Device for manufacturing bicolor co-extruded plastic-wood floor

A technology of co-extrusion and wood flooring, applied in applications, household components, household appliances, etc., can solve the problems of large glue pollution, high production costs, and excess colors, and achieve control of production and use costs, high production efficiency, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

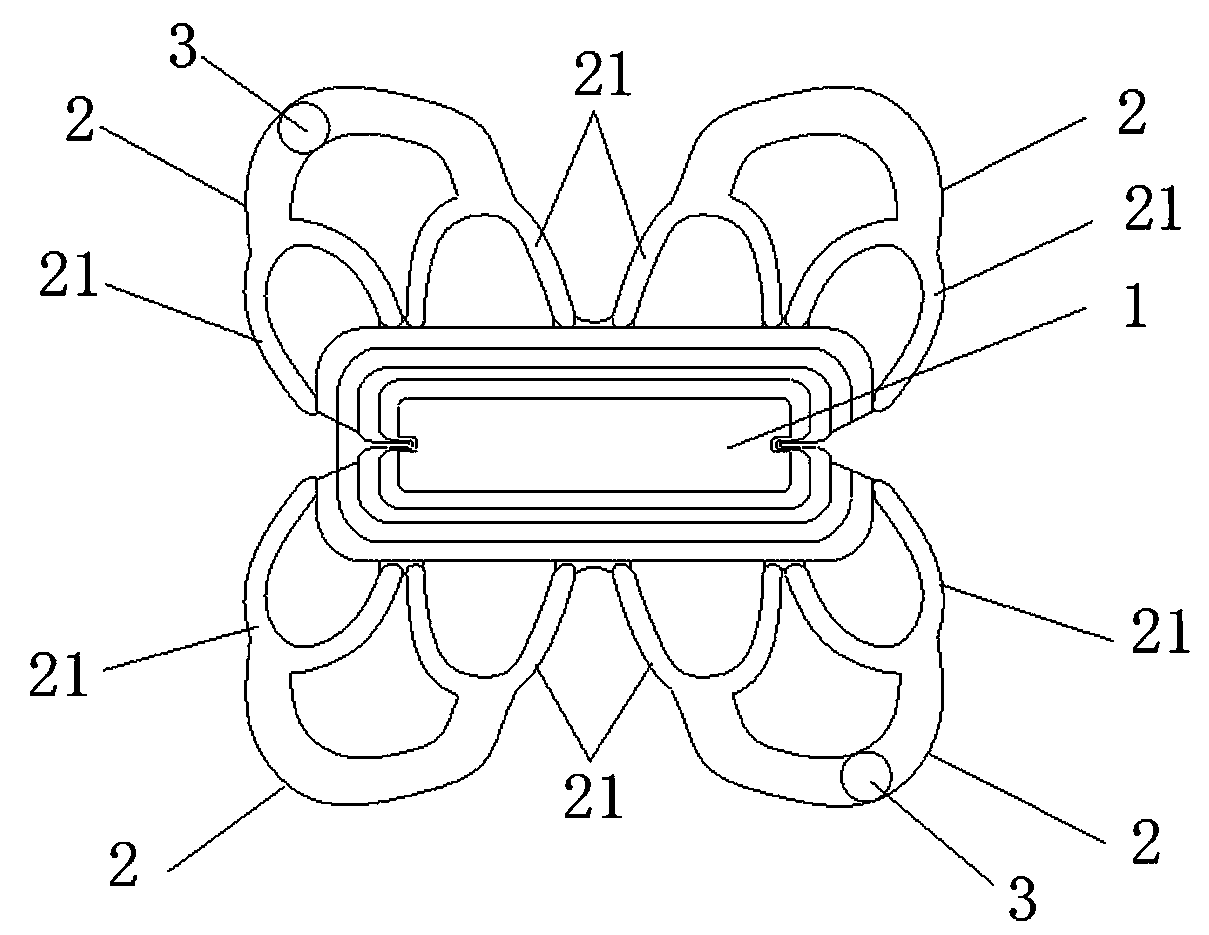

[0016] like figure 1 A device for making two-color co-extruded plastic wood flooring is shown, including a molding die and 2 co-extruders connected to the molding die, and the molding device includes a discharge port 1 and a 4 connected to the discharge port 1 A group of extruded tube groups 2 with the same shape, the two groups of extruded tube groups 2 are arranged above the discharge port 1, and the other two groups of extruded tube groups 2 are arranged below the discharge port 1, and are arranged on the discharge port 1. The extruded tube group 2 above and below the outlet 1 is mirror-symmetrical with the discharge port 1 as the axis, and the extruded tube group 2 arranged above or below the discharge port 1 is centered on the center line perpendicular to the length direction of the discharge port 1. Axial mirror symmetry, the two sets of extruded tube groups 2 located above or below the discharge port 1 are connected by pipes; the extruded tube group 2 includes two Y-sha...

Embodiment 2

[0018] With reference to Example 1, the extrusion port 3 of the co-extrusion machine is connected to the interconnection section of the two extruded tubes 21; It is axisymmetric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com