Substation inspection robot with dual manipulators

An inspection robot and dual manipulator technology, applied in the field of intelligent robots, can solve the problems of small coverage, low work efficiency, low accuracy and timeliness, achieve strong action ability and load capacity, improve work efficiency, and operate conveniently and efficiently Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

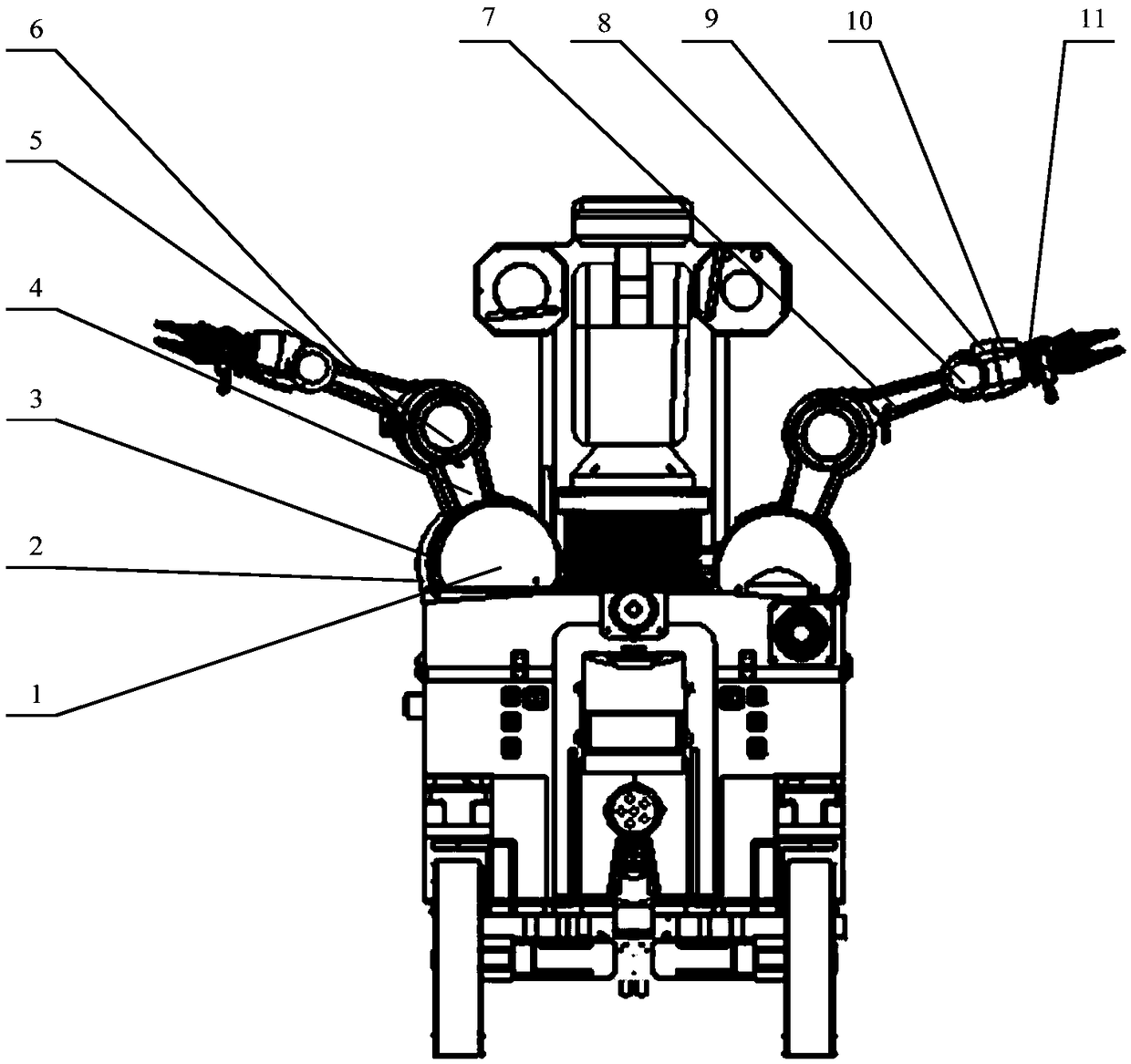

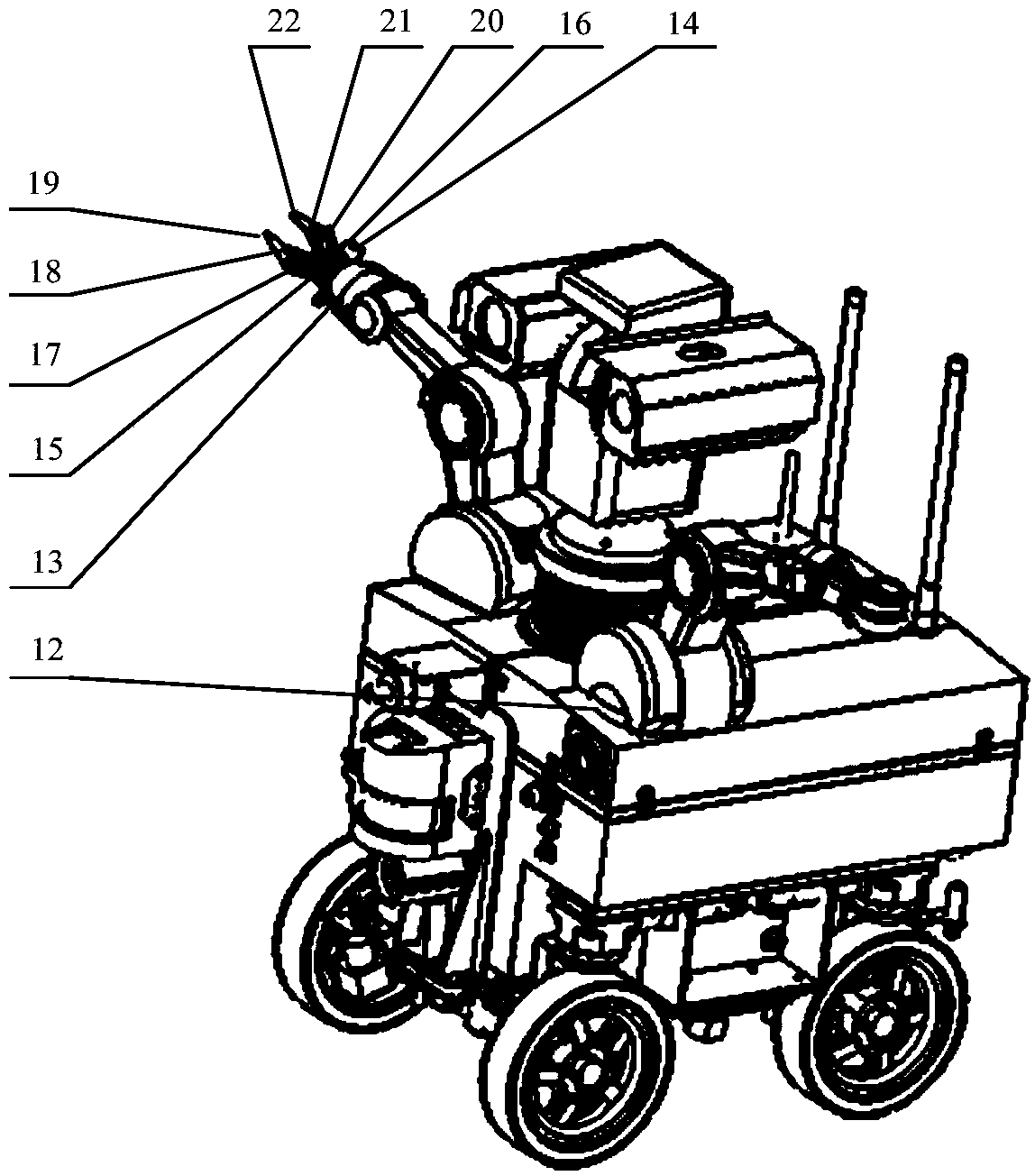

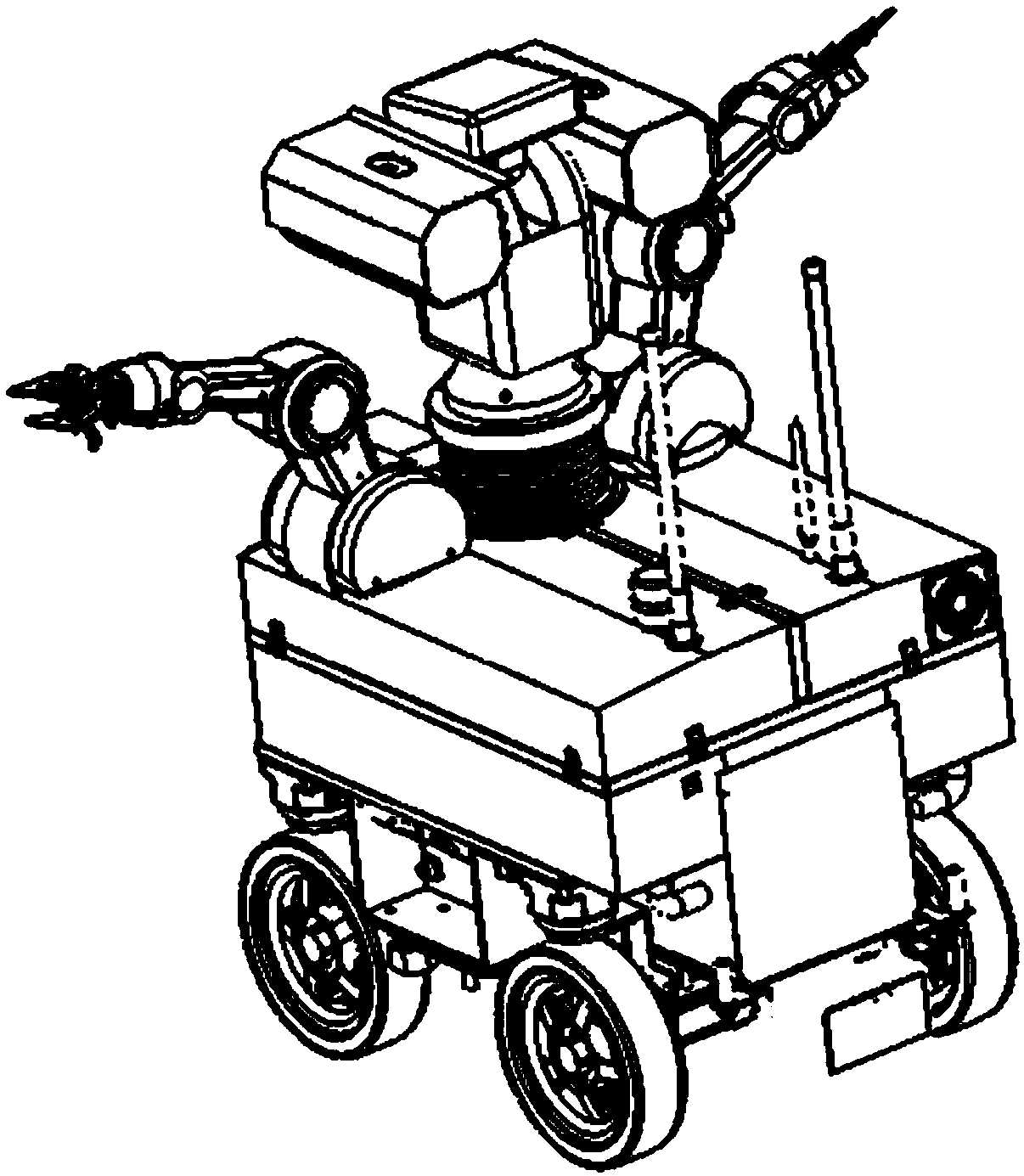

[0058] The substation inspection robot with double manipulators of the present invention, such as Figure 1-3 As shown, including the installation chassis, 2 adjustment arms and 2 manipulators;

[0059] The two manipulators have the same structure and are symmetrically installed on both sides of the inspection robot;

[0060] The installation chassis includes a rotating base 12 and a frame 2;

[0061] The adjusting arm includes a first motor 1, a first rotating shaft 3, a first joint arm 4, a second motor 5, a second rotating shaft 6, a second joint arm 7, a third motor 8, a third rotating shaft 13 and a third joint Arm 9, each section arm is located in the same plane and can rotate freely in this plane relative to the adjacent section arm;

[0062] The manipulator includes a manipulator shaft 10, a fourth motor 11, a mounting frame 14, a first knuckle 17, a fifth motor 15, a first pull rod 18, a first fingertip 19, a second knuckle 20, a sixth motor 16, The second pull rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com