A hybrid power system and its cold start method

A hybrid system and hybrid technology, applied in hybrid vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of high startup noise, increase production costs, and long startup time, reduce capacity requirements, and reduce material costs. , the effect of saving interior space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the purpose and features of the present invention more obvious and understandable, the specific implementation of the present invention will be further described below in conjunction with the accompanying drawings. However, the present invention can be implemented in different forms and should not be limited to the described embodiments.

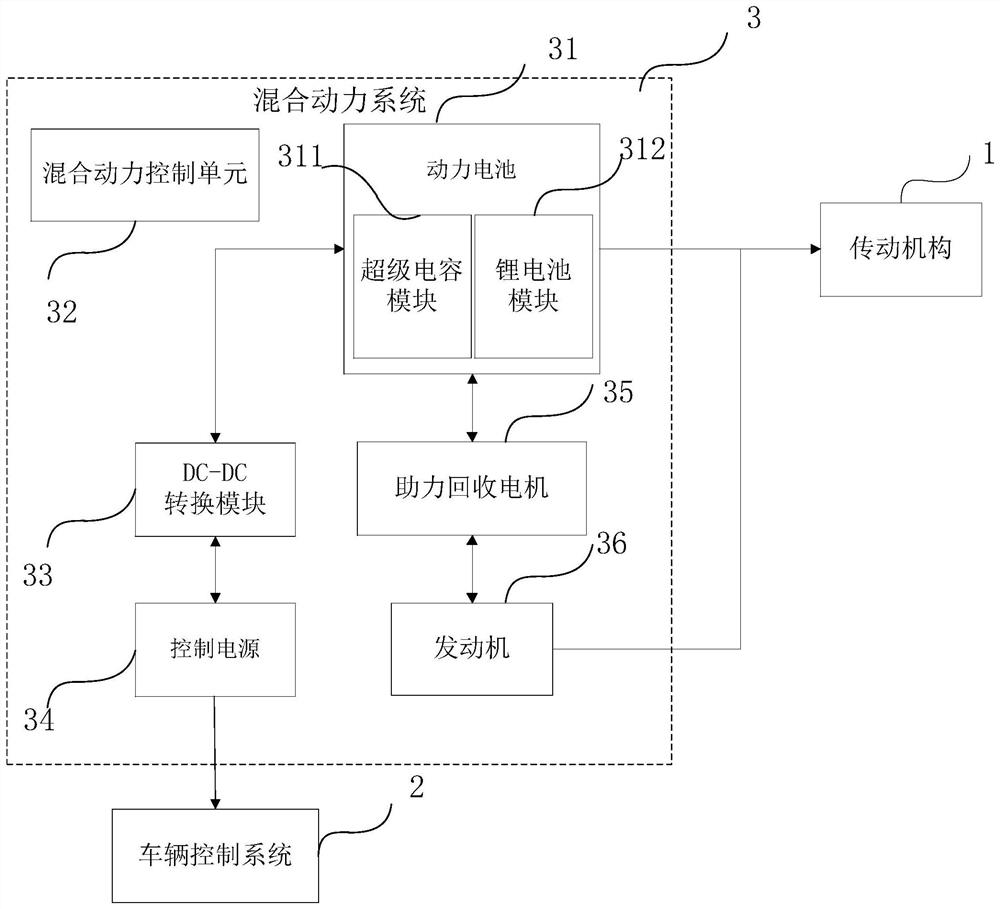

[0053] Such as figure 2 A hybrid system 3 shown includes a power battery 31 , a hybrid control unit 32 (connection not shown), a DC-DC conversion module 33 , a control power supply 34 , a power recovery motor 35 , and an engine 36 . The power battery 31 is connected with the transmission mechanism 1 in the vehicle, and provides power for the transmission mechanism 1, so that the vehicle moves. The power battery 31 and the engine 36 time-sharingly drive the transmission mechanism 1 according to the following principles:

[0054]a. When the vehicle is running normally, the engine 36 is in working condition, and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com