A terminal structure for electric vehicle power battery pack

A technology for power batteries and electric vehicles, applied in small-sized batteries/batteries, battery pack components, structural parts, etc., can solve problems such as insignificant effects, damage to terminals, pollution of terminals, etc., to improve reliability. and stability, flexible and convenient use, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

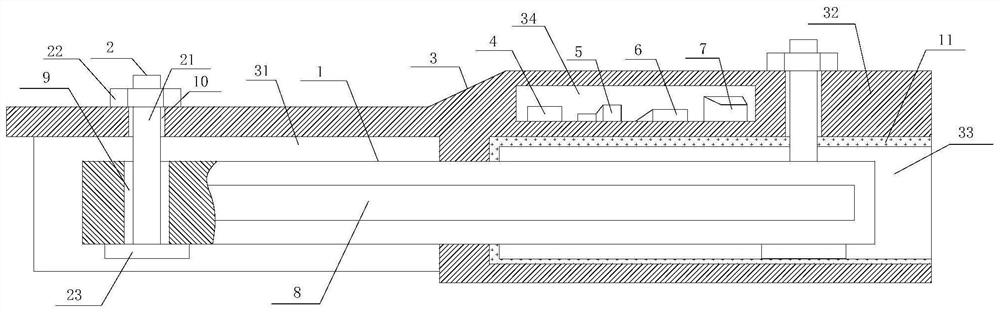

[0014] Such as figure 1 The described wiring terminal structure for a power battery pack of an electric vehicle comprises a wiring electrode 1, a wiring bolt 2, an insulating protective cover 3, a temperature sensor 4, a current detection device 5, a voltage detection device 6 and a control circuit 7, and the wiring electrode 1 It is a plate-shaped structure with a rectangular cross section, and at least two chute 8 are provided on its side surface, the chute 8 is symmetrically distributed on both sides of the wiring electrode 1 with the axis of the wiring electrode 1, and the chute 8 is parallel to the axis of the wiring electrode 1, The wiring electrode 1 is provided with at least two wiring screw holes 9, the wiring screw holes 9 are symmetrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com