Spiral turbulent-flow blade based emitting device barrel cooling water jacket

A launcher and spoiler vane technology, which is applied in the field of the barrel cooling water jacket of the launcher, can solve the problems of no direction and regularity of the cooling water flow, uneven cooling of the barrel, and poor cooling effect of the lower part, etc., to achieve convenient descaling and maintenance, uniform cooling, avoiding the effect of flow dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

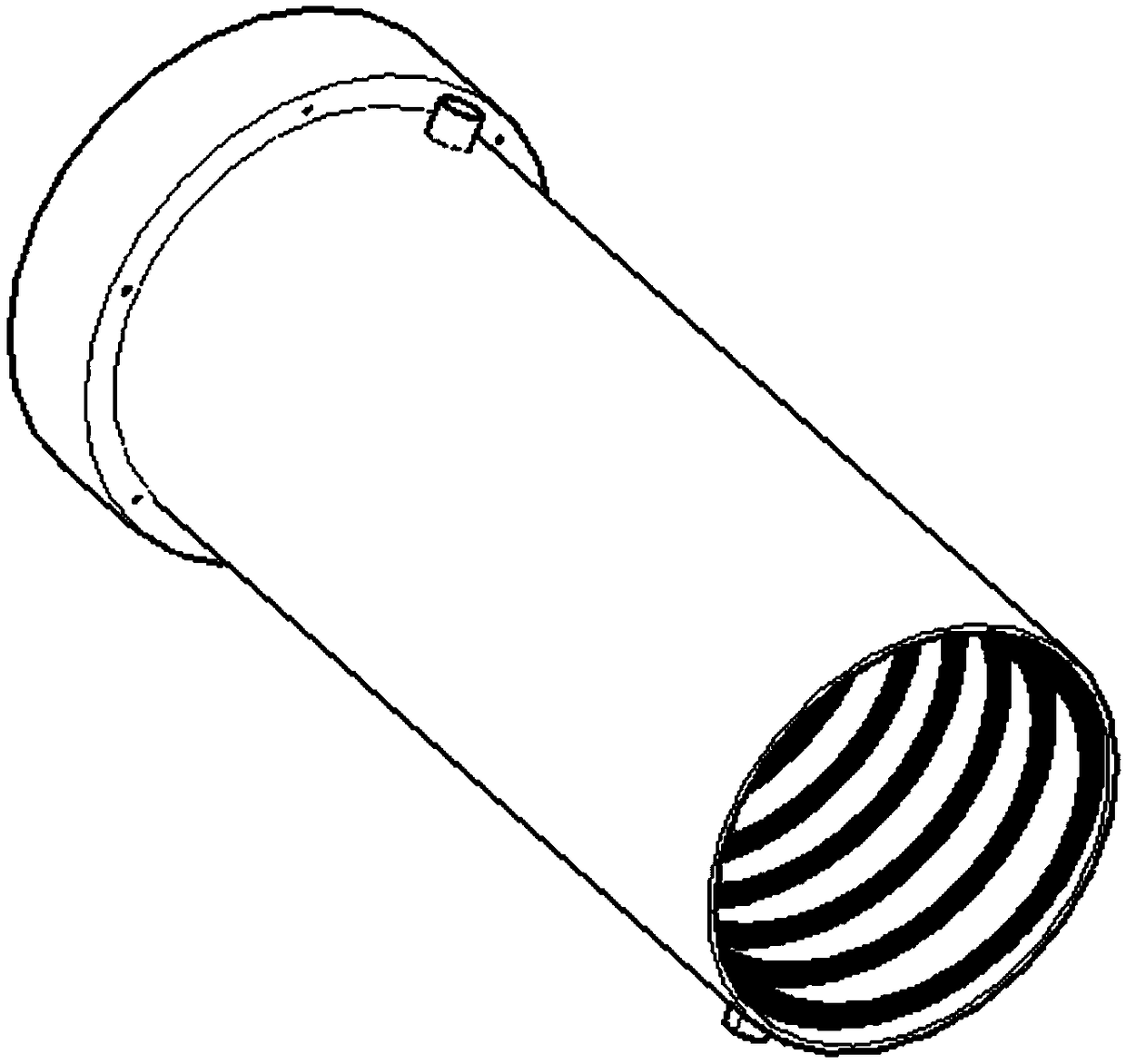

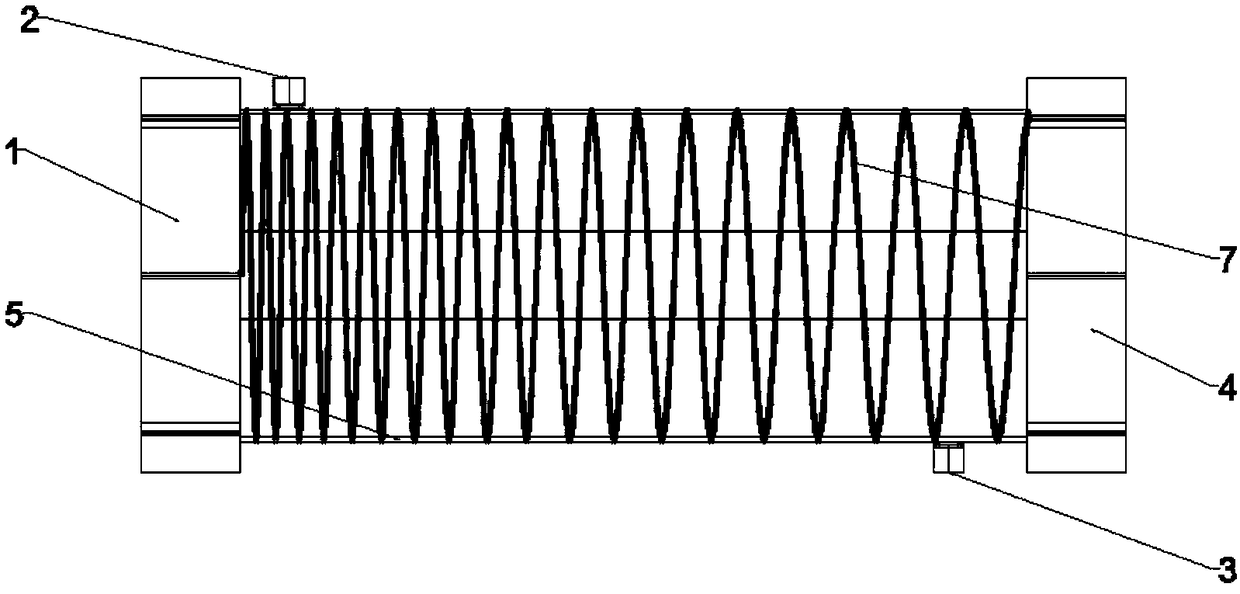

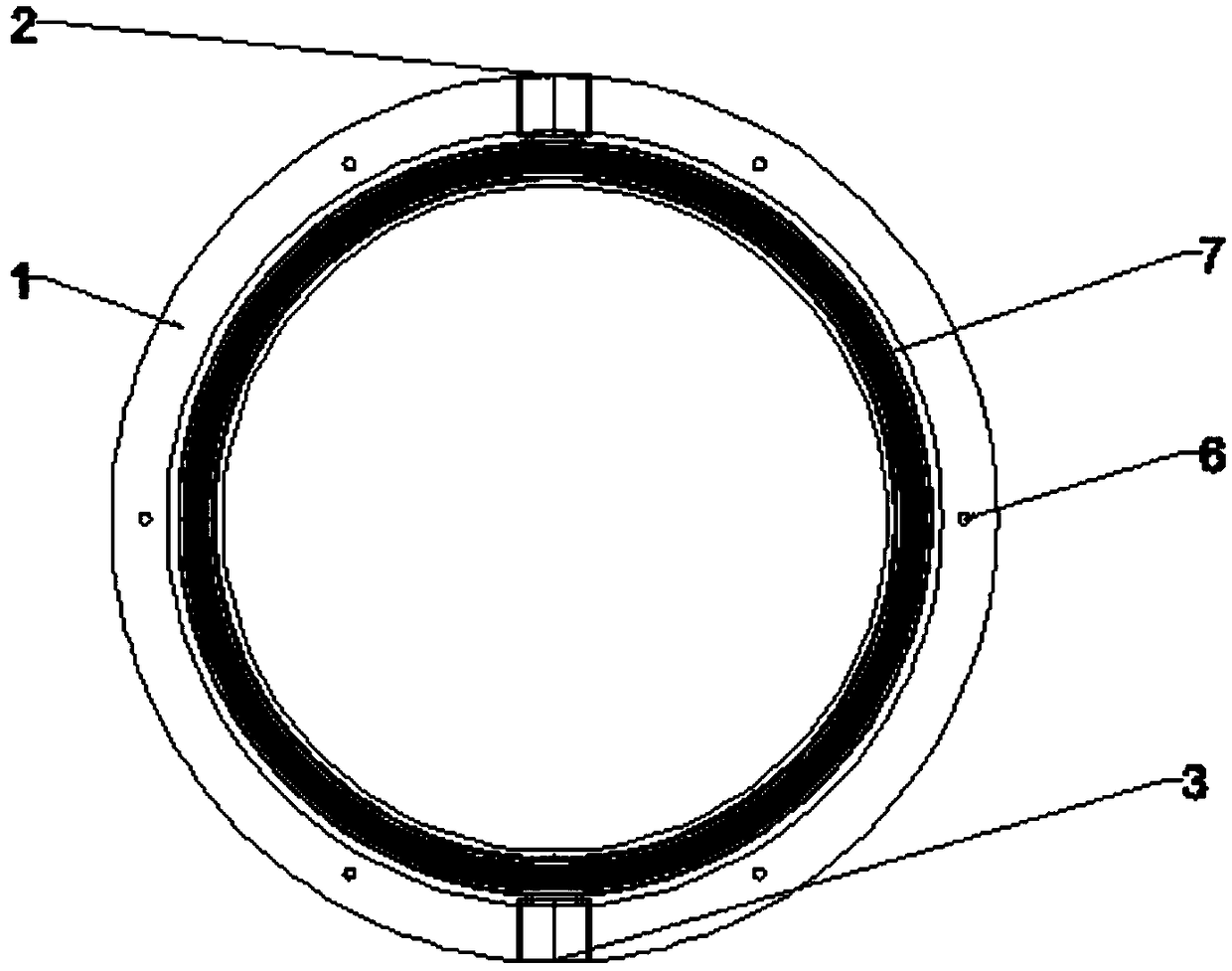

[0015] combine Figure 1 to Figure 3 , a barrel cooling water jacket for launching devices based on spiral spoiler blades, comprising an upper fixing part 1, a water jacket body 5, a lower fixing part 4, and an interface sealing gasket; the upper fixing part 1 is used to connect the water jacket body 5 to the The upper part of the body tube is fixed; the upper part of the water jacket body has a water inlet hole 2, and the lower part has a water outlet hole 3; the lower fixing part 4 is used to fix the water jacket body 5 and the lower body tube; an interface sealing gasket is installed at each interface; The water jacket body 5 has spiral spoiler blades 7 .

[0016] The cooling water flow in the cooling water jacket 5 covers the entire barrel surface.

[0017] The upper fixing part 1 and the lower fixing part 4 are cylindrical, and a through hole through which the barrel of the launching device passes is provided along the axial direction, and the barrel of the launching dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com