Mobile phone glass AF membrane surface defect detection device and detection method

A defect detection, film surface technology, applied in the direction of measuring devices, optical testing of defects/defects, material analysis through optical means, etc., can solve the problems of high light transmittance of AF film, achieve low cost, high detection efficiency, and detection The results are accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

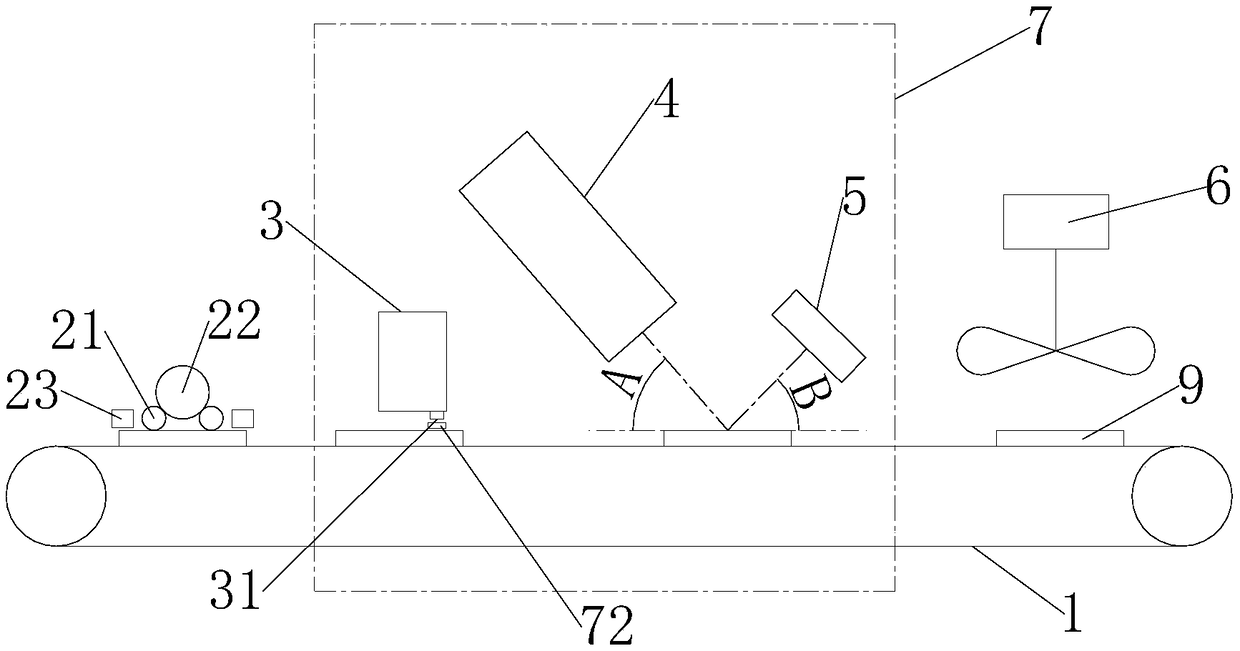

[0043] Such as Figure 1 to Figure 3As shown, a mobile phone glass AF film surface flaw detection device includes a conveyor belt 1, a camera 4, and a light source 5 that are all connected to the detection control system. The glass 9 is placed on the conveyor belt 1, and the camera 4 and light source 5 are located on the conveyor belt. 1, the camera 4 shoots the AF film of the glass under test, and the light source 5 irradiates the AF film of the glass under test; it also includes a spray device 3, which is located on one side of the camera 4, and the spray device 3 is connected with the detection control system, and the spray device 3 The nozzle 31 is located above the tested glass AF film, and the nozzle 31 sprays water mist evenly on the surface of the glass AF film, and the surface of the glass AF film is uniformly covered with a layer of tiny mist, and the camera 4 shoots the glass AF before the mist disappears. the surface of the membrane.

[0044] The nozzle 31 is prov...

Embodiment 2

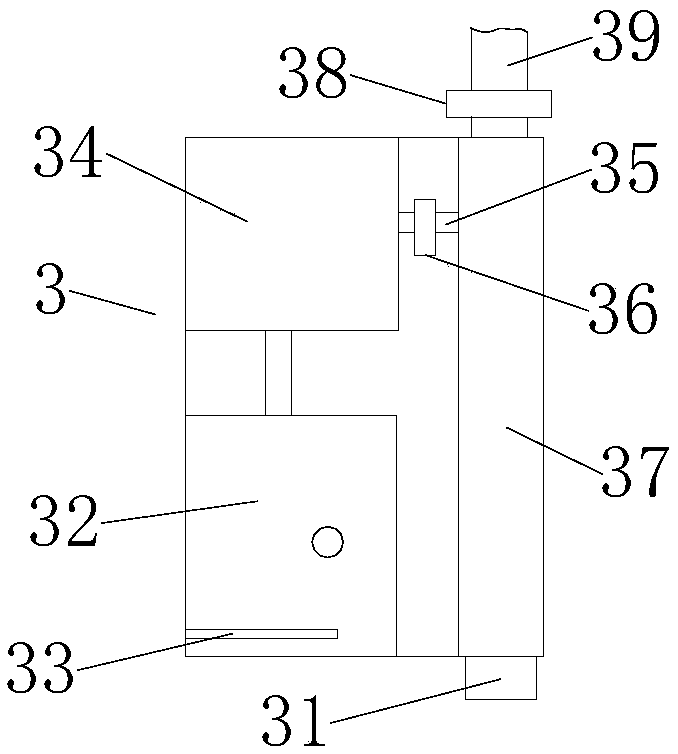

[0062] On the basis of the above embodiments, the steam generator 32 is connected to the high temperature superheater 34 through the connecting pipe, and the high temperature superheater 34 is connected to the mixing box 37 through the gas outlet pipe 35 .

[0063] The high-temperature superheater 34 further heats the steam, and the steam forms superheated saturated steam. The superheated saturated steam is not easy to condense into water, so that when the steam is ejected from the nozzle 31, water droplets can be formed uniformly, so as to avoid rapid cooling of the steam to form larger water droplets. At the same time, it is possible to avoid the formation of condensed water when mixing with air inside the mixing box 37 . The high-temperature superheater 34 is an existing mature product. The high-temperature superheater 34 is electrically heated to maintain a high temperature state. The steam is further heated through the high-temperature superheater 34, and the steam becomes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com