Ultra-low cycle fatigue test device and plastic deformation collection method for round steel pipe

A technology of fatigue test and plastic deformation, which is applied in the direction of measuring device, strength characteristics, and application of repeated force/pulsation force to test the strength of materials, etc., to achieve good safety and stability, and improve the effect of accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

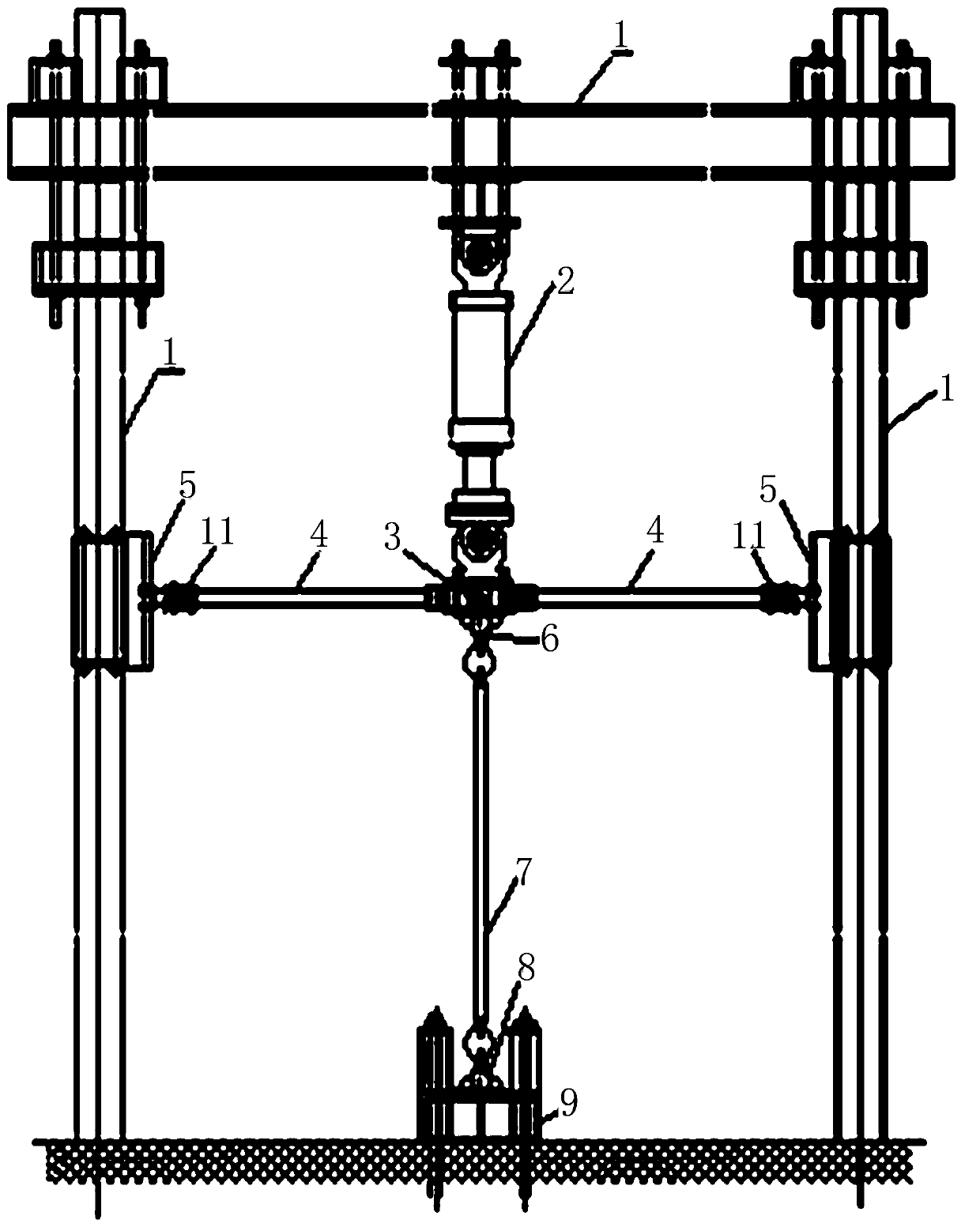

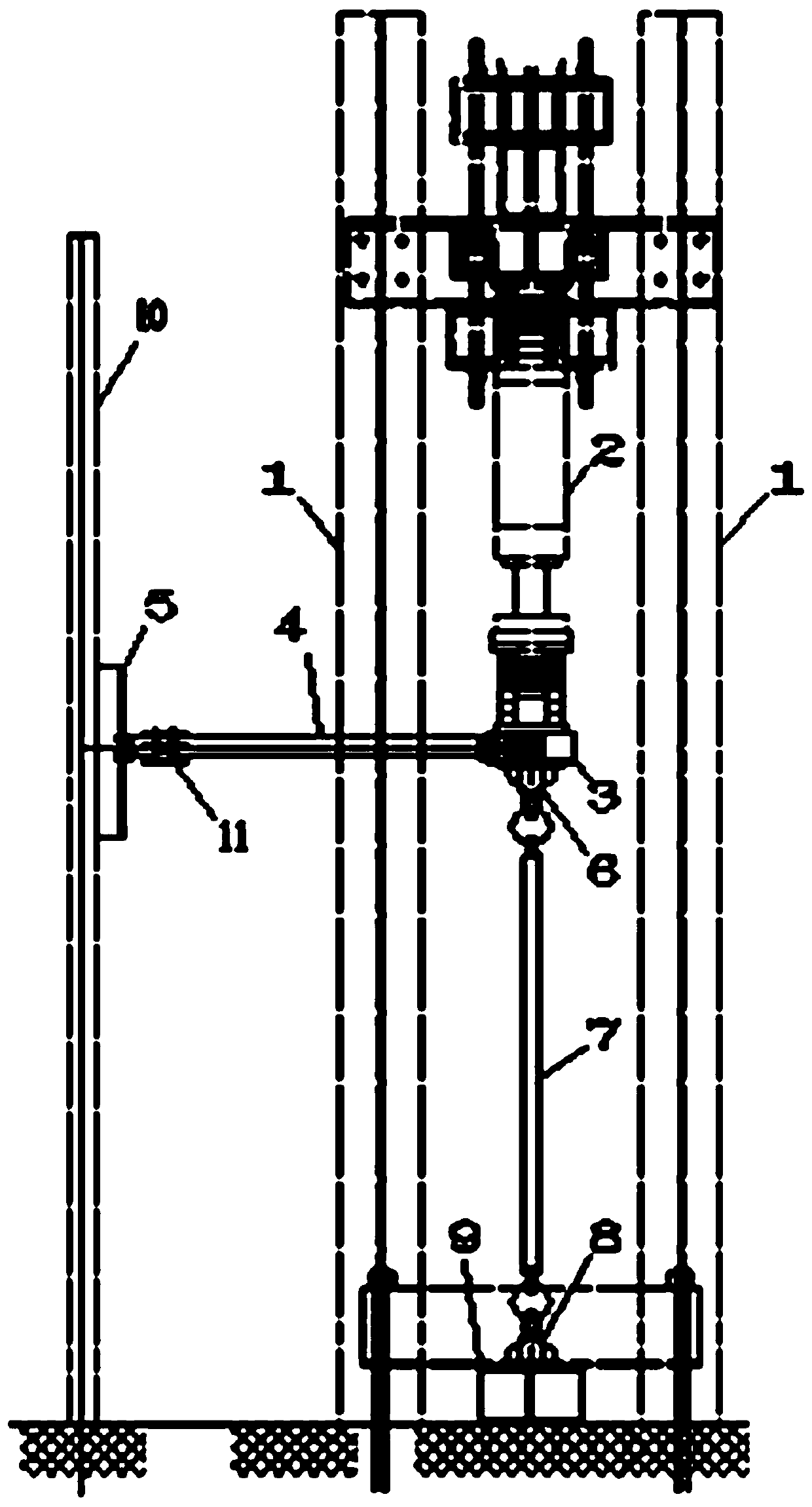

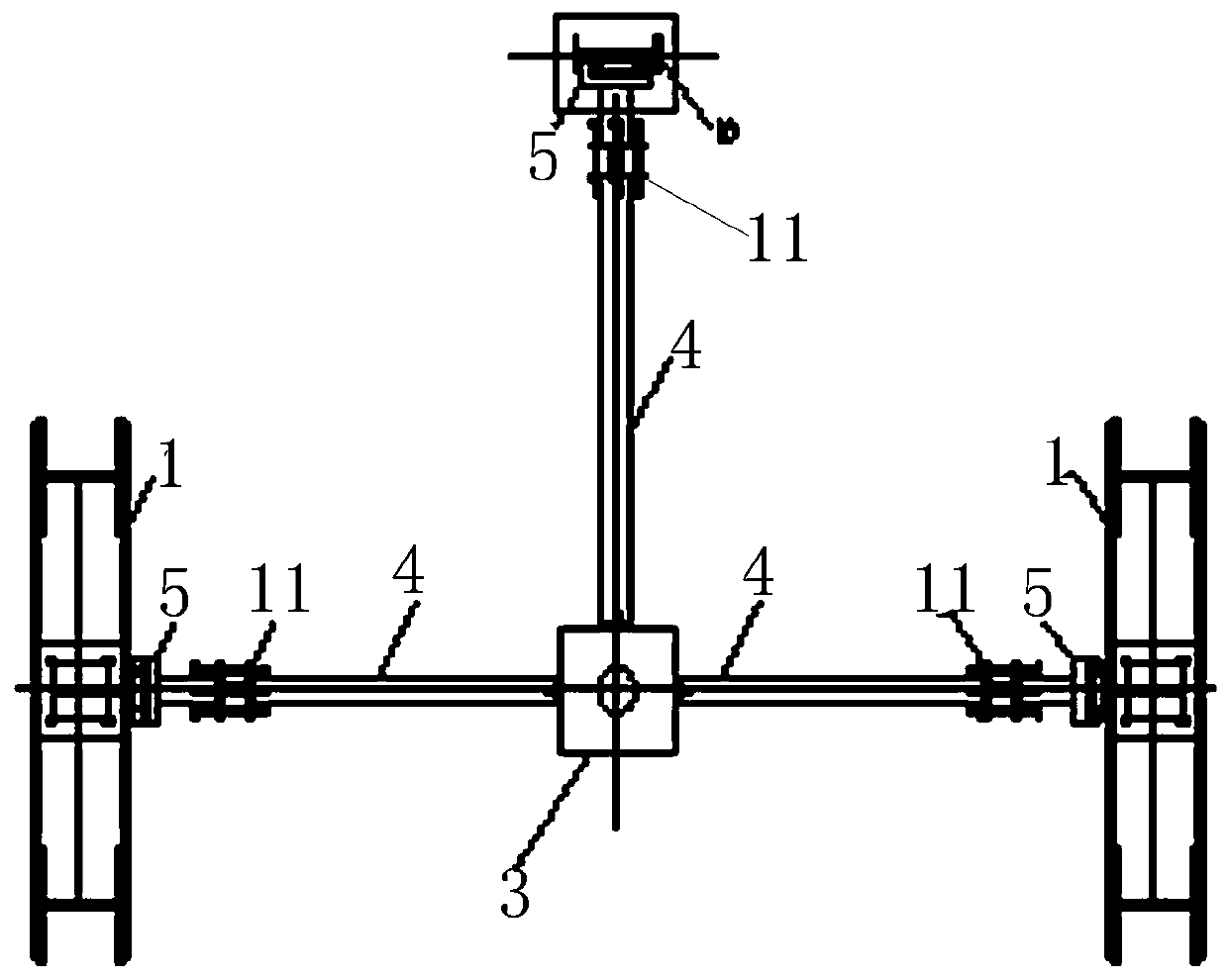

[0037] The present invention will be further described below in conjunction with accompanying drawing.

[0038] refer to Figure 1~4 , the round steel pipe of the present invention applies cyclic reciprocating loading test device, the round steel pipe ultra-low cycle fatigue test device comprises: portal reaction force frame 1, actuator 2, loading bracket 10, limit bracket 4, contact beam 3, flange Disc 11, upper support 6, combined test piece 7 of bolt ball and round steel pipe, bottom support 8, anchor bolts and backing plate 9. The base of the actuator is connected to the crossbeam of the portal reaction frame with long rod anchor bolts (also wound and fastened by wire ropes), and the end of the actuator is connected to the connecting beam 3 with high-strength bolts. The left, right and rear of the square connecting beams The three-way connection limit bracket 4, the other end of the limit bracket 4 is welded with a hook 12 to connect with the chute 5 connected to the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com