Rapidly disassembling and assembling side window structure

A side window, fast technology, applied in the field of car windows, can solve the problems of not being able to use curved glass, complicated costs, etc., and achieve good economic benefits, low cost, and optimize the installation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

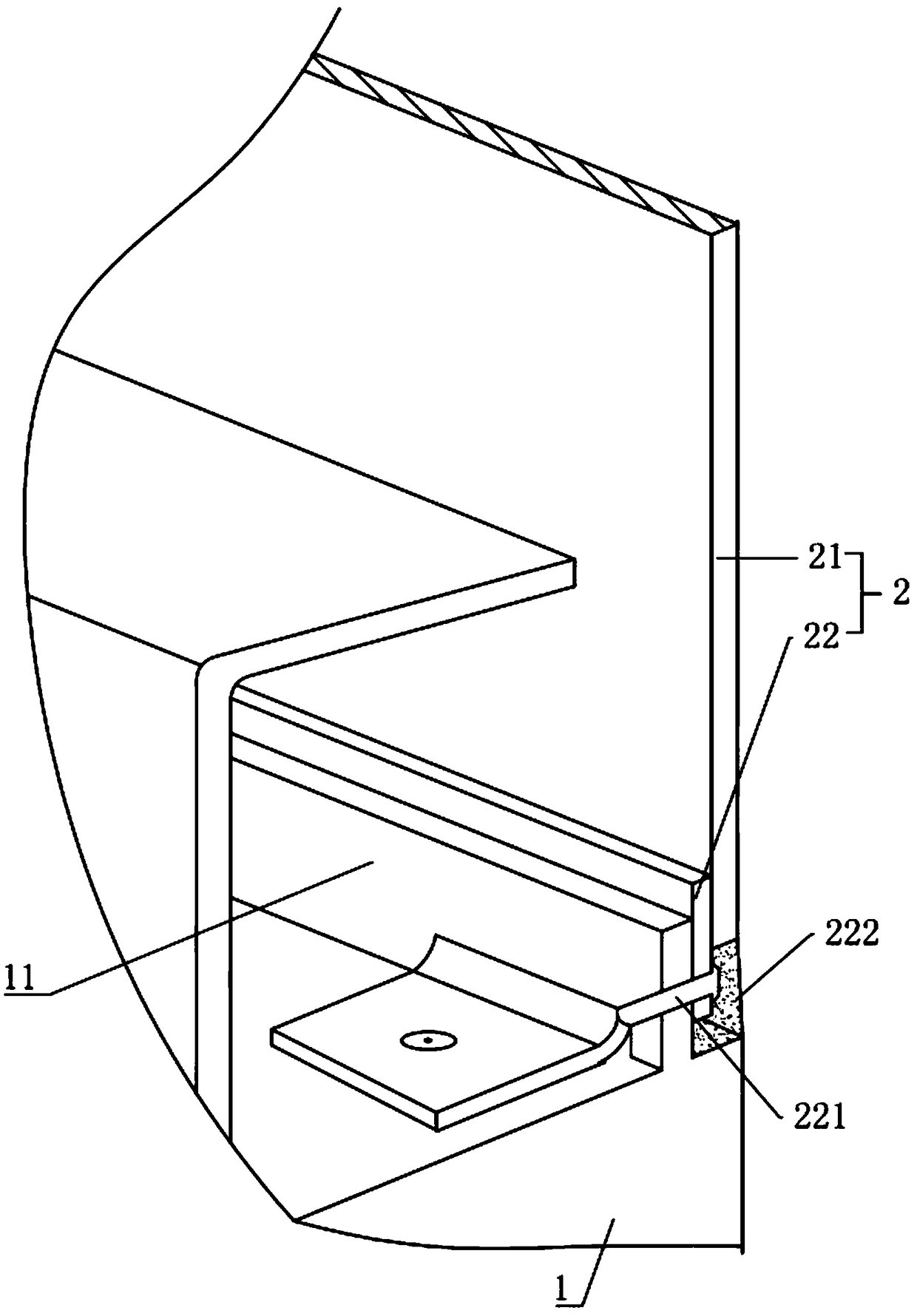

[0014] A side window structure that can be quickly disassembled, such as figure 1 As shown, a vehicle body 1 is included, a window frame 11 is arranged on the vehicle body 1, and a side window 2 is installed in the window frame 11. The side window 2 includes a glass window surface 21, and the peripheral side of the glass window surface 21 is provided with The frame 22 is connected to the window frame 11 through fasteners 221 .

[0015] The frame 22 is spliced by several aluminum laths. The frame 22 is arranged on the side of the glass window 21 close to the vehicle body 1 , and there is an installation seam between the glass window 21 and the vehicle body 1 , and the installation seam is filled with a sealant 222 . The glass window surface 21 and the frame 22 are bonded and fixed by adhesive glue.

[0016] Specific implementation instructions:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com