Sealing test device and sealing test method for isolation valve of mechanical penetration piece of safety shell of nuclear power plant

A nuclear power plant containment and sealing test technology, applied in the field of nuclear safety, can solve the problems of low safety and complicated operation, achieve precise diversion, protection without excessive loss, and reduce the cost of testing equipment and human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

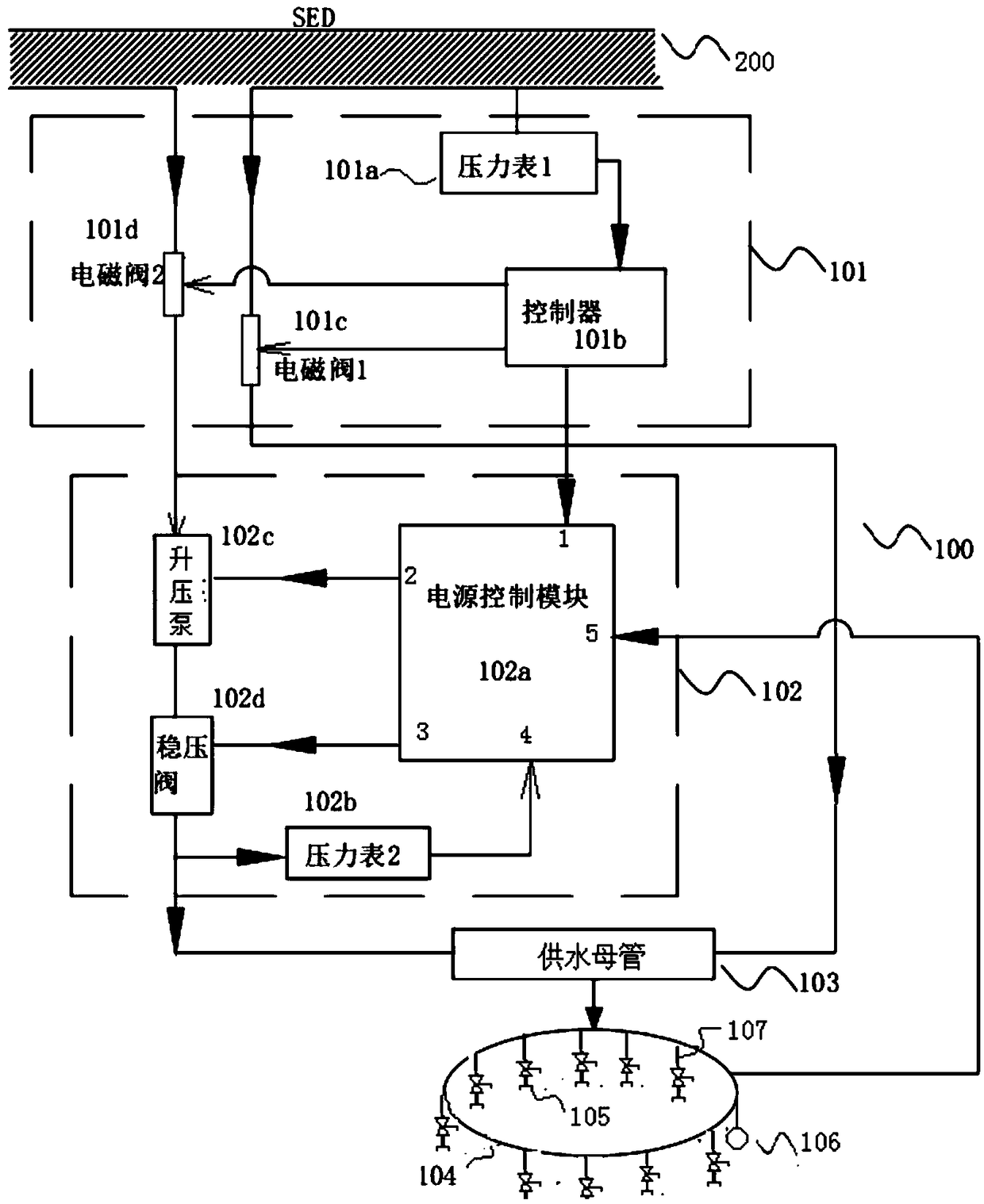

[0058] In the first embodiment, the selection module can be used to controlly select different delivery paths, and different paths can be selected according to the pressure of the water source, which provides a more reliable water pressure guarantee, and the corresponding water source does not need to go through the water supply adjustment module 102. Directly in the ring pipe module, saving time and cost.

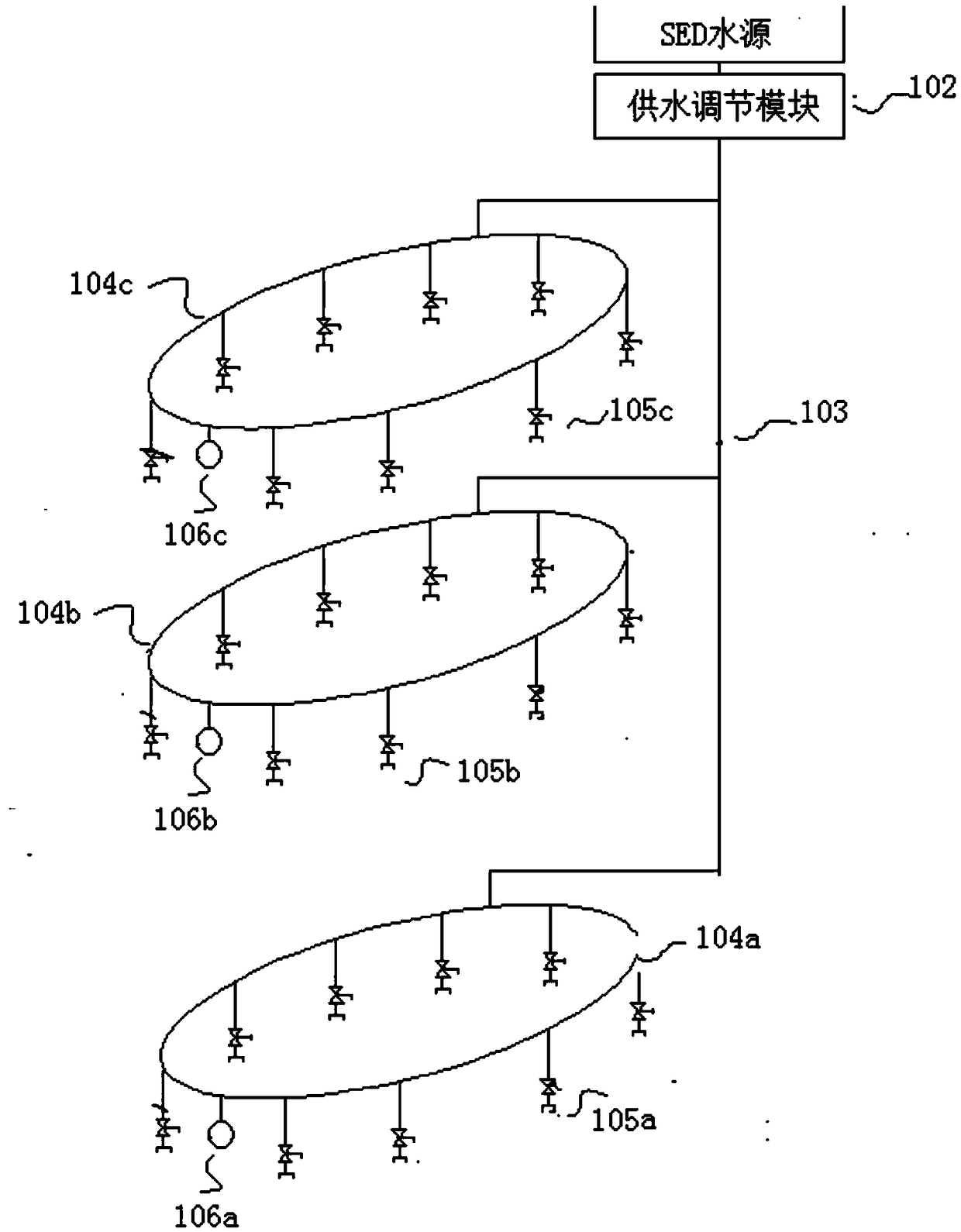

[0059] See attached figure 2 , with figure 2 It is the second embodiment of the present invention. The difference between the second embodiment and the first embodiment is that the SED water source directly enters the water supply regulation module 102 without judgment, and the treatment and pressure of the water source are all realized in the water supply regulation module 102 . Wherein, it includes a SED water source, a water supply regulation module 102, a water supply main pipe 103, and a test system composed of a multi-layer ring pipe module 104. The selection modu...

Embodiment 3

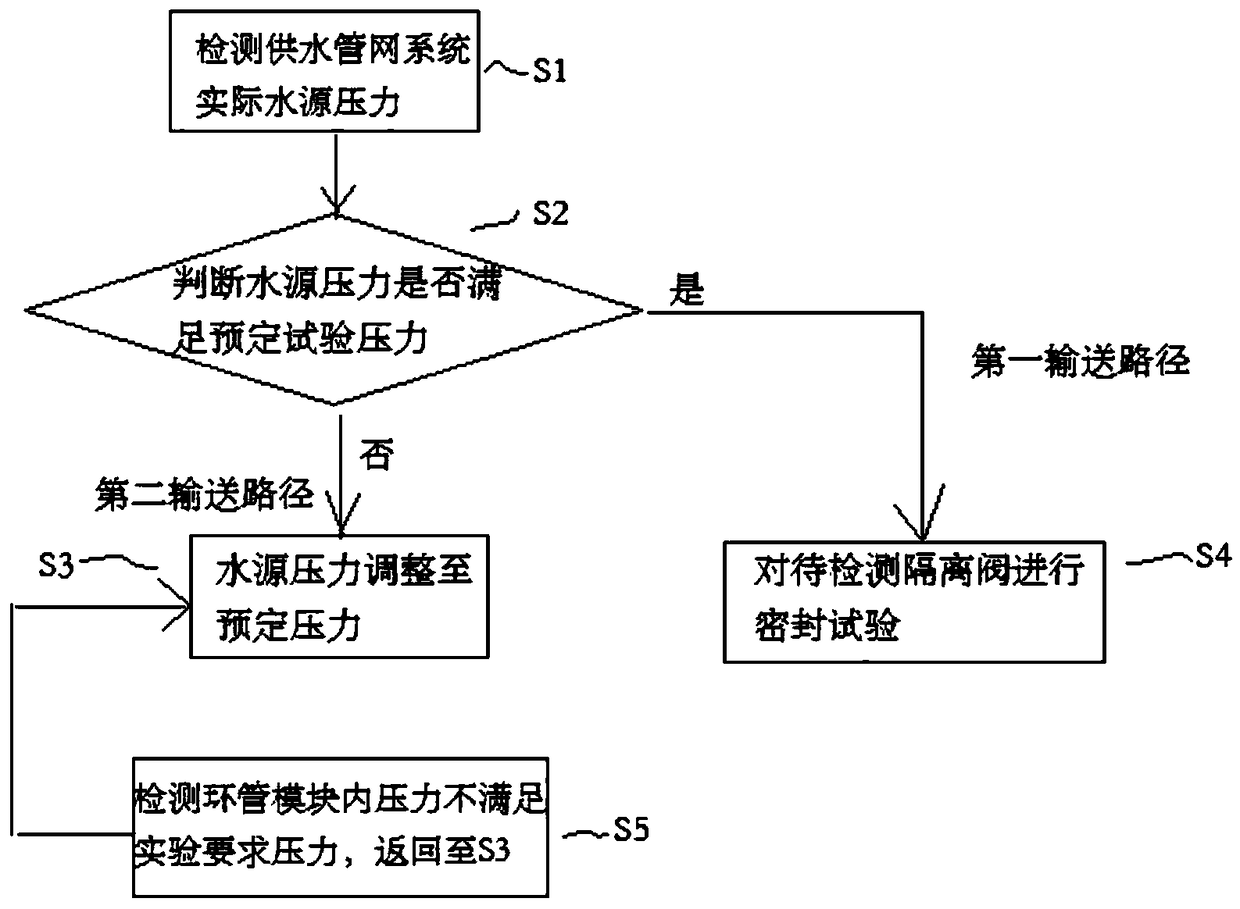

[0065] The implementation of the present invention provides a sealing test method for the isolation valve of the mechanical penetration part of the nuclear power plant containment, which is used to provide the isolation valve with a predetermined pressure of water or gas through the test valve, see image 3 , the method includes:

[0066] S1. Real-time detection of the actual water source pressure of the water supply pipe network system of the SED nuclear island plant;

[0067] S2. Judging whether the predetermined test pressure requirement is met according to the detected actual water source pressure, if the predetermined test pressure requirement is met, switch to the first delivery path, otherwise switch to the second delivery path for pressure adjustment;

[0068] S3. The water supply adjustment module adjusts the pressure that does not meet the test requirements to a predetermined pressure that meets the requirements;

[0069] S4. Select a suitable water source interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com