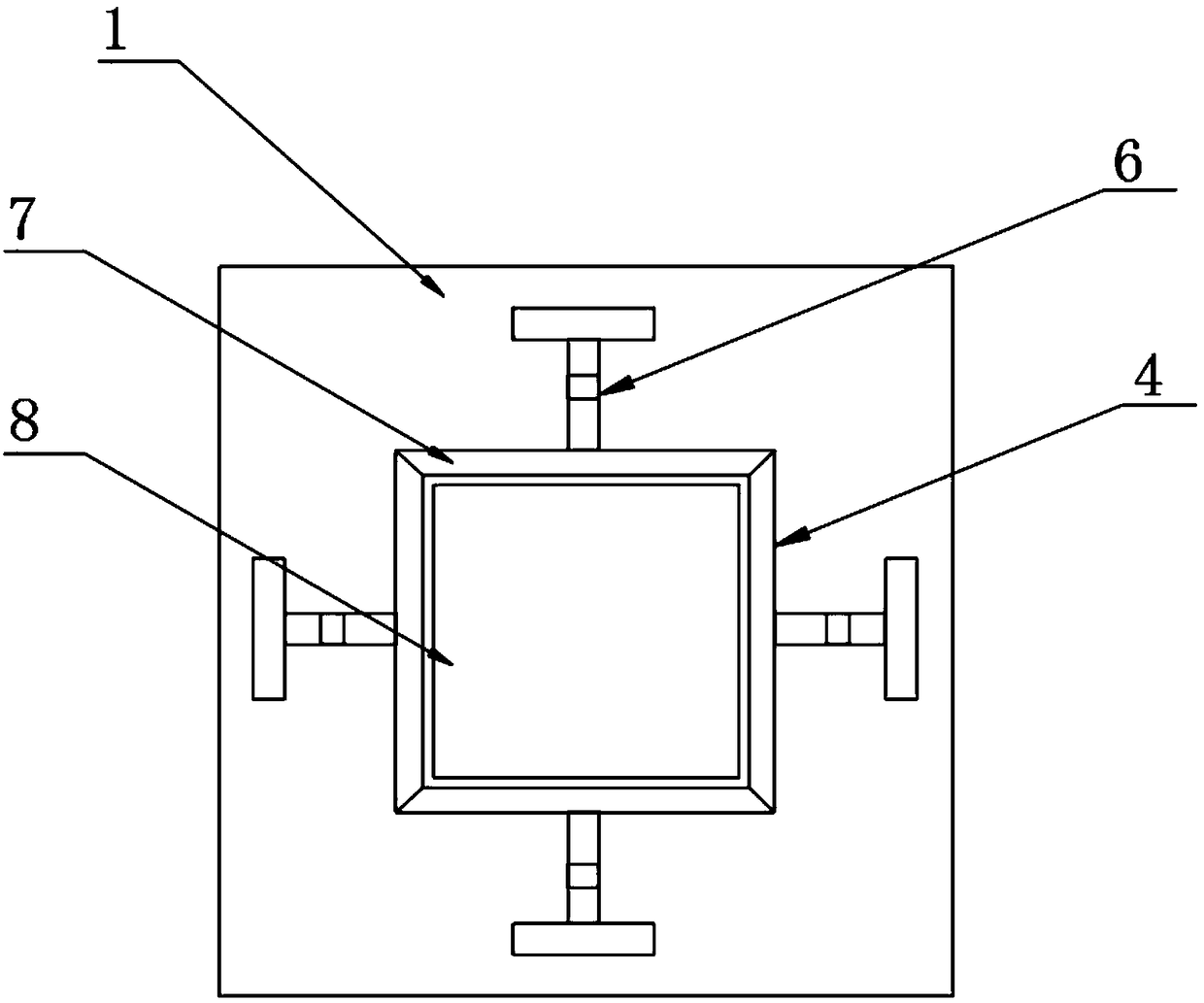

[0024] The present invention provides such as Figure 1-3 A demoulding mechanism shown includes a base 1, the surface of the base 1 is provided with a chute 2, the inside of the chute 2 is provided with a slider 3, and the slider 3 is slidably connected with the chute 2, the The top of the slider 3 is provided with a demoulding device 4, including a fixed plate 5, the top of the fixed plate 5 is provided with a vertical plate, one side of the vertical plate is provided with a first hydraulic rod 6, and one side of the first hydraulic rod 6 is A shaping plate 7 is provided, and a pressure table 8 is arranged on one side of the shaping plate 7, and the output shaft of the first hydraulic rod 6 is fixedly connected with the shaping plate 7, and a pressure block 9 is arranged on the top of the shaping plate 7, and the pressure block 9 is arranged on the top of the shaping plate 7. The top of the block 9 is provided with a second hydraulic rod 10, the output shaft of the second hyd...

Embodiment 2

[0034] A demoulding method, comprising said demoulding mechanism, also includes the following steps:

[0035] S1: The brick material enters into the mold cavity surrounded by four shaping plates 7;

[0036] S2: Open the second hydraulic rod 10 and the electric telescopic rod 18, the second hydraulic rod 10 pushes the briquetting block 9 to squeeze the brick material, and at the same time, the electric telescopic rod 18 drives the material guide cylinder 14 to rise;

[0037] S3: Then open the first hydraulic rod 6, the first hydraulic rod 6 drives the four shaping plates 7 to separate horizontally from the brick embryo, and the pressing table 8 makes the brick embryo at a higher position, which is used to move the brick embryo, and at the same time passes through the slider 3. The fixed plate 5 is moved, and the brick embryo is completely separated and demoulded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com