Profile support, battery pack and vehicle

A technology for battery packs and profiles, applied to battery pack parts, circuits, electrical components, etc., can solve problems that affect the dimensional accuracy of mounting brackets and reduce mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

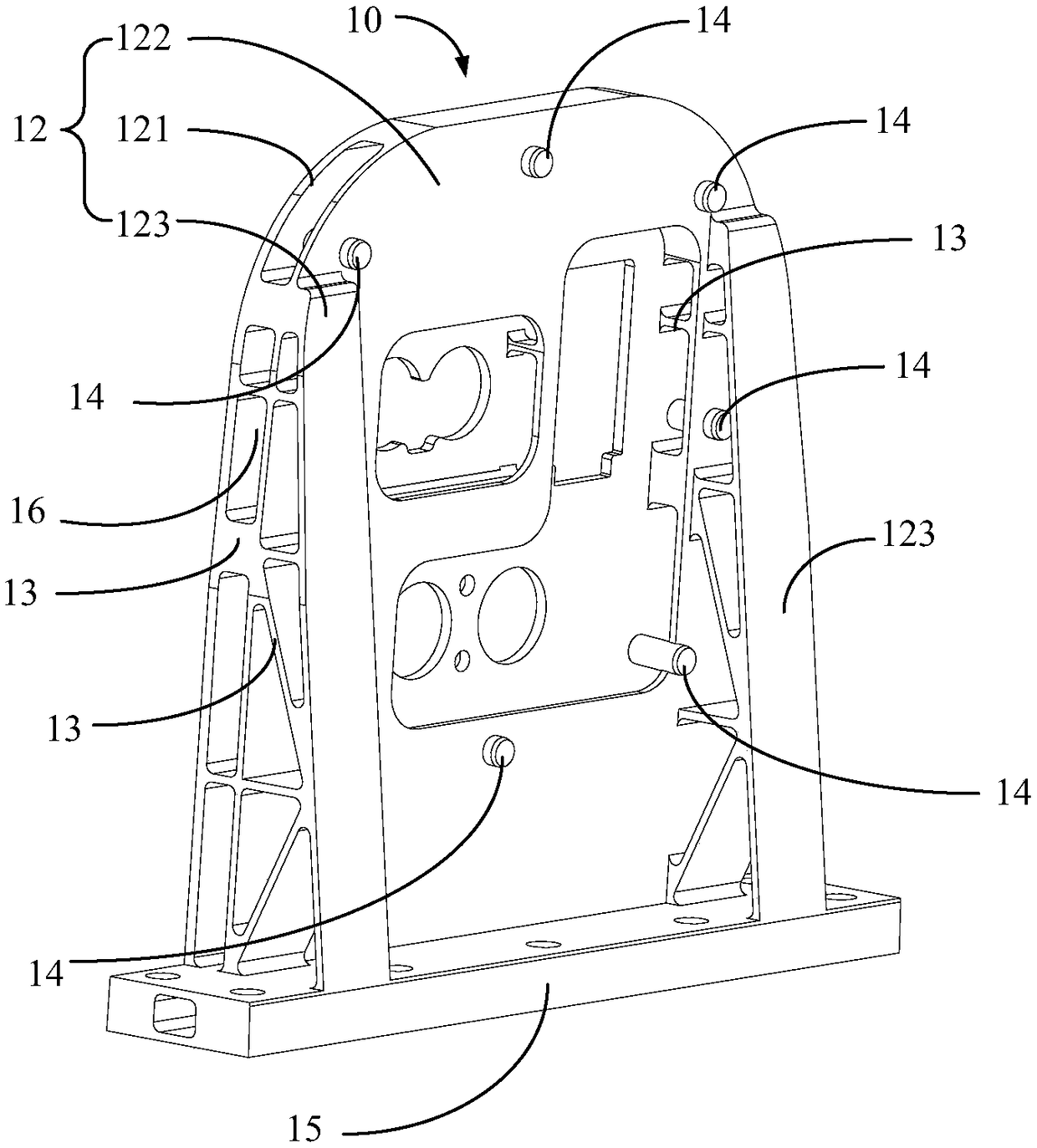

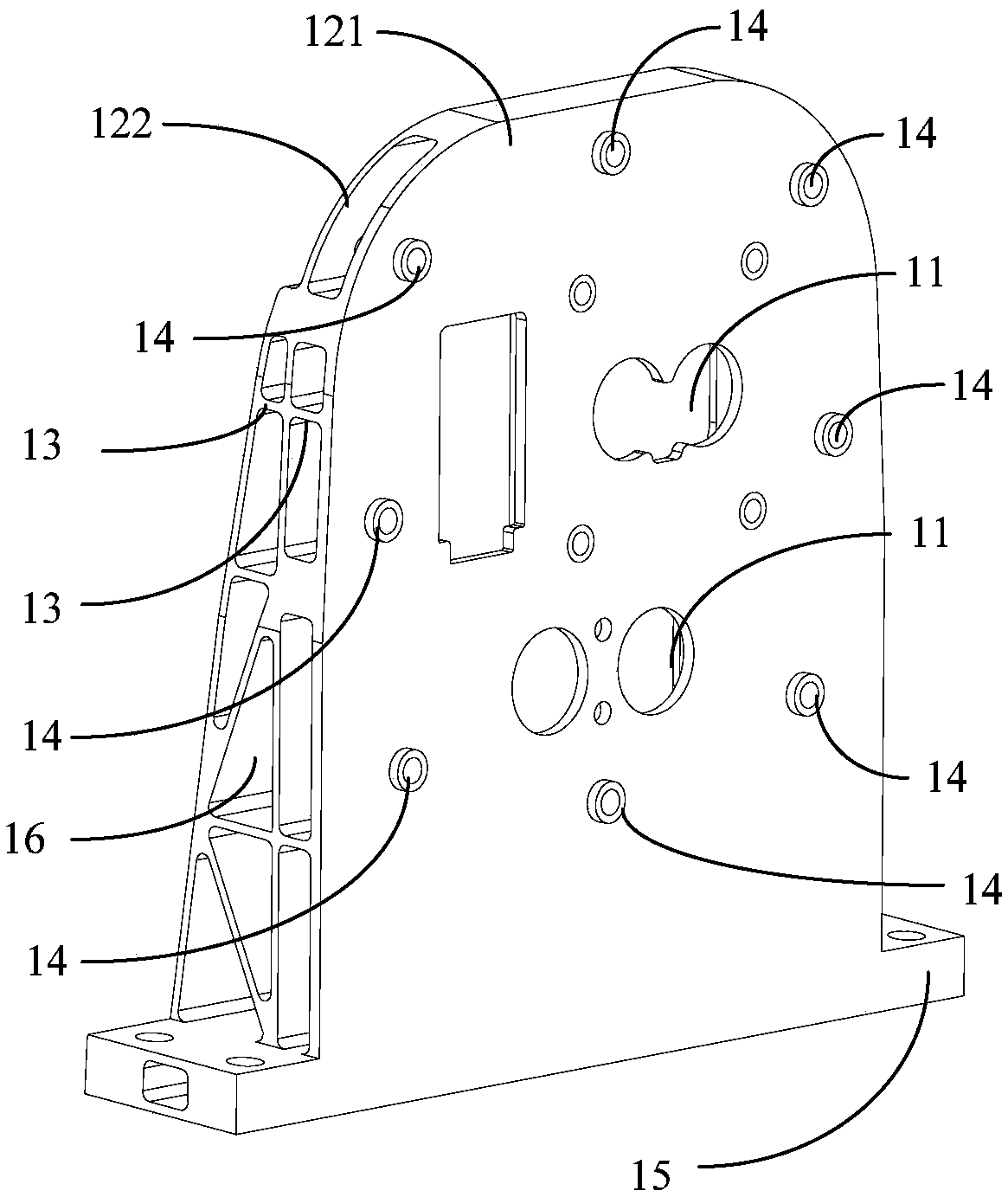

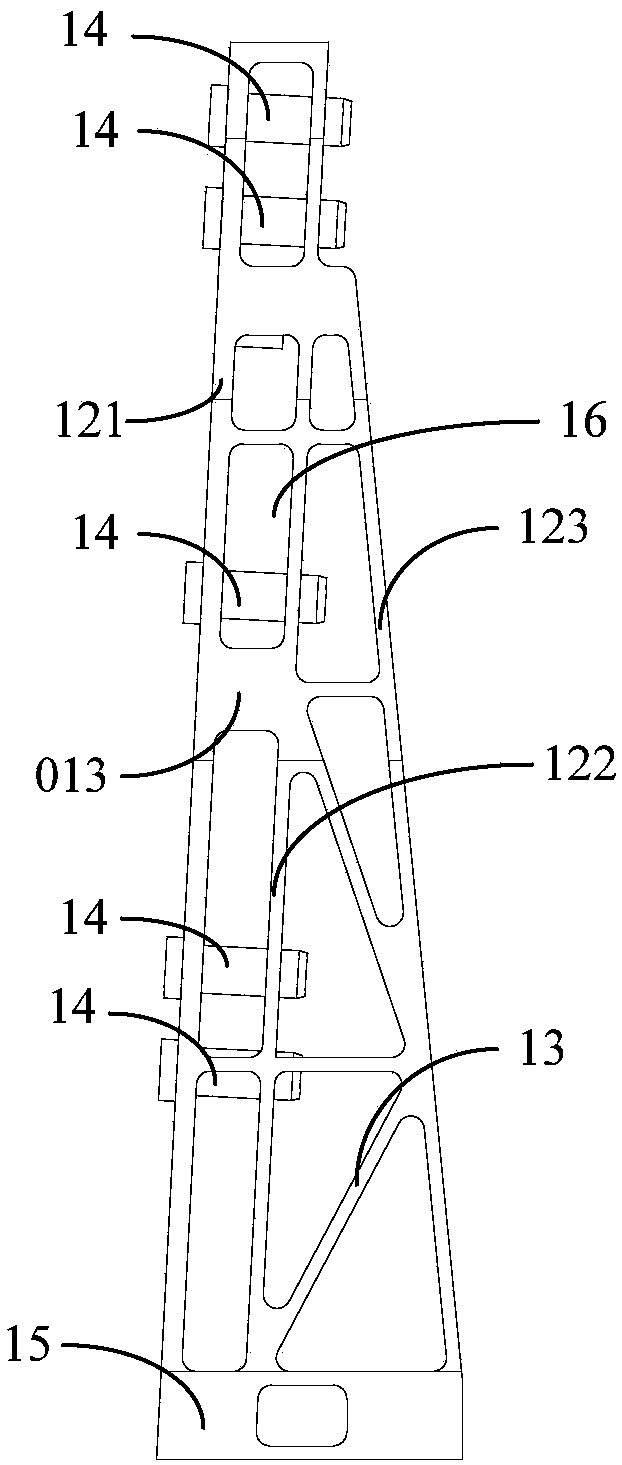

[0082] like Figure 1 to Figure 9 As shown, the specific embodiment of the present invention provides a battery pack, which mainly includes a battery box and a profile bracket 10 detachably connected to the battery box.

[0083] Specifically, a protrusion 2112 is provided on the case cover 211 of the battery case, and an opening 2111 is provided on the side wall of the protrusion 2112 . The profile support 10 includes a first plate 121, a second plate 122 and a third plate 123 arranged in sequence, and the base 15 of the profile support 10 is simultaneously with the first plate 121, the second plate 122 and the third plate 123 Fixedly connected, at the same time the side of the first plate body 121 and the second plate body 122 away from the base 15 is also connected. The first plate body 121 and the second plate body 122 define a cavity 16, and the cavity 16 is provided with reinforcing ribs 13 respectively abutting against the first plate body 121 and the second plate body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com