High-efficiency acoustic panel

A sound insulation board, a high-efficiency technology, applied in the direction of sound insulation, building components, etc., can solve the problems of increased discomfort for workers, high noise in the working environment, and no sound insulation effect, etc., to achieve good sound insulation effect, enhanced sound absorption effect, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

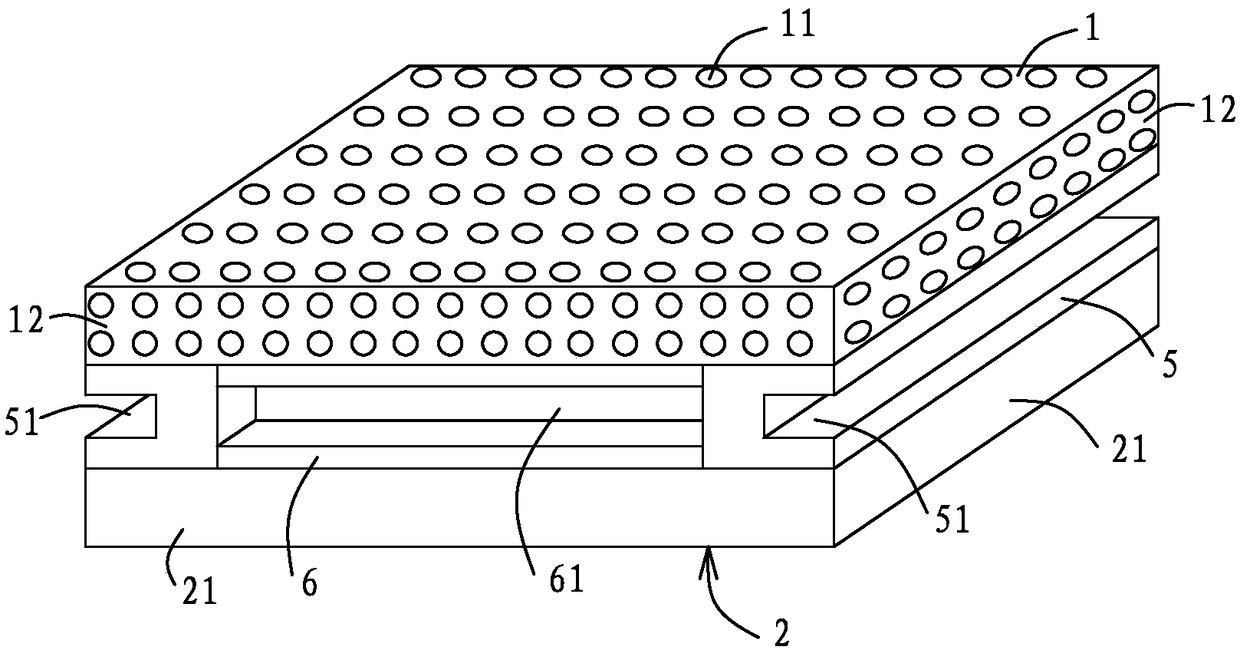

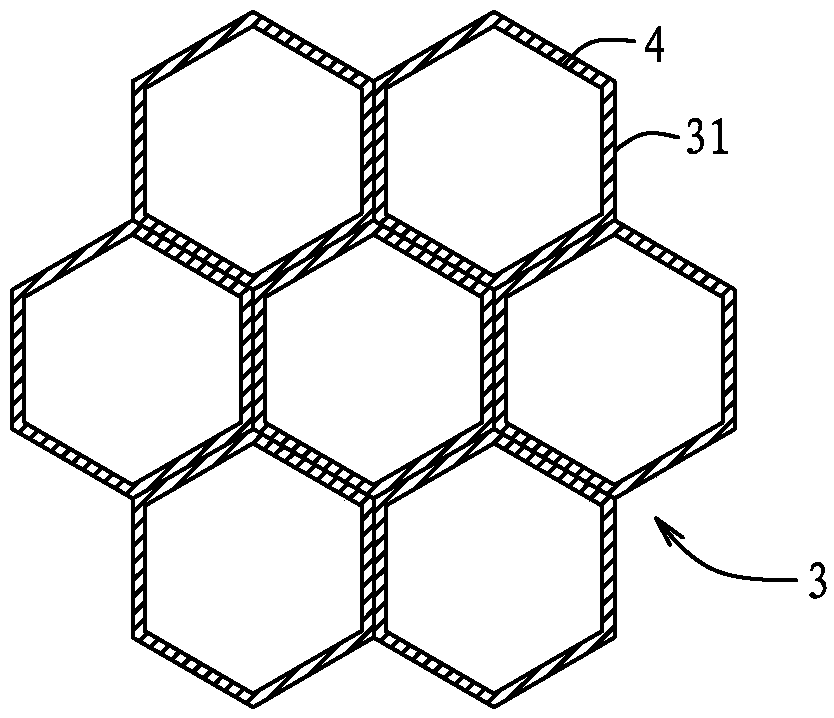

[0017] refer to figure 1 and figure 2 : High-efficiency sound insulation board, including a first panel 1, a second panel 2 and an aluminum honeycomb core 3, the first panel 1 and the second panel 2 are respectively arranged on opposite sides of the aluminum honeycomb core 3, and the aluminum honeycomb core 3 includes A plurality of spliced sound-absorbing units 31 are provided with a resin layer 4 on the inner wall of each sound-absorbing unit 31 . The resin layer 4 and the sound-absorbing unit 31 are bonded and fixed by resin foaming and curing. During production, the aluminum honeycomb core 3 can be soaked in a resin solution, and then foamed and cured, so that the sides of the resin layer 4 and the sound-absorbing unit 31 The walls are bonded and fastened; the thickness of the resin layer 4 is 0.3-1mm, thus, the noise can be absorbed to a certain ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com