A Gearbox Fault Diagnosis Method Based on Infrared Thermal Imaging

A technology of infrared thermal imaging and fault diagnosis, which is applied in the testing of machine gear/transmission mechanism, testing of mechanical parts, testing of machine/structural parts, etc. It can solve problems that are difficult to be widely applied, and achieve high recognition rate and intuitive recognition rate Reliable, large detection area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

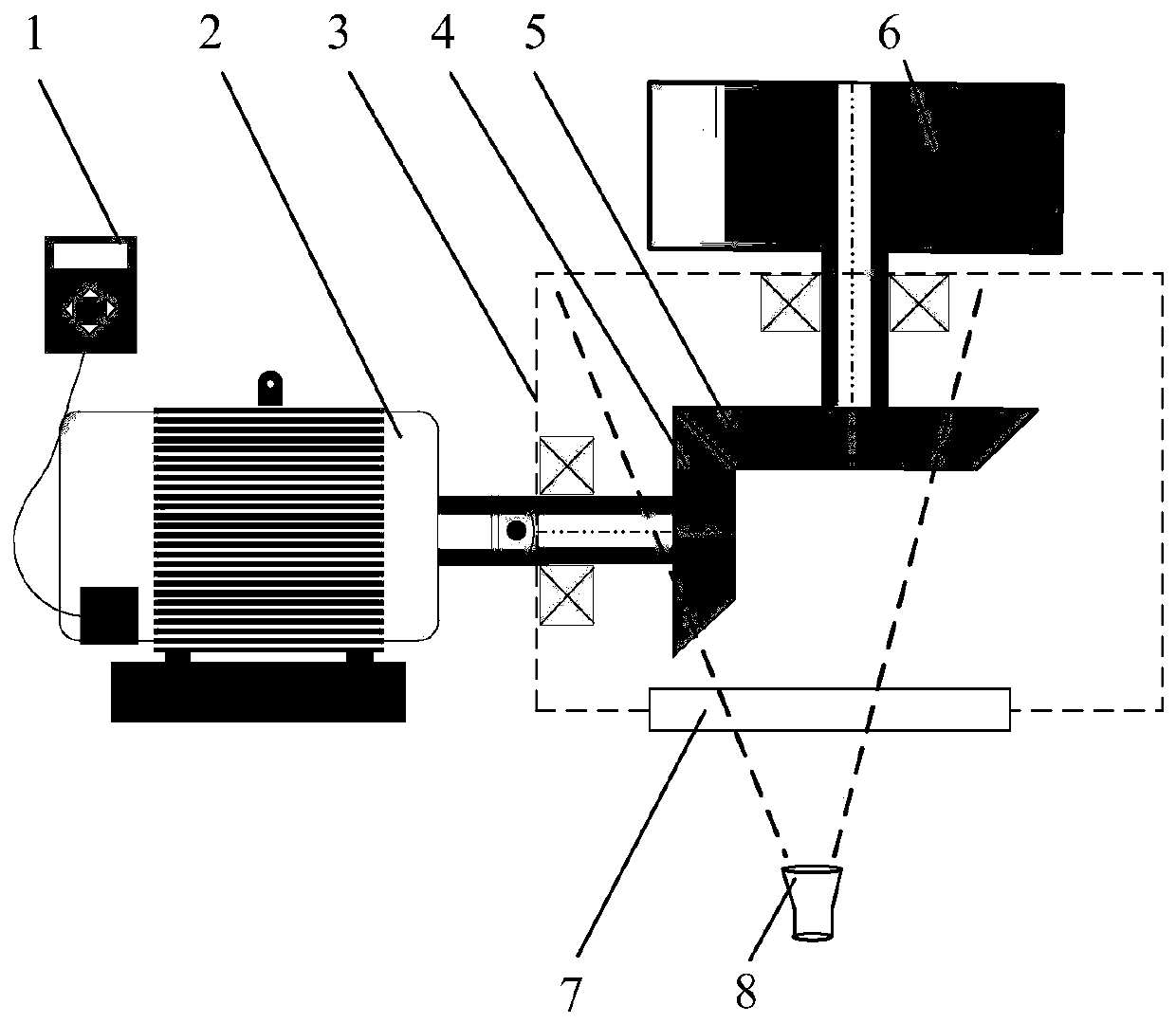

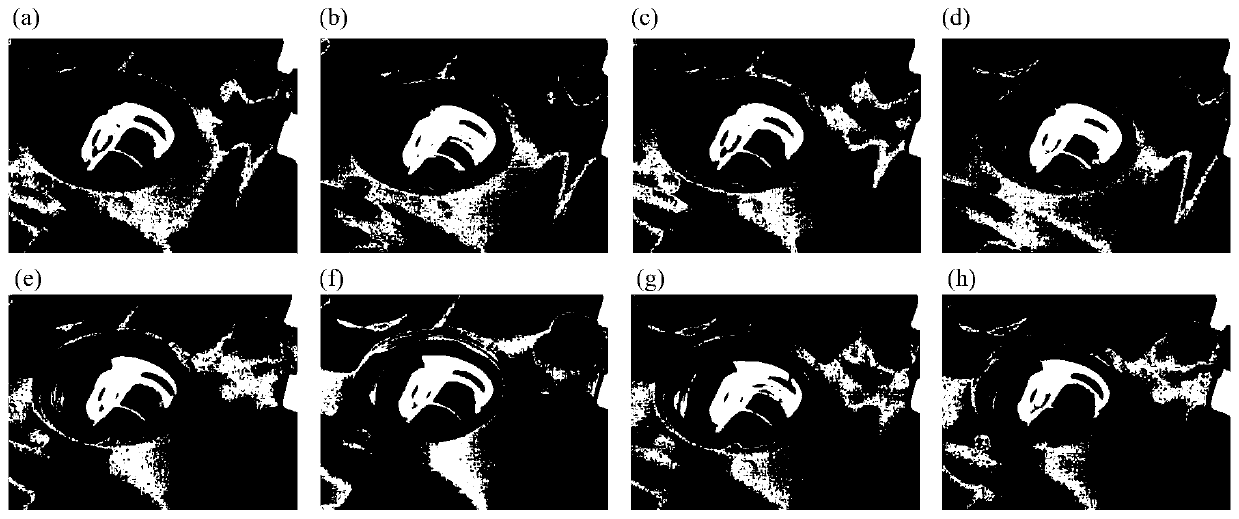

[0045] see Figure 1-Figure 4 , the specific method steps are described as follows:

[0046] 1. Collect infrared heat map

[0047] Step 1: Install the gear failure test piece and debug the gearbox system;

[0048] Step 2: initialize the temperature of the mechanical failure simulation test bench to room temperature (18.9° C. in the present invention);

[0049]Step 3: Let the experimental platform preheat at a speed of 3000rpm, and observe the highest temperature of the IRT map (near the gear mesh) through the infrared thermal imager;

[0050] Step 4: When the highest temperature reaches a given temperature (58°C in this test), collect infrared images;

[0051] Step 5: Cool down the mechanical failure simulation test bench to room temperature;

[0052] Step 6: Select another gear fault type and repeat the above steps to collect the IRT diagram under the current working condition until the end of the experiment.

[0053] 2. Convolutional neural network

[0054] CNN is a fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com