MEMS safety system integrated device applied to small-caliber bomb and method thereof

A safety system and small-caliber technology, which is applied in the field of MEMS safety system integration devices, can solve the problem that the fuze safety system is too large in size, the space allocation of the fuse system is insufficient, the degree of integration and integration technology is not high, and the space allocation of the fuse system is wasted. problems, to achieve the effect of improving damage efficiency, good consistency of processed samples, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

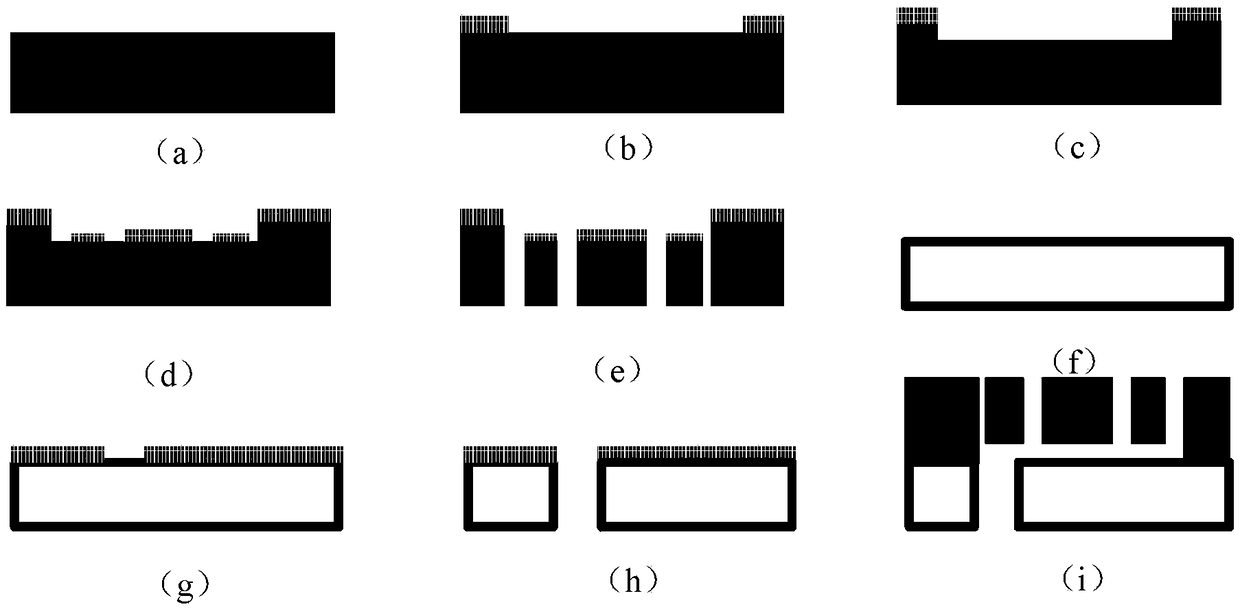

[0037] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

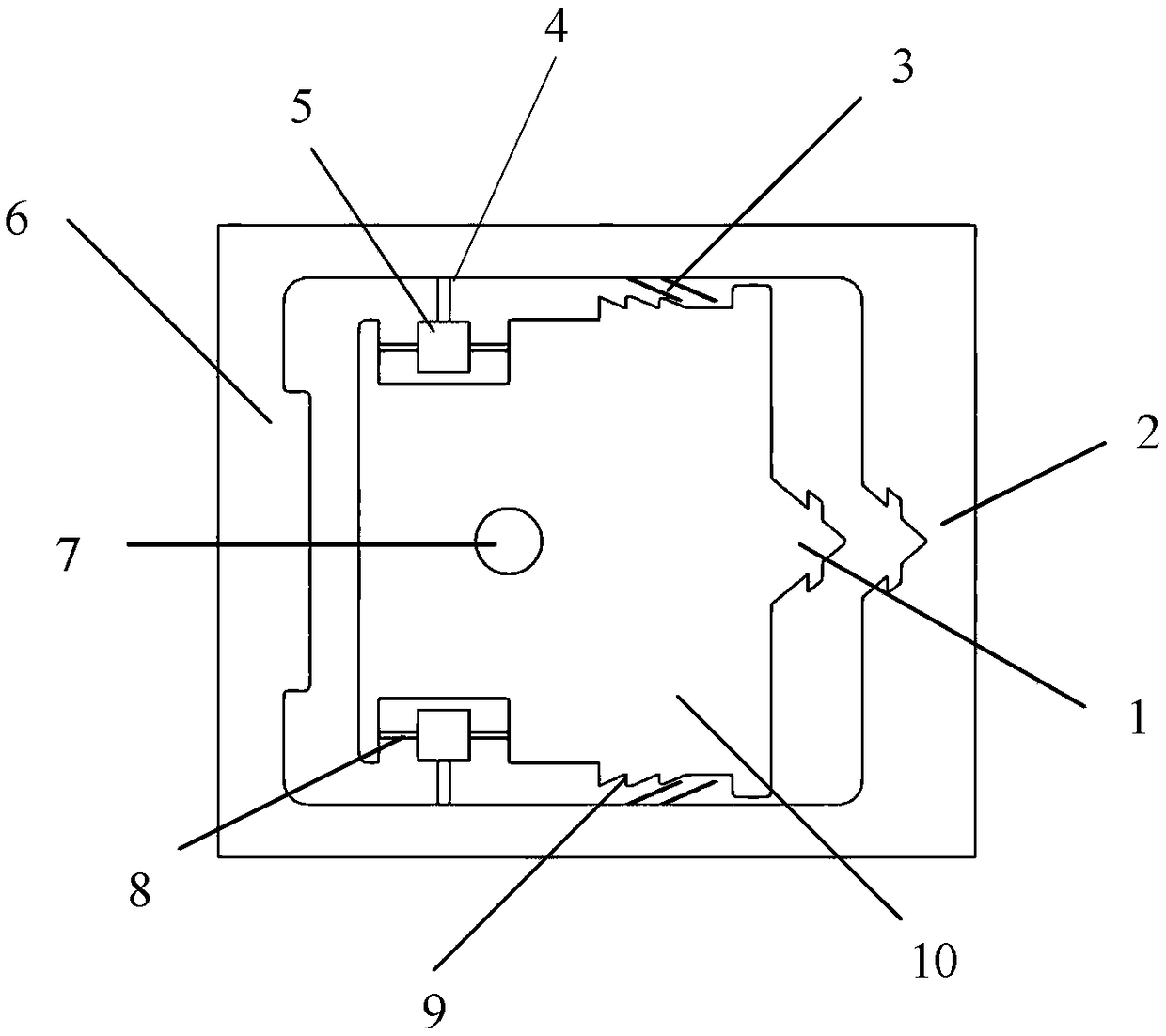

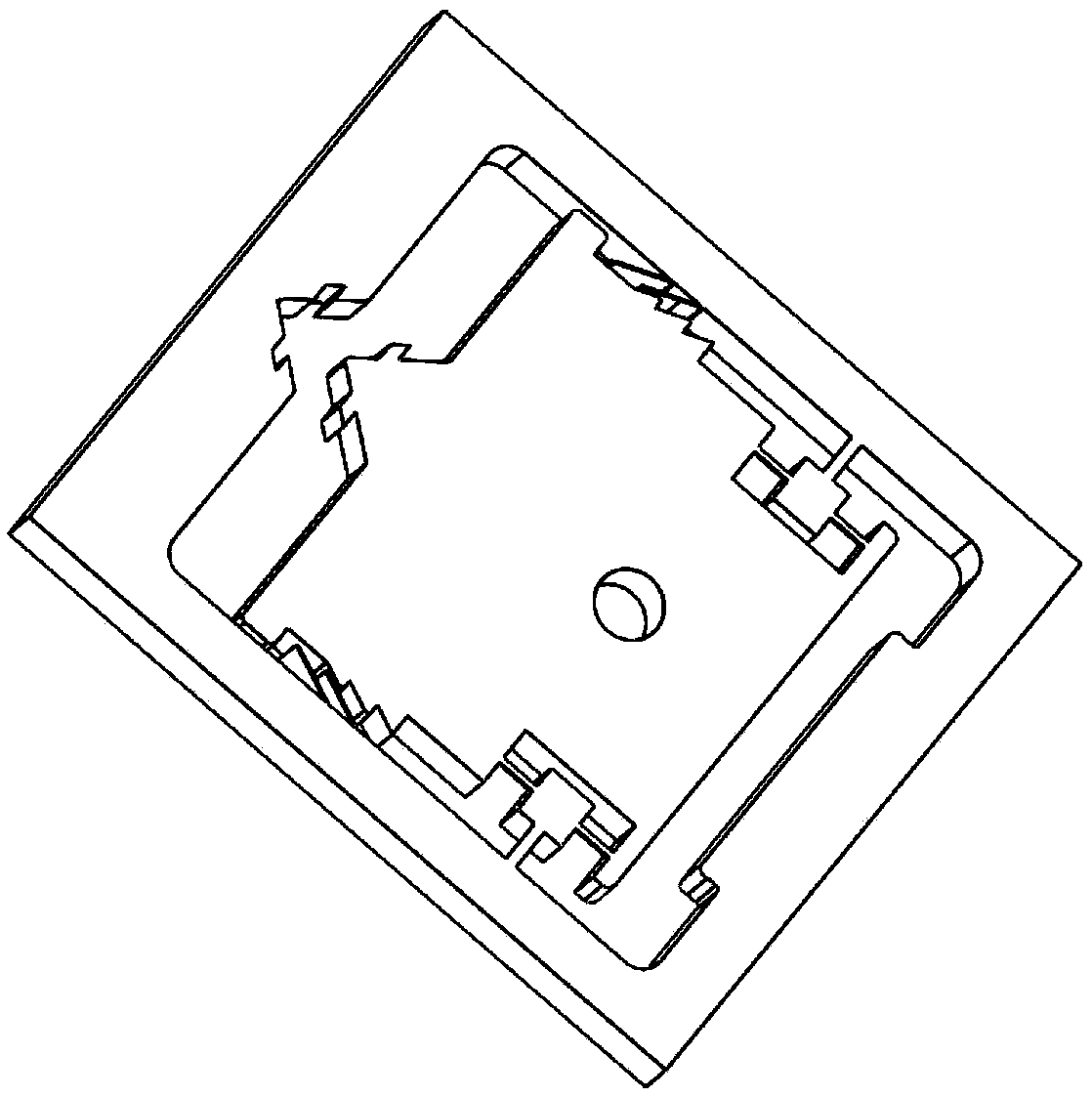

[0038] Such as figure 1 As shown, the MEMS safety system integrated device applied to small-caliber bullets in this embodiment includes: safety system double-ended fixed support limit frame 6, flameproof slider 10, flameproof slider limit pin 1, flameproof slider Block limit groove 2, flameproof slider anti-buffer limit groove 9, flameproof slider anti-buffer limit comb teeth 3, threshold judging mass 5, rear seat overload threshold judging mechanism 8, centrifugal overload threshold judging mechanism 4 and Explosion transmission hole 7; wherein, the safety system double-end fixed support limit frame 6 is an internal hollow support frame; the explosion-proof slider 10 is located in the safety system double-end fixed support limit frame 6, and the outer The edge is smaller than the inner edge of the double-end fixed support limit frame 6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com