Electric locomotive air feeding fan testing tool equipment

A technology for blower fans and electric locomotives, applied in mechanical equipment, machine/engine, pump control, etc., can solve the problems of long procurement cycle and high cost and price of customized equipment, and achieve strong promotion and application value, strong practicability, and novel design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

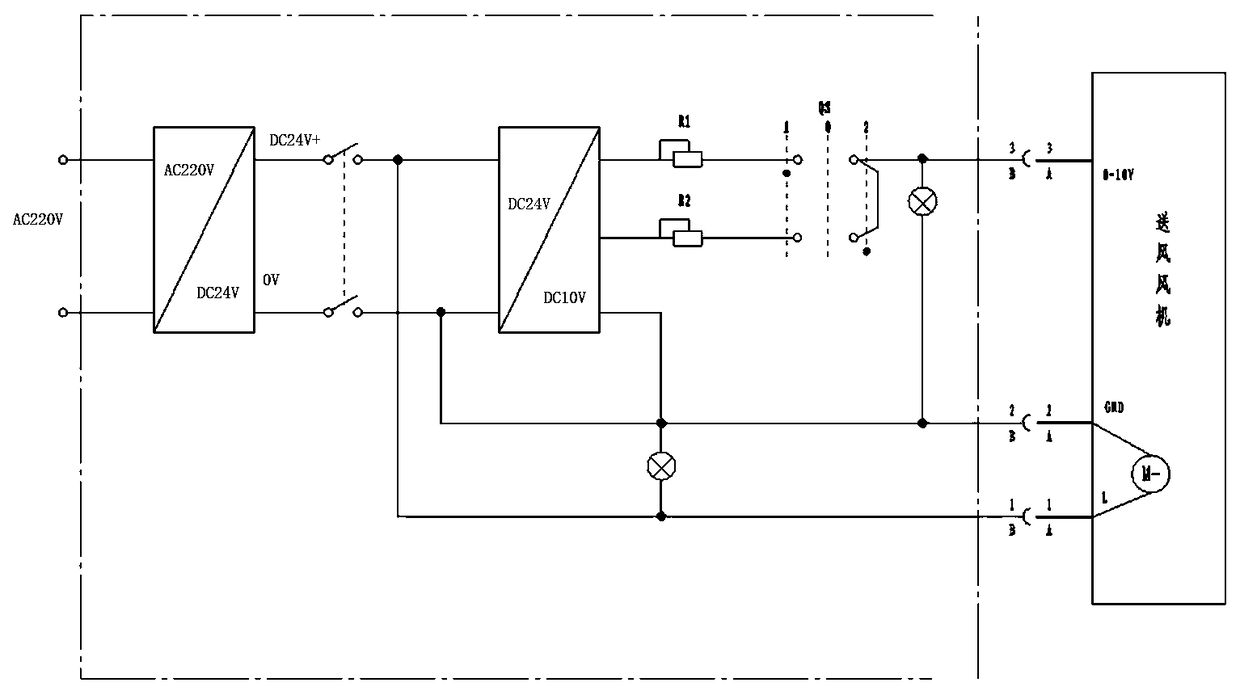

Method used

Image

Examples

Embodiment Construction

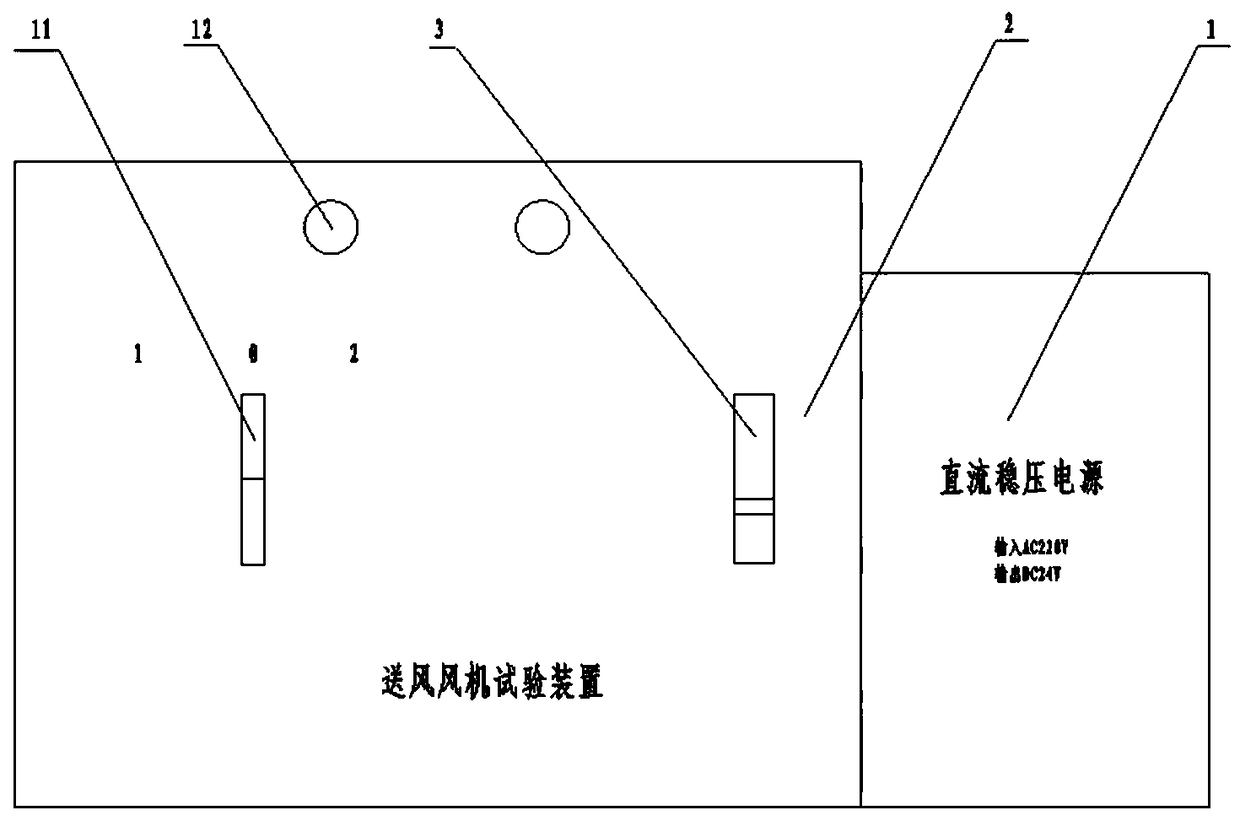

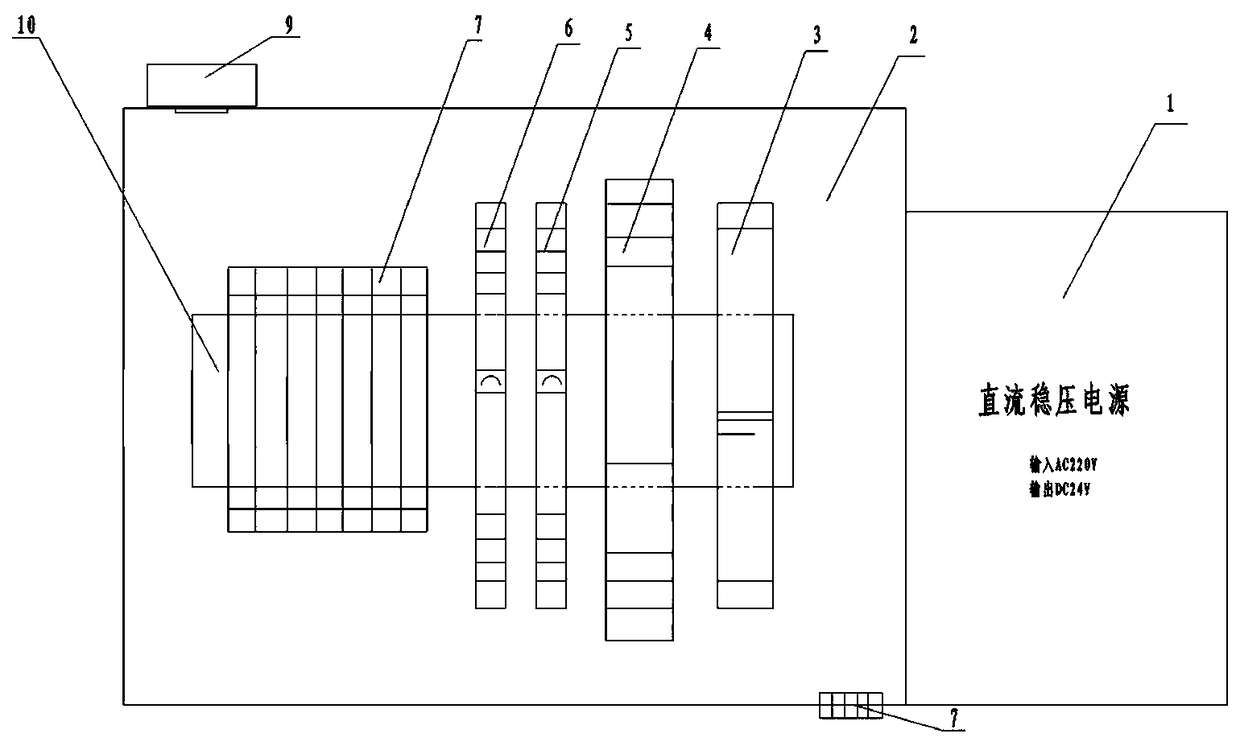

[0020] Numbers in the figure, number 1 stands for DC regulated power supply, number 2 stands for test tooling module, number 3 stands for control switch, number 4 stands for terminal power module, number 5 and 6 represent terminal adjustable resistors, number 7 stands for input terminal block The structure, the number 8 represents the terminal block structure, the number 9 represents the connector structure, the number 10 represents the installation guide rail, the number 11 represents the conversion control switch, and the number 12 represents the status indicator light.

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and technical solutions, and the implementation of the present invention will be described in detail through preferred embodiments, but the implementation of the present invention is not limited thereto.

[0022] In view of the high cost, long period, and inconvenient operation in the maintena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com