Preparation method of rapid-responding photochromic gel film material

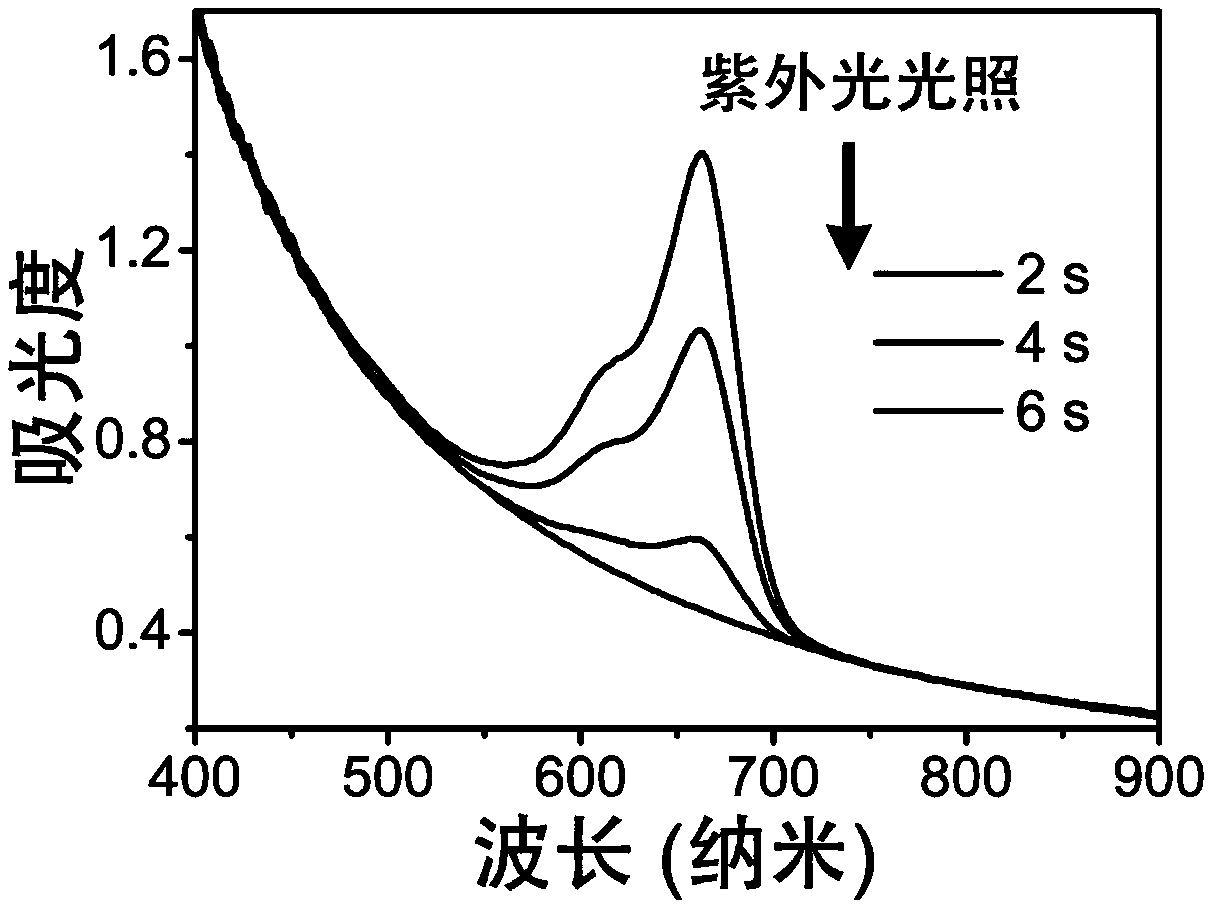

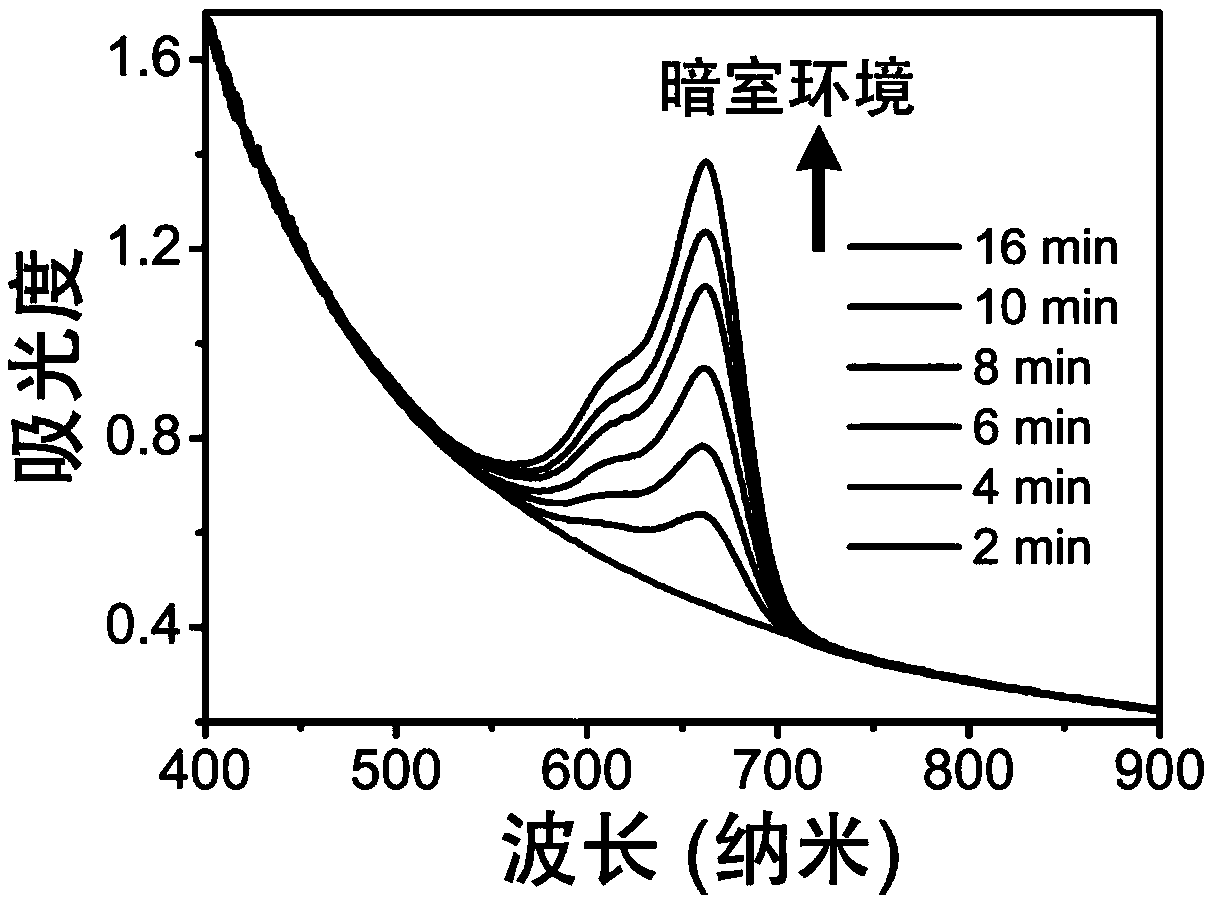

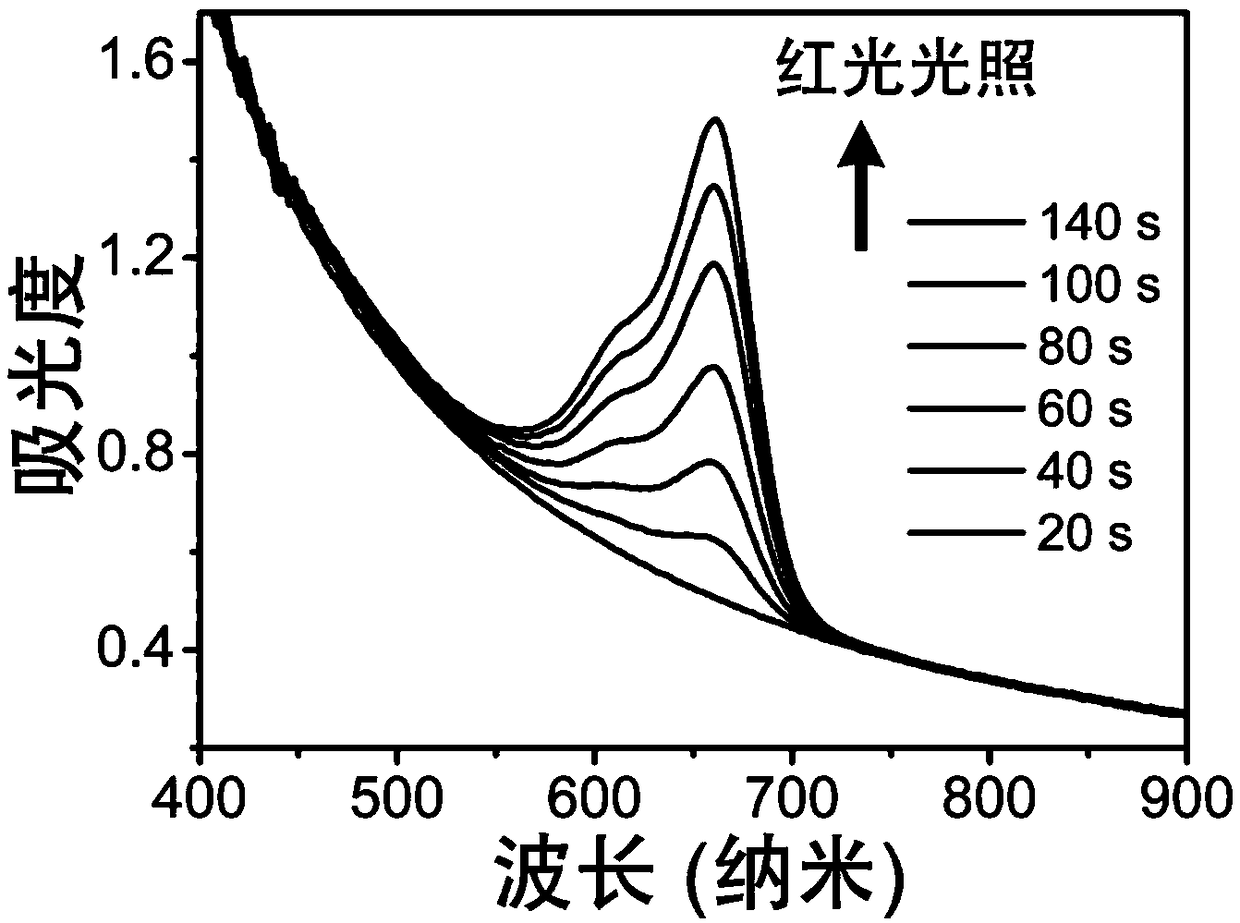

A photochromic, fast-response technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of complex and cumbersome preparation methods, poor uniformity and stability of hydrogel, etc., and achieve simple synthesis process, reversible High color efficiency and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of a photochromic gel film material, the specific steps are as follows:

[0037] (1) Take 30 mg of SnO 2 Nanoparticles, dispersed in 2 mL of deionized water, added 30 μL of methylene blue (MB) aqueous solution (0.01 M) and 1 mL of ethylene glycol (EG);

[0038] (2) Add 6g of polyvinyl alcohol (PVA) powder with a molecular weight of 13w and 94mL of deionized water into a 100mL three-necked flask, stir magnetically and heat at 70°C for 3h;

[0039] (3) Add 3 mL of dissolved PVA aqueous solution to the well-mixed SnO 2 / MB / EG solution, ultrasonically shake; add 0.02-0.6g phosphoric acid and 0.1-10μL 0.0426mol / L glutaraldehyde solution to the system, and ultrasonically stir for 10min;

[0040] (4) drop the solution obtained in step (3) on 5*6cm 2 The photochromic gel film material was obtained by drying at 40° C. for 4 h on a glass substrate or a PET substrate.

Embodiment 2

[0042] A preparation method of a photochromic gel film material, the specific steps are as follows:

[0043] (1) Take 30 mg of SnO 2 Nanoparticles, dispersed in 2 mL of deionized water, added 30 μL of neutral red aqueous solution (0.01 M) and 1 mL of ethylene glycol;

[0044] (2) Add 1 g of polyethylene oxide (PEO) powder with a molecular weight of 50w and 99 mL of deionized water into a 100 mL three-necked flask, stir magnetically and heat at 70°C for 3 hours;

[0045] (3) Add 3 mL of dissolved PEO aqueous solution to the well-mixed SnO 2 / NR / EG solution, ultrasonic vibration;

[0046] (4) Add an appropriate amount of peroxide initiator and vinyl monomer to the solution obtained in step (3), and mix them well; drop the obtained solution on 5*6cm 2 The photochromic gel film material was obtained by drying at 40° C. for 4 h on a glass substrate or a PET substrate.

Embodiment 3

[0048] A preparation method of a photochromic gel film material, the specific steps are as follows:

[0049] (1) Take 30mg of MnO 3Nanoparticles, dispersed in 2mL of deionized water, added 30μL of neutral red aqueous solution (0.01M) and 1mL of polyethylene glycol 400;

[0050] (2) Add 2g of polyethylene oxide (PEO) powder with a molecular weight of 20w and 98mL of deionized water into a 100mL three-necked flask, stir magnetically and heat at 70°C for 3h;

[0051] (3) Add 3 mL of dissolved PEO aqueous solution to the homogeneously mixed MnO 2 / NR / PEG 400 solution, ultrasonic vibration;

[0052] (4) Add an appropriate amount of peroxide initiator and vinyl monomer to the solution obtained in step (3), and mix them well; drop the obtained solution on 5*6cm 2 The photochromic gel film material was obtained by drying at 40° C. for 4 h on a glass substrate or a PET substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com