Production control system and method capable of achieving food quality traceability

A technology of production control and food quality, applied in the field of food quality traceability control system, can solve the problems of ineffective control and prevention of food quality, inability to accurately find the root of the problem, etc., and achieve the effect of realizing intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

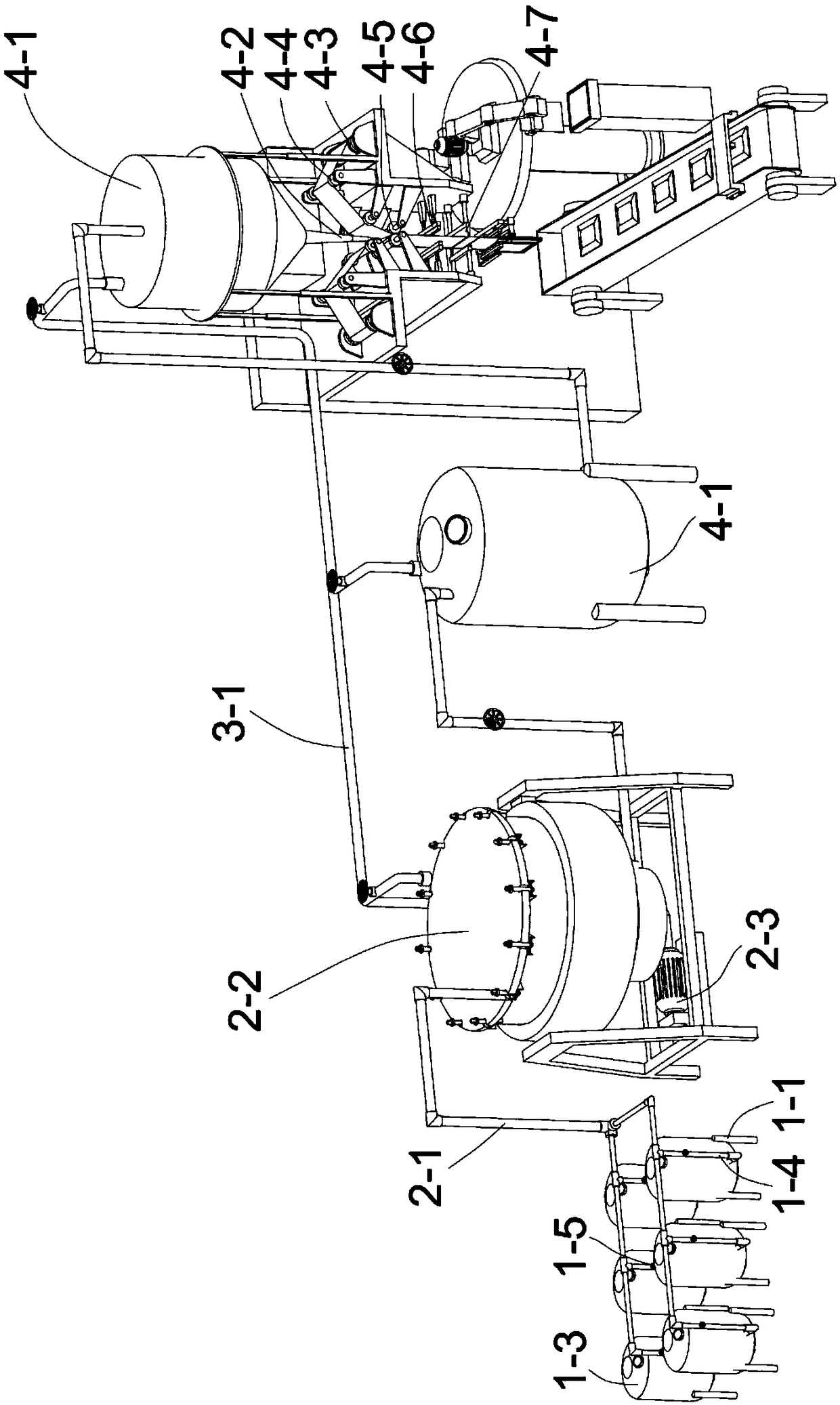

[0030] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

[0031] This embodiment takes the production of beef sauce as an example to specifically illustrate the implementation of the present invention.

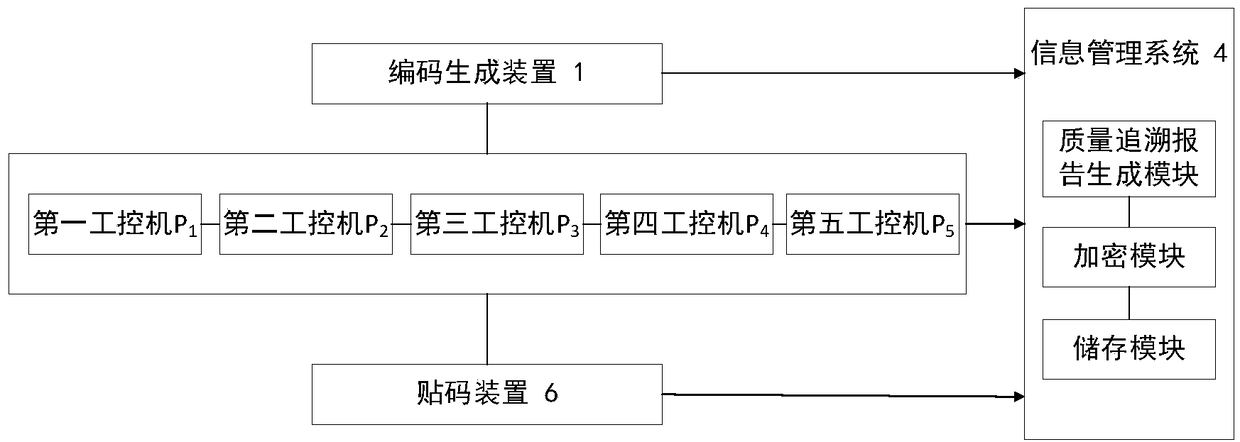

[0032] A production control system for realizing food quality traceability, comprising: a code generation device 1, a feeding device, and a first industrial computer P set on the feeding device 1 , the frying device, the second industrial computer P set on the frying device 2 , the cooling device, the third industrial computer P set on the cooling device 3 , the packaging device, the fourth industrial computer P set on the packaging device 4 , the code sticking device 6, the fifth industrial computer P connected with the code sticking device 6, the counter on the packaging device, and the code generating device 1 through the field bus mode 5 , and the code generation device 1, the first industrial computer P 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com