Production method of non-oil-fried milk-flavor crispy strawberries

A production method, non-fried technology, applied in confectionery, confectionery industry, food science, etc., can solve the problems of difficult storage of strawberries, low protein content, and reduced nutritional value, and achieve good expansion, high vitamins and protein , the effect of increasing protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

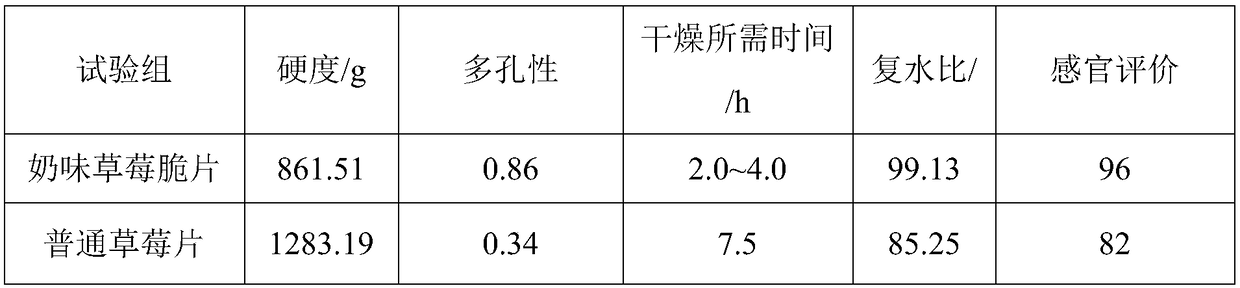

Examples

Embodiment 1

[0024] A method for making non-fried milk-flavored strawberry crisp, the steps are as follows:

[0025] (1) After picking and cleaning the strawberries, cut them in half for 6mm, and make holes on the surface with a diameter of 1mm and a density of 1 piece / cm 2 ).

[0026] (2) Put it into a 15% by mass sucrose solution at 80°C and blanch for 4 seconds, and the ratio of solid to liquid is 1:2.

[0027] (3) Place it in a 25°C sucrose solution with a mass percentage of 40% and immerse for 3 hours, and the ratio of solid to liquid is 1:1.

[0028] (4) After taking out and draining the surface liquid, place it in a vacuum microwave drying unit for pulse-type puffing drying. Drying conditions: material load is 0.8kg, vacuum degree is 0.07Mpa, material temperature is 25°C, and microwave power of 0.5KW is used for drying After 3 minutes, use 0KW microwave power to dry for 2 minutes, then open the inlet valve, let the gas flow in until the vacuum degree is 0Mpa, stay for 10-30S, and ...

Embodiment 2

[0033] A method for making non-fried milk-flavored strawberry crisp, the steps are as follows:

[0034] (1) After the strawberries are selected and cleaned, they are cut in half. After the thickness is 15mm, holes are made on the surface with a diameter of 3mm and a density of 1 piece / cm 2 .

[0035] (2) Put it into a 100°C sucrose solution with a mass percentage of 35% for blanching for 10 seconds, and the ratio of solid to liquid is 1:4.

[0036] (3) Place it in a 40°C sucrose solution with a mass percentage of 60% and immerse for 3 hours, and the ratio of solid to liquid is 1:4.

[0037] (4) After taking out and draining the surface liquid, place it in a vacuum microwave drying unit for pulse-type puffing and drying. Drying conditions: material load is 2.5kg, vacuum degree is 0.085Mpa, material temperature is 50°C, and dried with 2KW microwave power for 8min Then use 0.5KW microwave power to dry for 7 minutes, and repeat the operation 4 times until the sample is dried to ...

Embodiment 3

[0042] A method for making non-fried milk-flavored strawberry crisp, the steps are as follows:

[0043] (1) After picking and cleaning the strawberries, cut them in half. After the thickness is 10mm, make holes on the surface with a diameter of 2mm and a density of 1 piece / cm 2 .

[0044] (2) Put it into a 90°C sucrose solution with a mass percentage of 25% and blanch for 8S (the ratio of solid to liquid is 1:3).

[0045] (3) Place the sucrose solution with a mass percentage of 50% at 30° C. for 3 h (the ratio of solid to liquid is 1:3).

[0046](4) After taking out and draining the surface liquid, place it in a vacuum microwave drying unit for pulse-type puffing drying. Drying conditions: material load is 2kg, vacuum degree is 0.075Mpa, material temperature is 40°C, and after drying with 1KW microwave power for 5min Then use 0.25KW microwave power to dry for 5 minutes (repeat the operation 3 times until the sample is dried to a moisture content of 55% on a wet basis).

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com