Calcium carbide conveying line and conveying track thereof

A technology of conveying rails and conveying lines, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as cost increase, and achieve the effect of improving reliability, reducing cost, and reducing the requirements of structural stability and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing.

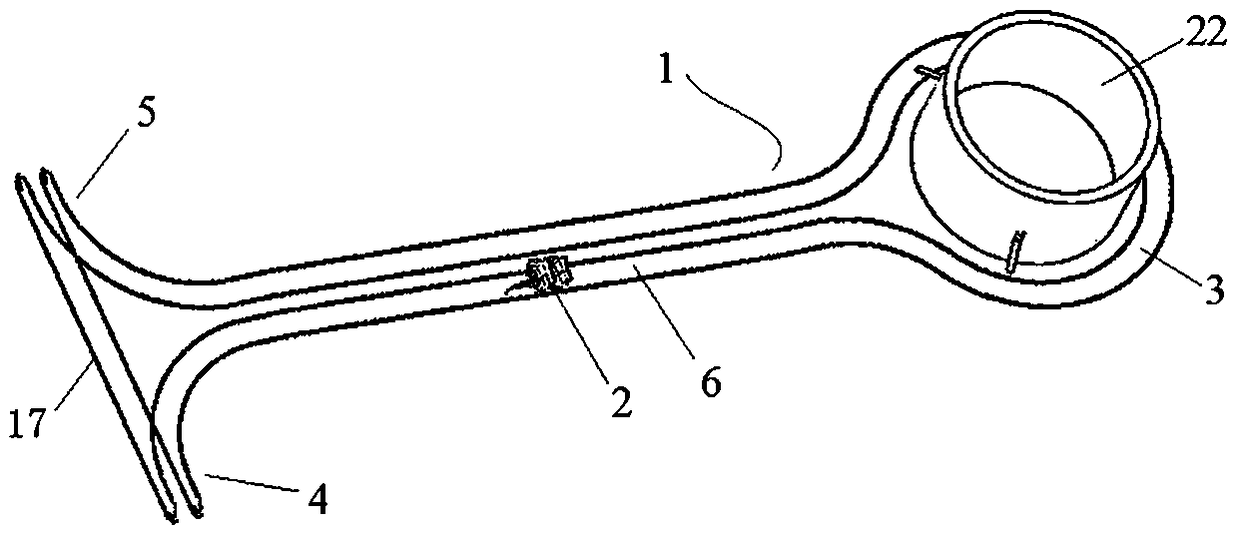

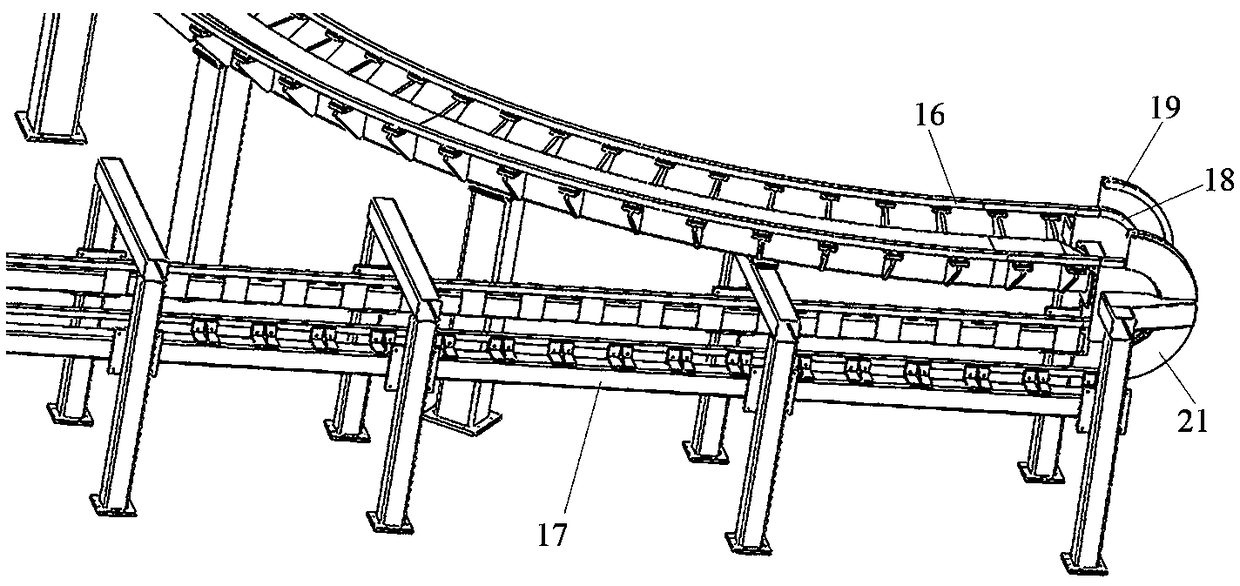

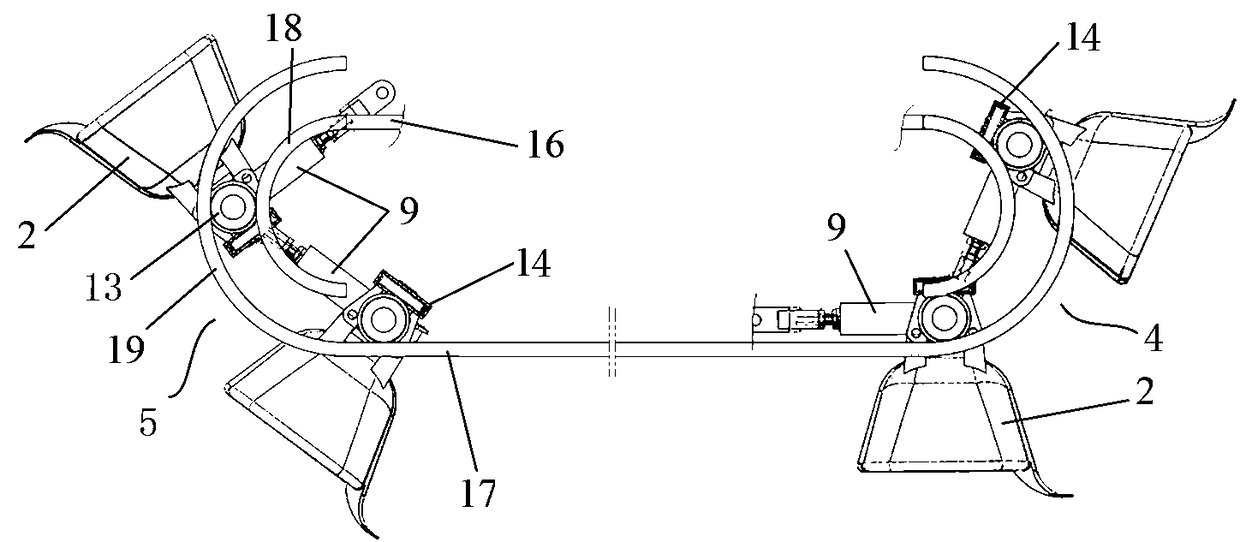

[0042] An embodiment of the calcium carbide transmission line in the present invention is as Figure 1 to Figure 11 As shown, it includes a conveying track 1 and a calcium carbide trolley 2. The conveying track 1 includes two guide rails arranged side by side, and is a closed track. The material part 4, the reset part 5 that powers the stone trolley 2 to turn up and reset, and the ramp part 6 that is connected between the surrounding part 3 and the unloading part 4 and the surrounding part 3 and the reset part 5. The calcium carbide trolley 2 includes a frame 7 and a calcium carbide pot 8 fixed on the frame 7. The frame 7 includes a fixing seat for fixing the calcium carbide pot 8 and a connecting rod 9 fixedly connected with the fixing seat. The connecting rod 9 is a cylindrical structure , the front end and the rear end are respectively provided with hinged holes, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com