Method for calculating lifting height of scissor-type high-altitude work platform

An aerial work platform and height calculation technology, applied in the field of aerial work platforms, can solve the problems of inaccuracy, sensor measurement error, large error, etc., and achieve the effect of low computational complexity and good real-time performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

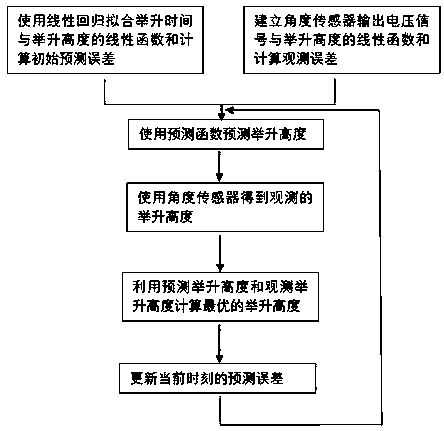

[0040] A method for calculating the lifting height of a scissor type aerial work platform of the present invention comprises the following steps:

[0041] (1) Use the linear regression method to fit the linear relationship between the single lifting time and the lifting height of the scissor aerial work platform, and calculate the prediction error;

[0042] 1.1 Count the longest lifting time of this type of scissor aerial work platform, denoted as max(t);

[0043] 1.2 The shortest lifting time is 0, divide the interval [0,max(t)] into m segments, take n sample points in each segment, a total of m*n sample points, and count the different lifting time t and the corresponding The lifting height value h, denoted as (t i , h j );

[0044] 1.3 Divide the values of m*n sample points into training set and test set, and use linear programming method to train the linear relationship between single lifting time and lifting height. The linear equation is: h(t)=a *t+b, where a and b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com