Rock crushing equipment for water conservancy engineering

A water conservancy project and gravel technology, which is applied in the direction of grain processing, can solve the problems of reducing the work efficiency of workers, increasing the labor intensity of maintenance workers, and the difficulty of installing, fixing, disassembling and replacing flywheels, etc., so as to achieve convenient installation, fixing and disassembly, and convenient operation and use , Improve the effect of working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

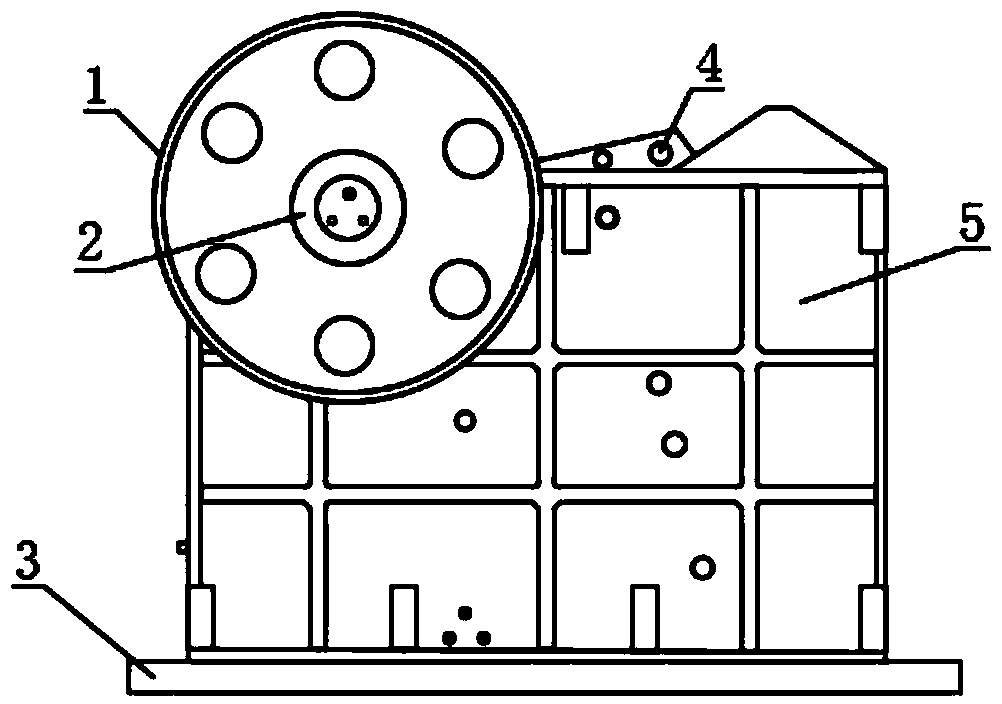

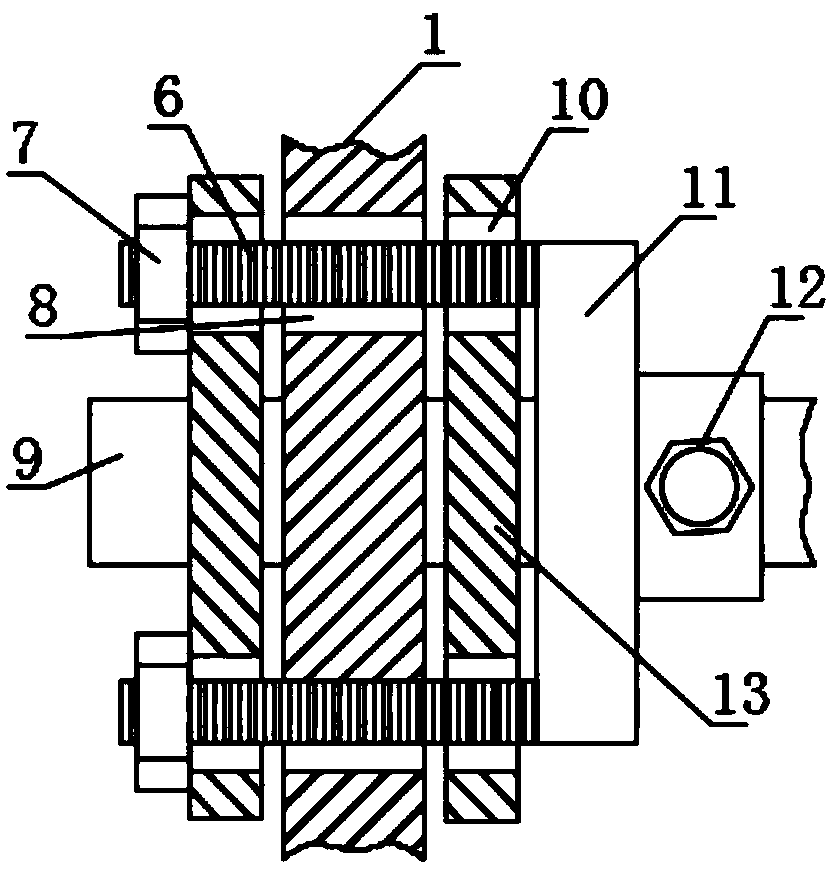

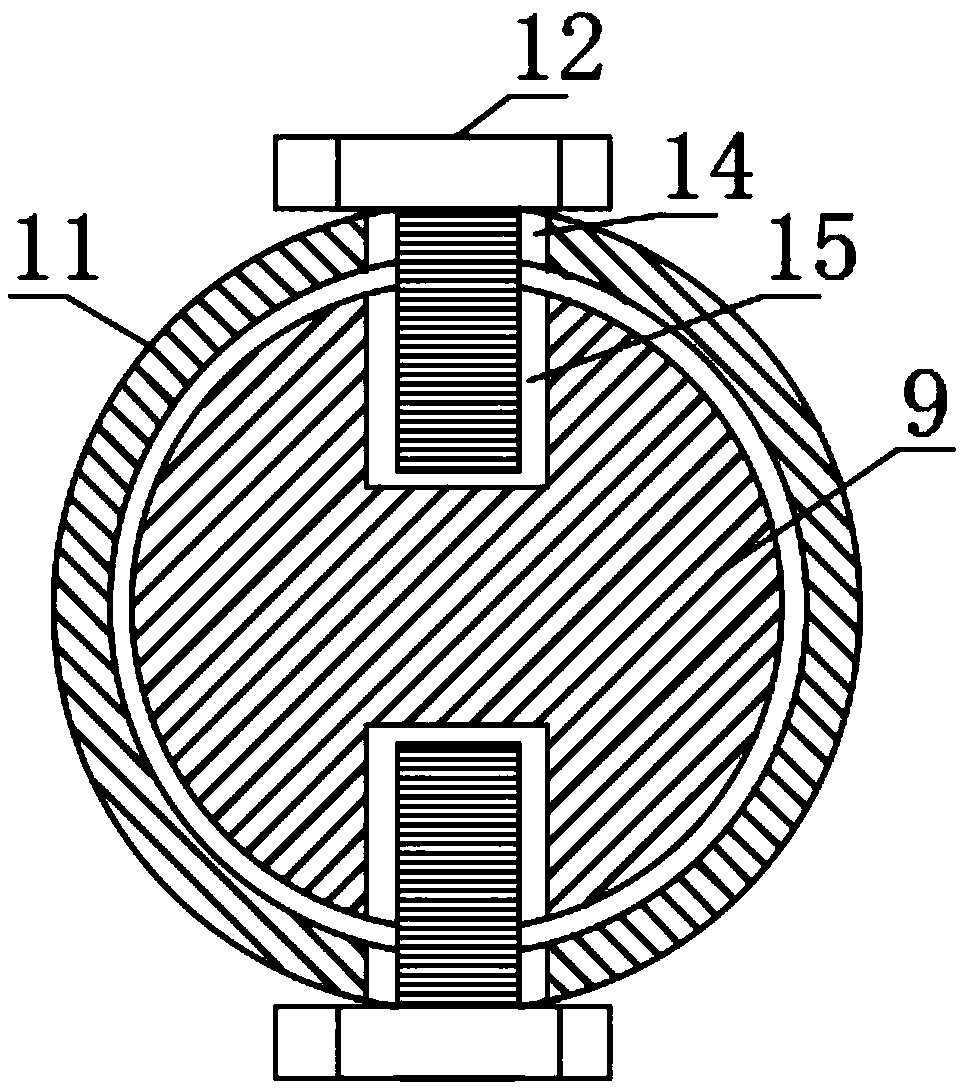

[0021] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution: a stone crushing equipment for water conservancy engineering, comprising a flywheel 1, a stone crushing equipment main body 5, an eccentric shaft 9 and a support mechanism provided at the bottom of the stone crushing equipment main body 5, and the surface of the flywheel 1 is provided with a fixed mechanism, the fixing mechanism includes a fixed rod 6, a hexagonal head nut 7, a connecting hole 8, a fixing hole 10, a fixed plate 11, a hexagonal head bolt 12, a fastening washer 13, a threaded hole 14 and a threaded groove 15, and the flywheel 1 is symmetrically installed and fixed on The surface of the eccentric shaft 9 is located on both sides of the main body 5 of the stone crushing equipment. The eccentric shaft 9 is installed and fixed inside the main body 5 of the stone crushing equipment. The connecting holes 8 are symmetrically opened on the surfa...

Embodiment 2

[0027] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution: a stone crushing equipment for water conservancy engineering, comprising a flywheel 1, a stone crushing equipment main body 5, an eccentric shaft 9 and a support mechanism provided at the bottom of the stone crushing equipment main body 5, and the surface of the flywheel 1 is provided with a fixed mechanism, the fixing mechanism includes a fixed rod 6, a hexagonal head nut 7, a connecting hole 8, a fixing hole 10, a fixed plate 11, a hexagonal head bolt 12, a fastening washer 13, a threaded hole 14 and a threaded groove 15, and the flywheel 1 is symmetrically installed and fixed on The surface of the eccentric shaft 9 is located on both sides of the main body 5 of the stone crushing equipment. The eccentric shaft 9 is installed and fixed inside the main body 5 of the stone crushing equipment. The connecting holes 8 are symmetrically opened on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com