Printer for industrial design

An industrial design and printer technology, applied in the direction of mechanical equipment, additive processing, manufacturing auxiliary devices, etc., can solve the problems that affect the accuracy of 3D printing, affect the printing quality, etc., achieve superior electrical conductivity, improve accuracy, and reduce jitter Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

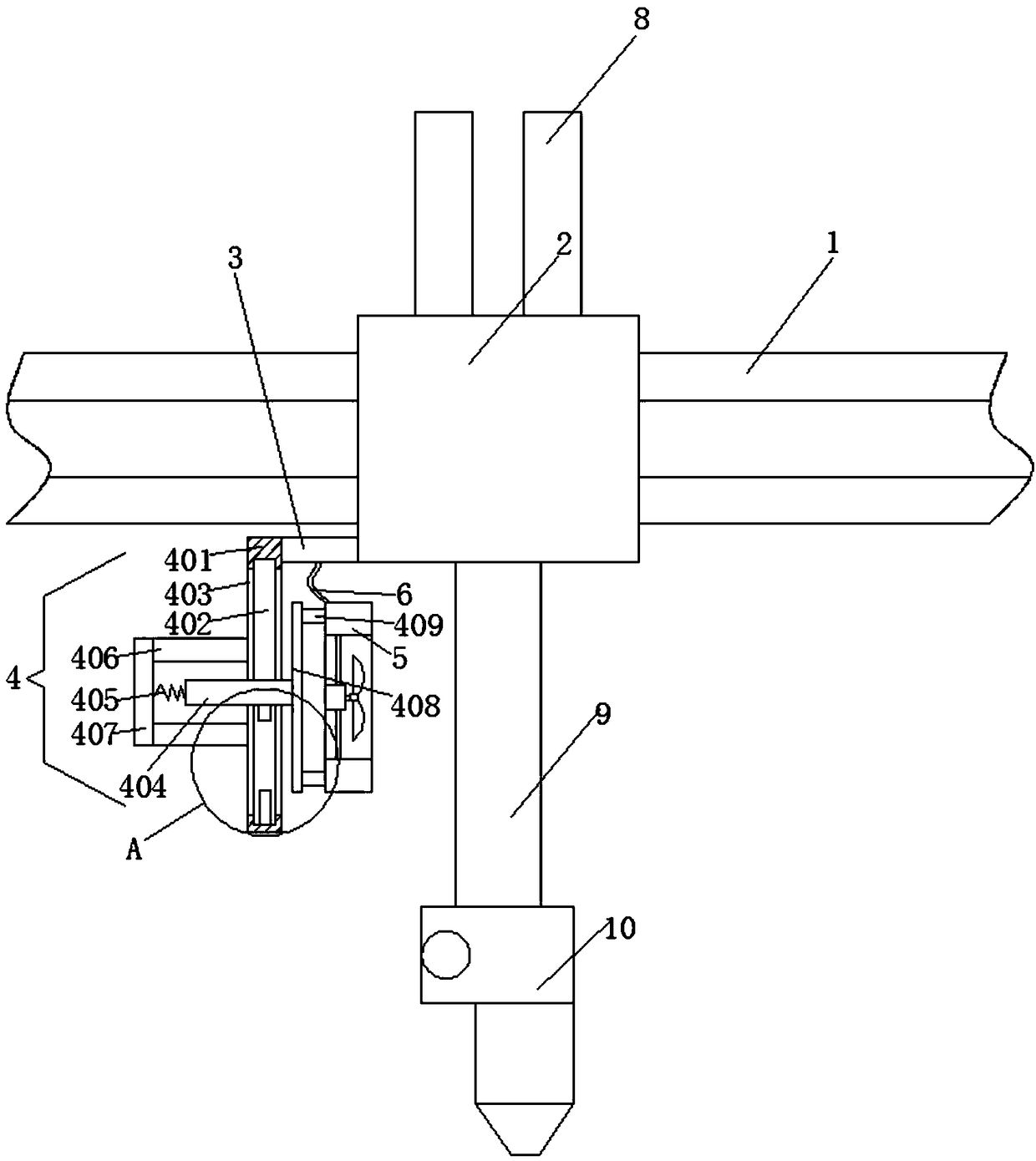

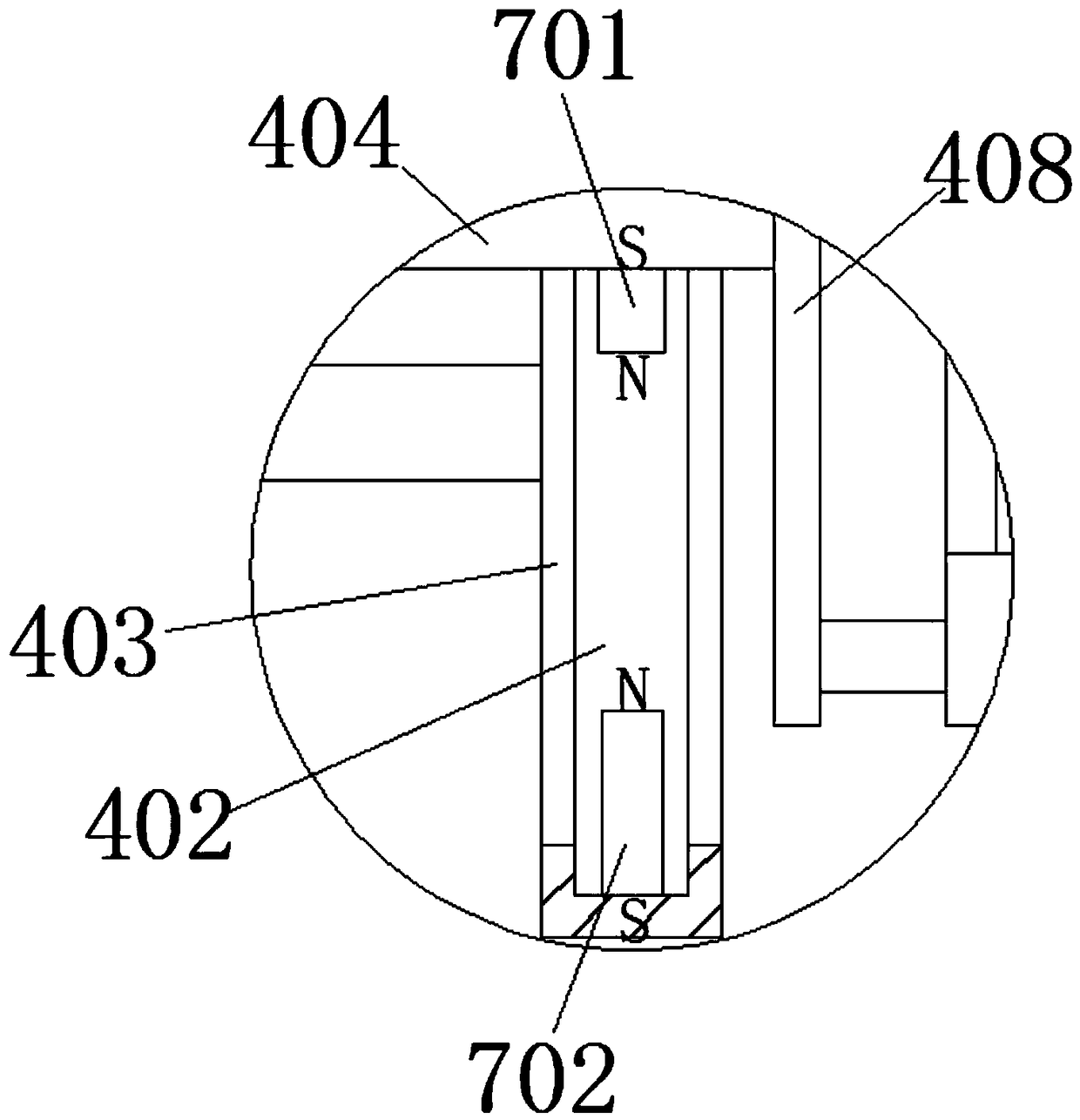

[0022] An embodiment of the present invention provides a printer for industrial design, such as Figure 1-2 As shown, including the X horizontal axis 1, the 3D printer is equipped with three axes, XYZ, and the transmission of the three axes is convenient for printing the print head in the movable space. The left side of 2 is located below the X horizontal axis 1 and is welded and fixed with the connection block 3. The left side of the connection block 3 is fixedly connected with a shock absorber 4, and the shock absorber 4 is connected with a cooling fan 5, and the input end of the cooling fan 5 Electrically connected with a flexible wire 6, the cooling fan 5 is connected through the flexible wire 6, and the flexible wire 6 is a soft connection of a copper braid. The copper-copper braid has excellent electrical conductivity and strong applicability. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com