Operation space-limited wallboard assembly and operation space-limited wallboard assembling method

A technology for operating space and assembly methods, applied in the direction of building components, buildings, building structures, etc., can solve problems affecting physical properties, troublesome construction process, and damage to wall structures, etc., and achieve the effect of good safety and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

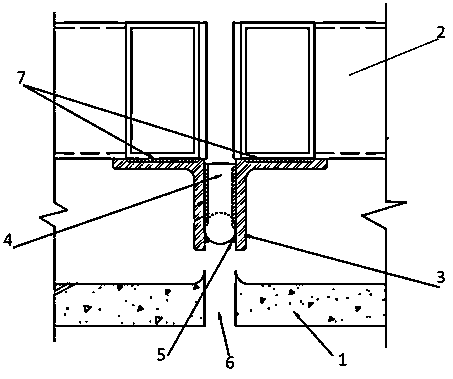

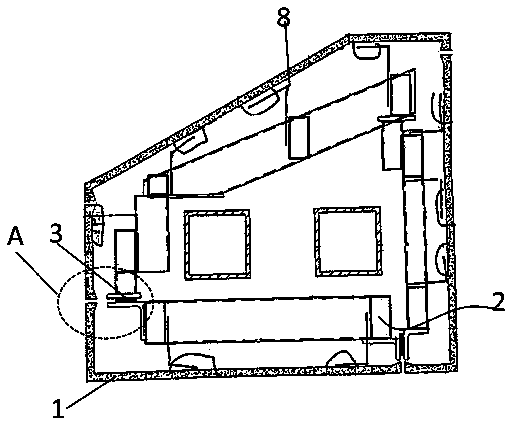

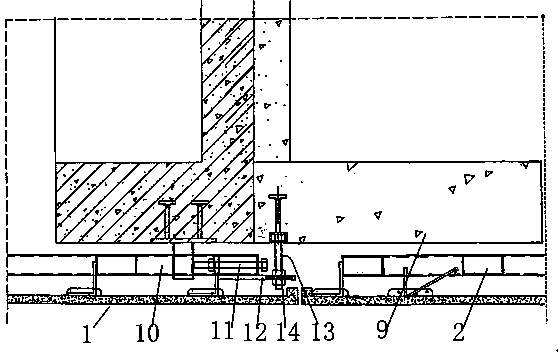

[0031] combine Figure 1 to Figure 5 , describe the structure, principle and advantages of the present invention in detail. In order to solve the problems existing in the background technology, the applicant conducted in-depth research and analysis, and sorted out the advantages and disadvantages of existing patents and papers. A new solution is provided.

[0032] like figure 1 and figure 2 As shown, when assembling a cylindrical or cylindrical-like shape (the cross-sectional shape can be trapezoidal, square, circular, elliptical or similar), especially when installing the last plate, there are great difficulties due to the installation and operation space Very little or none at all. In response to this situation, it is very difficult to use clamping, first destroying and then repairing, or entering the inner space from above, so a new structure needs to be designed. figure 2 A in the, and figure 1 The difference is that one of the welding parts uses square tubes and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com