Board polishing device for processing of solid wood furniture

A technology for polishing devices and furniture, which is applied to grinding drive devices, metal processing equipment, grinding/polishing equipment, etc., can solve the problem of wood chips affecting polishing and other problems, and achieve a good polishing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

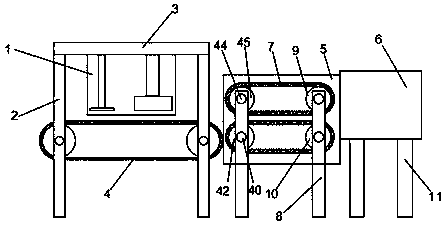

[0026] Embodiment 1: refer to figure 1 , a wood polishing device for solid wood furniture processing, comprising a rough polishing device 1, a first support frame 2, a fine polishing feeding device 5 and a fine polishing device 6, characterized in that: the top of the first support frame 2 is fixedly installed with A fixed plate 3, a conveyor belt 4 is fixedly installed in the middle of the first support frame 2, a rough polishing device 1 is fixedly installed under the fixed plate 3, and the rough polishing device 1 is located above the conveyor belt 4, and the right side of the conveyor belt 4 is set There is a second support frame 8, the fine polishing feeding device 5 is fixedly connected with the second supporting frame 8, the right side of the fine polishing feeding device 5 is fixedly connected with a fine polishing device 6, and the lower end of the fine polishing device 6 is fixed A third support frame 11 is installed.

[0027] When the present invention is in use, t...

Embodiment 2

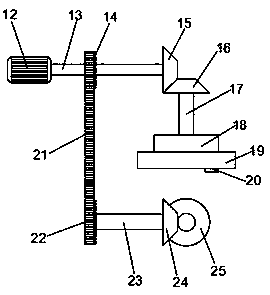

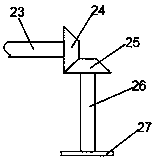

[0028] Embodiment 2: refer to Figure 2-4 , the difference with the basis of Embodiment 1 is that the rough polishing device 1 includes a first motor 12, a connecting plate 19 and a driven sprocket 22, and the right end of the first motor 12 is fixedly connected with a first driving shaft 13, the middle part of the first driving shaft 13 is fixedly equipped with a driving sprocket 14, and the right end of the first driving shaft 13 is fixedly equipped with a first driving bevel gear 15, and the driving sprocket 14 and the driven sprocket 22 pass through The chain 21 is connected by transmission, the right side of the driven sprocket 22 is fixedly connected with a first transmission shaft 23, the right end of the first transmission shaft 23 is fixedly equipped with a second driving bevel gear 24, and the lower end of the second driving bevel gear 24 is A second driven bevel gear 25 is meshingly connected, and a second rotating shaft 26 is fixedly connected to the lower end of t...

Embodiment 3

[0031] Embodiment 3: refer to figure 1 and Figure 5 , the difference in connection with the basis of Embodiment 1 is that the fine polishing feeding device 5 includes a feeding belt 7, a second motor 34 and a first driven pulley 39, and the right end of the second motor 34 is fixedly connected There is a second driving shaft 35, a first driving pulley 36 is fixedly installed in the middle part of the second driving shaft 35, a second driving pulley 37 is fixedly installed at the right end of the second driving shaft 35, and the first driving pulley 36 is connected to the first driving pulley 35. The first driven pulley 39 is connected by transmission through the first belt 38, the right end of the first driven pulley 39 is fixedly connected with the first driving roller shaft 40, and the middle part of the first driving roller shaft 40 is fixedly equipped with a driving spur gear 41 , the right end of the first driving roller shaft 40 is fixedly equipped with a first driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com