Camera lens, camera module and terminal

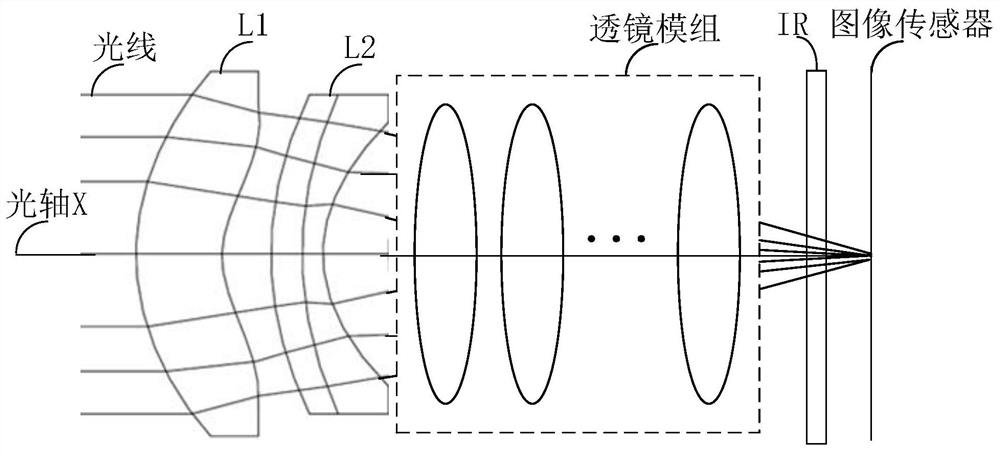

A technology of camera lens and camera module, which is applied to lenses, image communication, instruments, etc., can solve the problems of increasing TTL parameters, difficulty in further increasing the total thickness and area of the camera lens, and increasing the size of the image sensor, so as to reduce chromatic aberration. , to meet the effect of miniaturization and small TTL

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

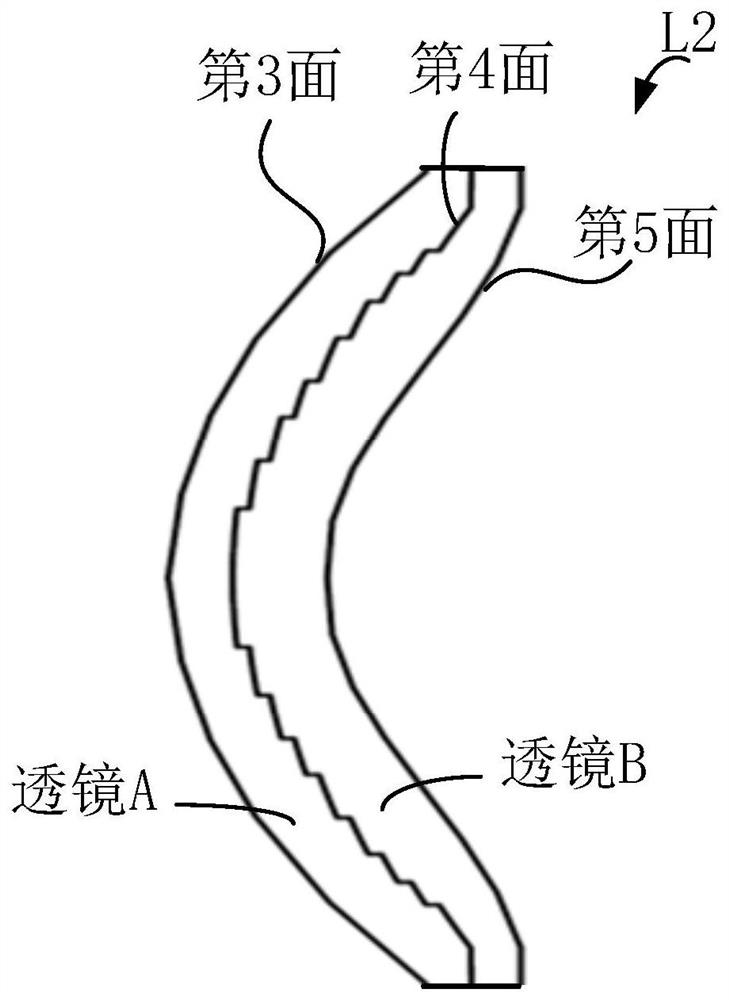

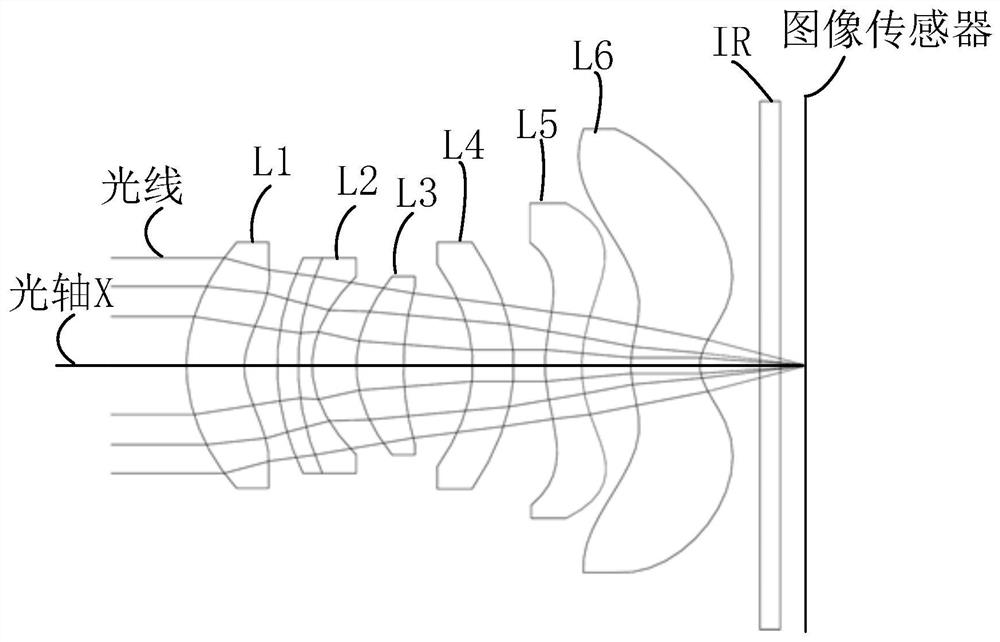

[0056] Embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

[0057]The terms used in the embodiments of the present invention are only used to explain specific examples of the present invention, and are not intended to limit the present invention. First, the concept of aberration involved in the embodiment of the present invention is explained. Aberration (aberration) refers to the inconsistency between the results obtained by non-paraxial ray tracing and the results obtained by paraxial ray tracing in the optical system, and the deviation from the ideal state of Gaussian optics (first-order approximation theory or paraxial ray) . Aberration is divided into two categories: chromatic aberration (chromatic aberration, or chromatic aberration) and monochromatic aberration (monochromatic aberration). Chromatic aberration is due to the refractive index of the lens material is a function of wavele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com