Computer screen protective film production method

A production method and technology for computer screens, applied in chemical instruments and methods, electronic equipment, layered products, etc., can solve the problems of dust attached to the surface of the finished protective film, low efficiency, cumbersome process steps, etc., to ensure cleanliness and save money. Cost, effect of optimizing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

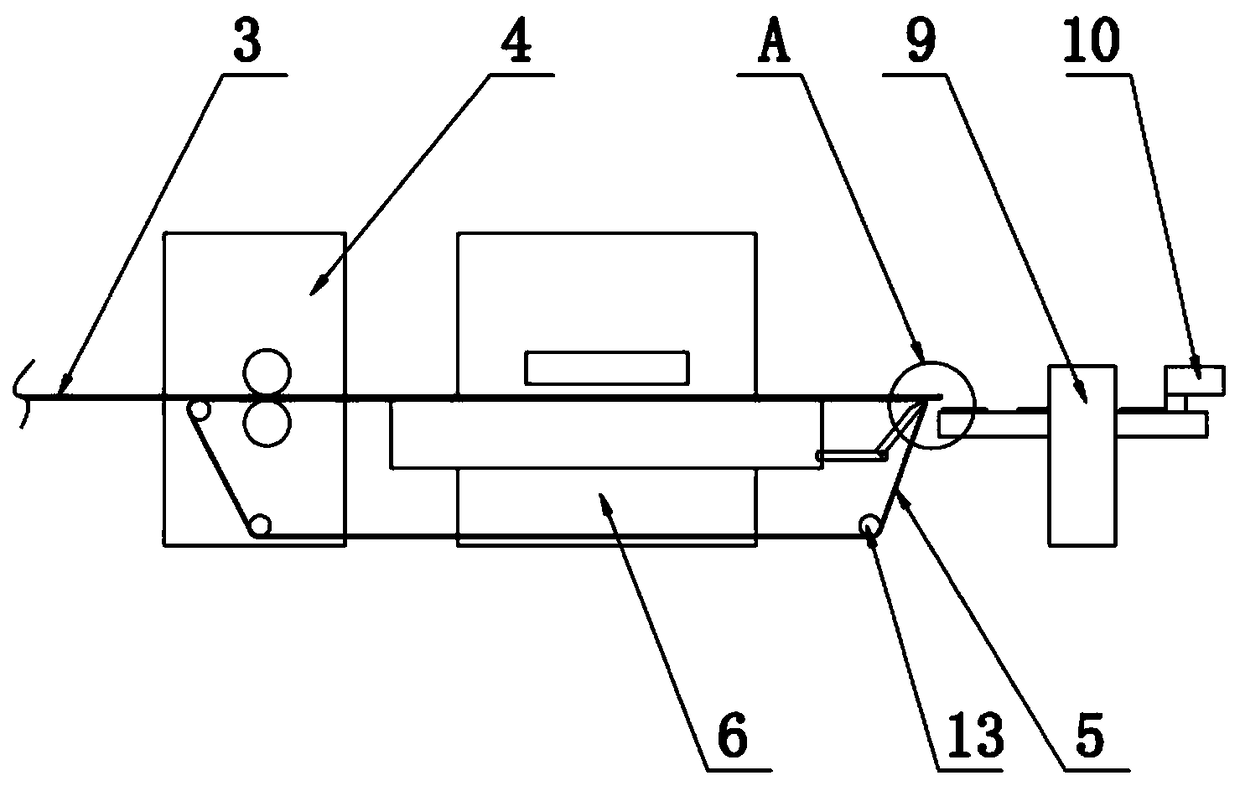

[0022] Such as Figure 1 to Figure 2 Shown; A kind of computer screen protection film production method of the present invention comprises the following steps:

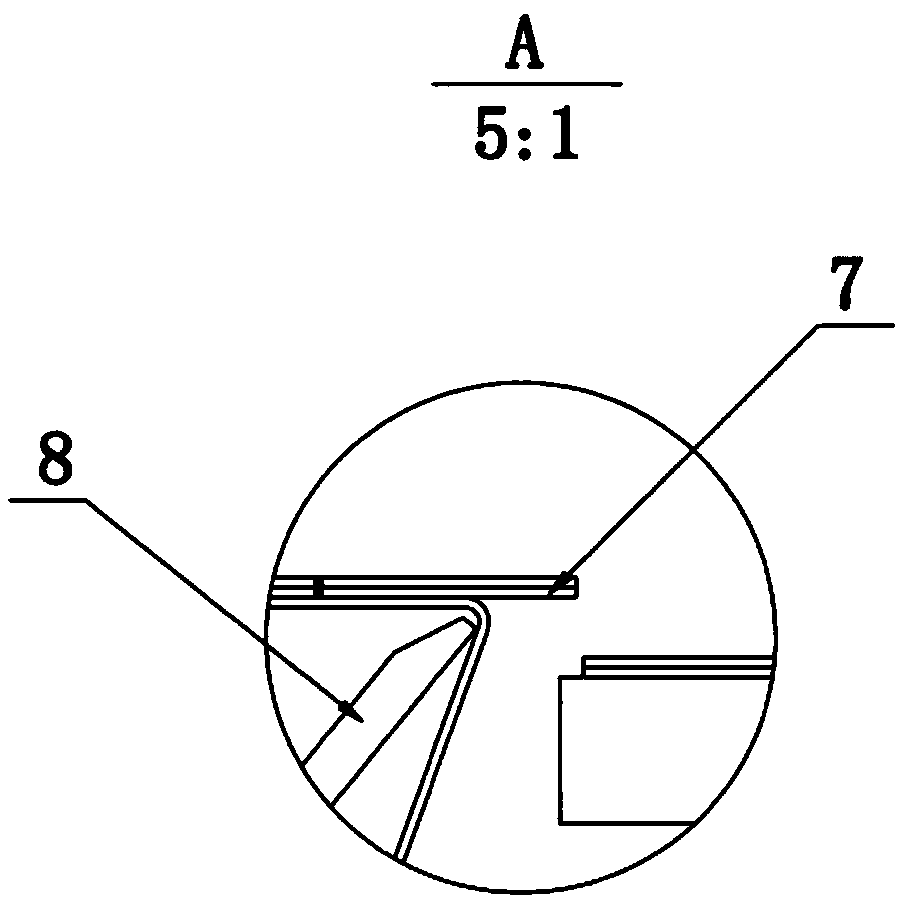

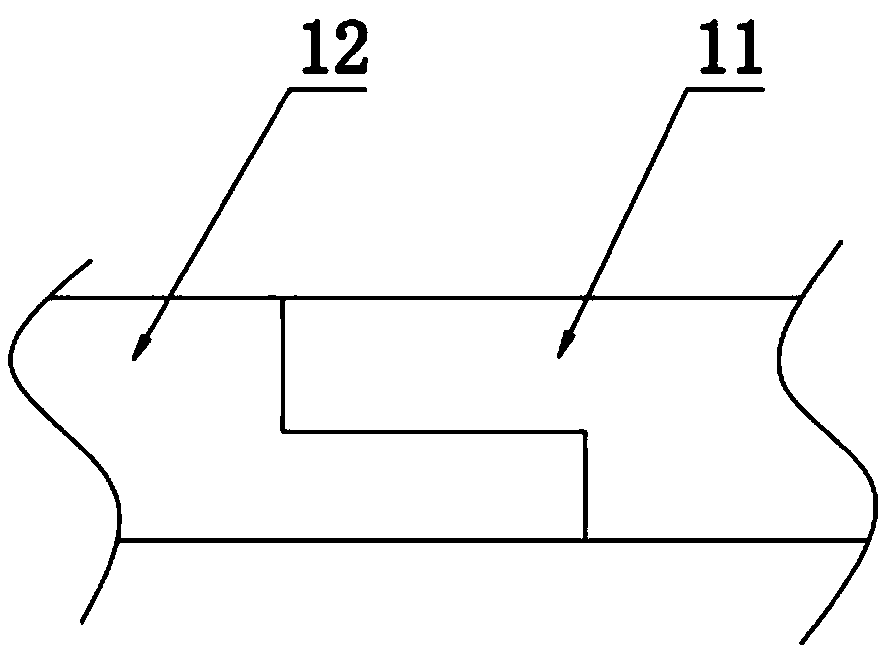

[0023] Step 1: Prepare materials, use the laminating machine 4 to compound the traction film 5 under the protective film 3 to obtain raw materials; Step 2: Die-cutting: Die-cut the protective film 3 into a rectangular body 7 through the die-cutting machine 6, and cut off; step Three: peeling: the traction film 5 bypasses the top of the scraper 8 and pulls downward, the rectangular body 7 continues to move horizontally and separates from the traction film 5; step 4: dust removal, the rectangular body 7 falls down onto the conveyor belt of the electrostatic precipitator 9, The dust on the surface of the rectangular body 7 is removed by an electrostatic precipitator 9; step 5: static...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com