A crystalline tungsten trioxide/titanium doped amorphous tungsten oxide nanowire array and its preparation method

A tungsten oxide nanowire and tungsten trioxide nanotechnology, which is applied in the field of crystalline tungsten trioxide/titanium-doped amorphous tungsten oxide nanowire array and its preparation, can solve the problems of slow discoloration, poor cycle stability, and coloring efficiency. Low-level problems, to achieve the effect of fast response, long cycle life and high coloring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

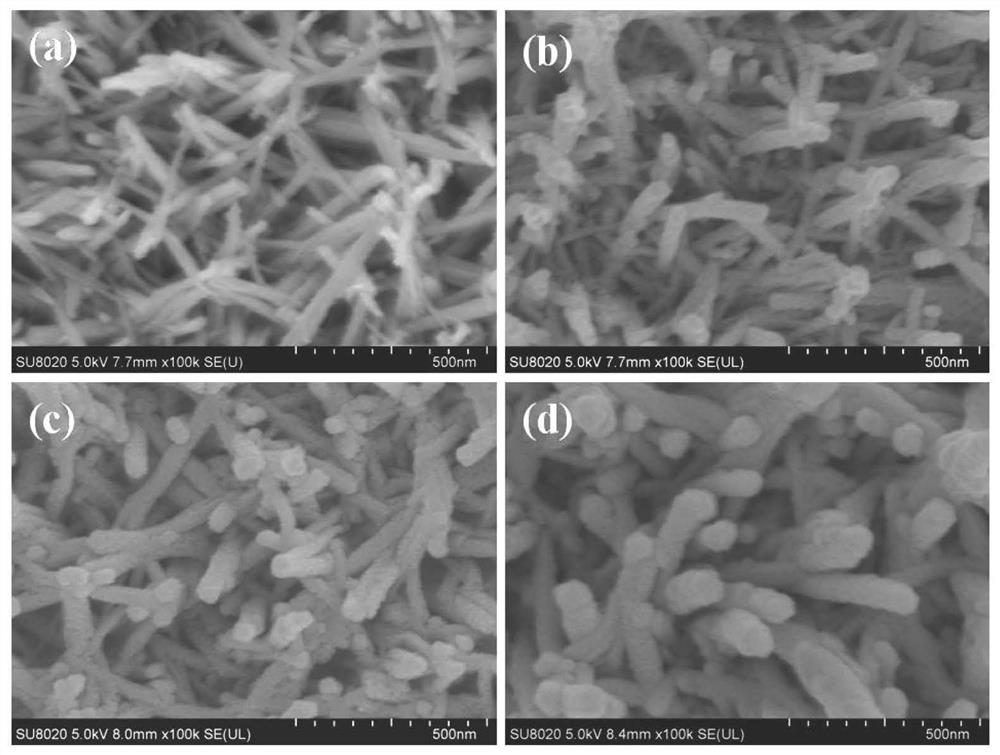

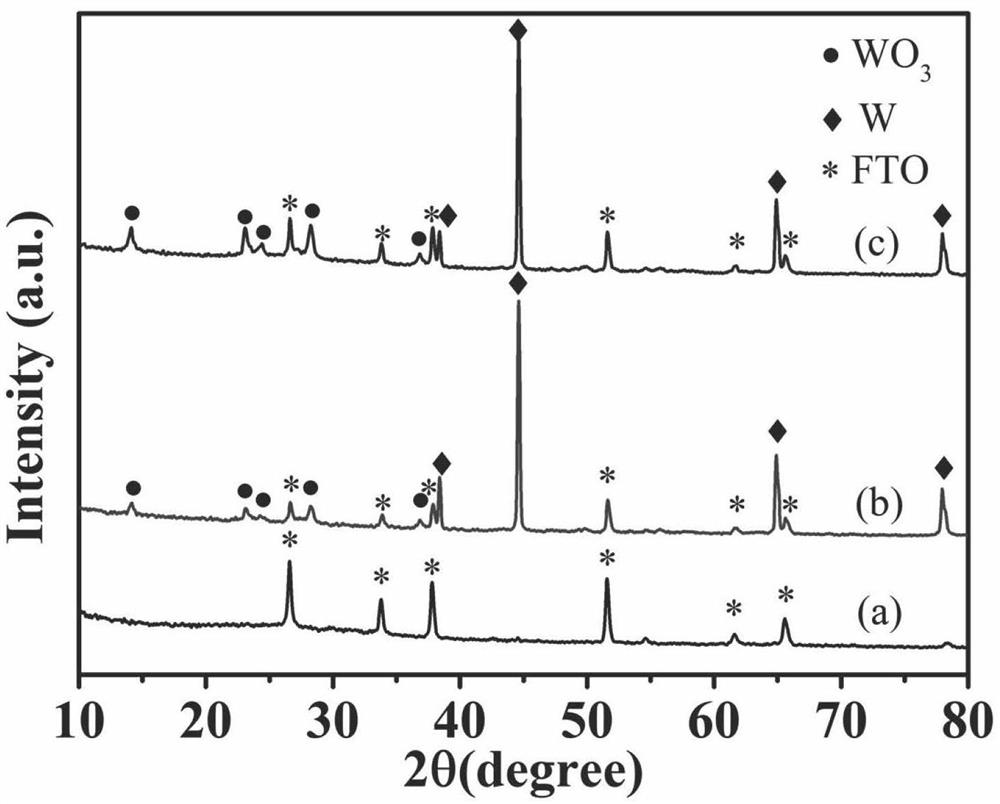

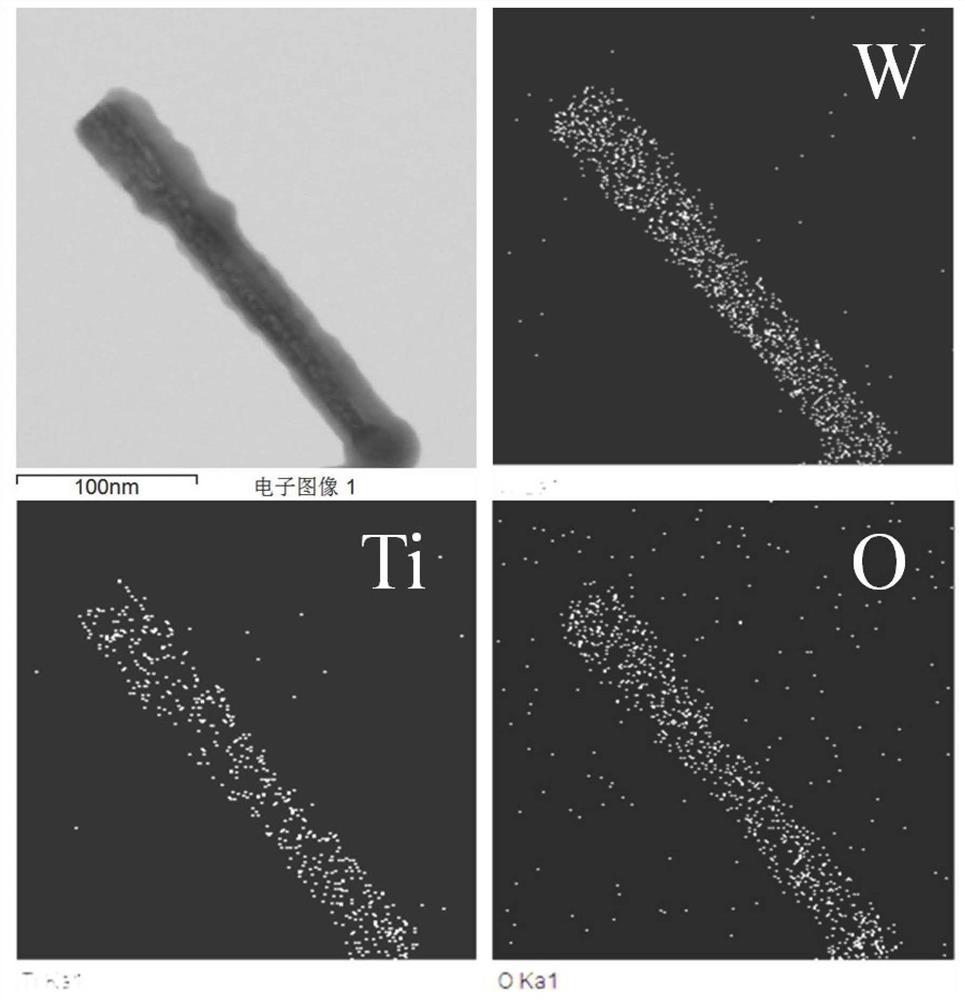

Embodiment 1

[0037] A preparation method of crystalline tungsten trioxide / titanium doped amorphous tungsten oxide nanowire array, the specific steps are as follows:

[0038] (1) Place the FTO conductive glass in a beaker filled with acetone, ethanol, and deionized water in turn, and ultrasonicate for 30 minutes respectively, and then put it on filter paper and dry it with an infrared lamp;

[0039] (2) Put the FTO conductive glass cleaned in step (1) on the sample stage of the vacuum chamber of the magnetron sputtering coating system, then place the tungsten trioxide target with a purity of 99.99% on the radio frequency sputtering target position, Adjust the distance between the target and the FTO conductive glass to 5cm; vacuumize until the vacuum in the vacuum chamber reaches 2.0*10 -4 When Pa is below, enter 50 sccm of argon gas and 50 sccm of oxygen gas, adjust the pressure of the vacuum chamber to 0.8 Pa, turn on the radio frequency sputtering control system, sputter a layer of tungst...

Embodiment 2

[0046] A preparation method of crystalline tungsten trioxide / titanium doped amorphous tungsten oxide nanowire array, the specific steps are as follows:

[0047] (1) Place the FTO conductive glass in a beaker filled with acetone, ethanol, and deionized water in turn, and ultrasonicate for 30 minutes respectively, and then put it on filter paper and dry it with an infrared lamp;

[0048] (2) Put the FTO conductive glass cleaned in step (1) on the sample stage of the vacuum chamber of the magnetron sputtering coating system, then place the tungsten trioxide target with a purity of 99.99% on the radio frequency sputtering target position, Adjust the distance between the target and the FTO conductive glass to 5cm; vacuumize until the vacuum in the vacuum chamber reaches 2.0*10 -4 When Pa is below, enter 50 sccm of argon gas and 50 sccm of oxygen gas, adjust the pressure of the vacuum chamber to 0.8 Pa, turn on the radio frequency sputtering control system, sputter a layer of tungst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Coloring time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com