A method of controlling the magnetic domain of fega magnetostrictive alloy by unidirectional solidification stress

A technology of directional solidification and alloying, applied in the direction of self-solidification method, chemical instruments and methods, single crystal growth, etc., can solve the problems such as being unsuitable for processing large-size samples, high requirements for heat treatment equipment, uneven magnetic field distribution, etc., to achieve comprehensive use The effect of good performance, convenient operation and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The steps adopted in this embodiment are as follows:

[0034] 1. Ingredients

[0035] The purity of the selected raw materials Fe and Ga are both 99.99wt%, and in order to prevent the Ga element from burning during the smelting process, the Fe 81 Ga 19 2wt% Ga was added on the basis of the composition. Specifically, 1547.1 g of Fe and 461.8 g of Ga were weighed for use. Before batching, Fe must be ultrasonically cleaned with absolute ethanol and dried under vacuum to remove the oil on the surface.

[0036] 2. Preparation of master alloy ingot

[0037] Put the above-mentioned weighed raw materials Fe and Ga into the crucible of the vacuum non-consumable arc melting furnace. When placing it, it is necessary to place the Ga element that is easy to burn at the bottom of the crucible, and the Fe element that is not easy to burn at the top of the crucible.

[0038] Vacuumize the vacuum non-consumable arc melting furnace to 5.0×10 -2 After Pa, fill the furnace body with ...

Embodiment 2

[0051] 1. The steps of batching, preparation of master alloy ingot and preparation of master alloy rod in this embodiment are the same as in embodiment 1.

[0052] 2. In the step of preparing FeGa alloy by directional solidification, heat the graphite heating body to 800 °C at a heating rate of 30 °C / min, heat the graphite heating body to 1625 °C at a heating rate of 25 °C / min after holding for 5 minutes, and then keep it for 30 minutes . The growth rate is controlled at 5mm / h, and the corundum crucible is pulled down steadily into the liquid alloy for directional solidification. After the directional growth is finished, the temperature of the directional furnace is lowered to room temperature, and then the grown FeGa alloy is taken out.

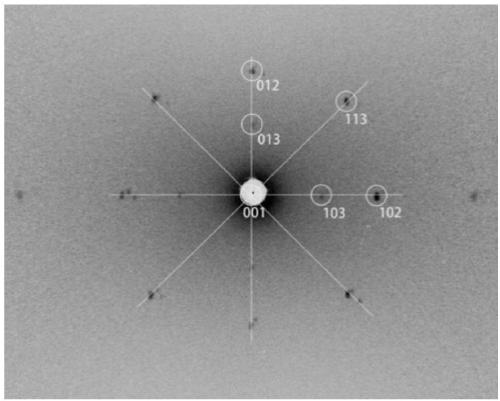

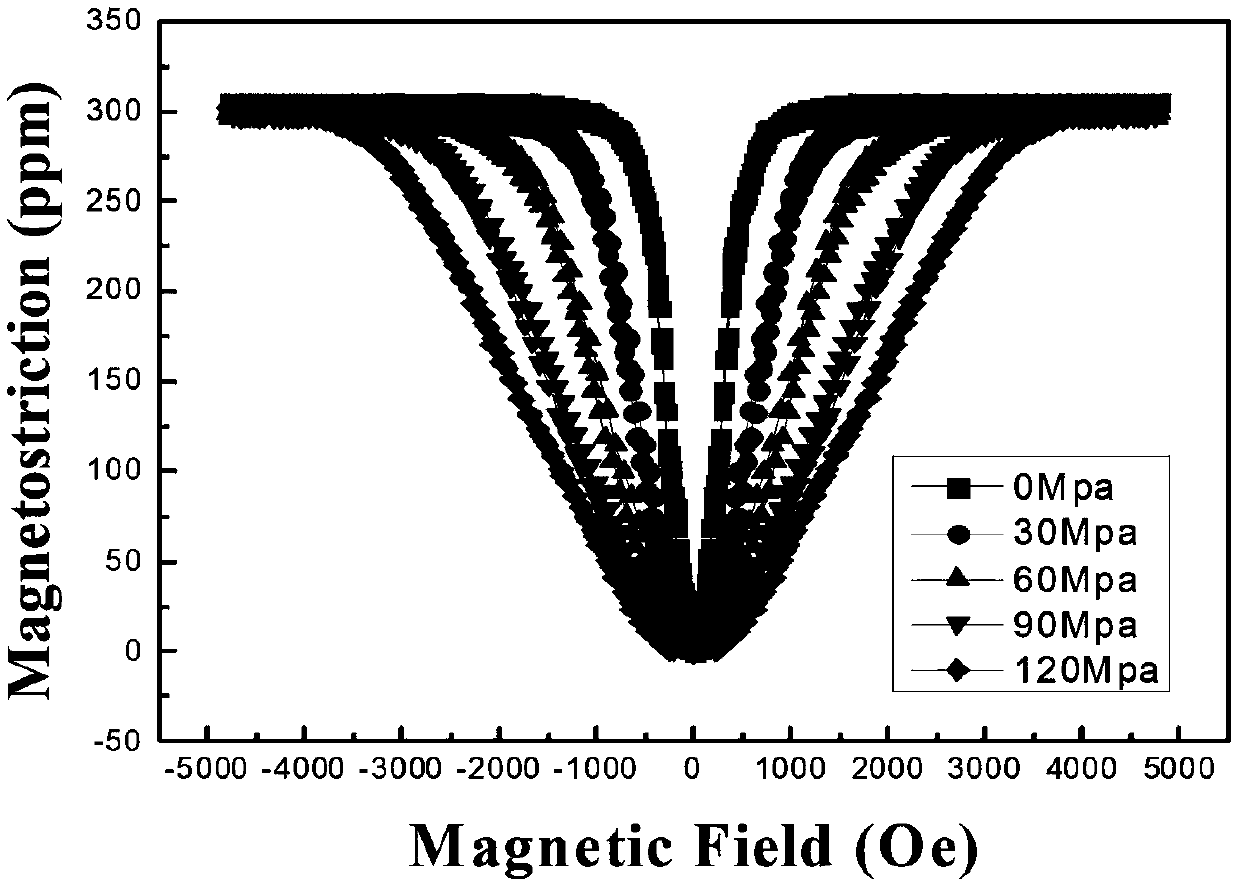

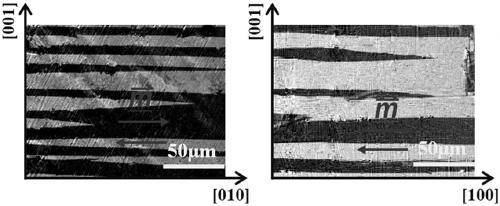

[0053] 3. The orientation of the obtained FeGa alloy is the [001] direction, the magnetic domains are arranged perpendicular to the growth direction, and the width is 70-120 μm; the magnetostriction coefficient of the FeGa alloy is 305ppm u...

Embodiment 3

[0055] 1. The steps of batching, preparation of master alloy ingot and preparation of master alloy rod in this embodiment are the same as in embodiment 1.

[0056] 2. In the step of preparing FeGa alloy by directional solidification, heat the graphite heating body to 800 °C at a heating rate of 30 °C / min, heat the graphite heating body to 1625 °C at a heating rate of 25 °C / min after holding for 5 minutes, and then keep it for 30 minutes . The growth rate is controlled at 50mm / h, and the corundum crucible is pulled down steadily into the liquid alloy for directional solidification. After the directional growth is finished, the temperature of the directional furnace is lowered to room temperature, and then the grown FeGa alloy is taken out.

[0057] 3. The orientation of the obtained FeGa alloy is the [001] direction, the magnetic domains are arranged perpendicular to the growth direction, and the width is 60-90 μm; the magnetostriction coefficient of the FeGa alloy is 311ppm u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com