Multifunctional mechanical arm grabbing mechanism

A multi-functional manipulator and grasping mechanism technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of low degree of automation, increased equipment volume, complex structure, etc., and achieves high degree of automation, high functional integration, Compact and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

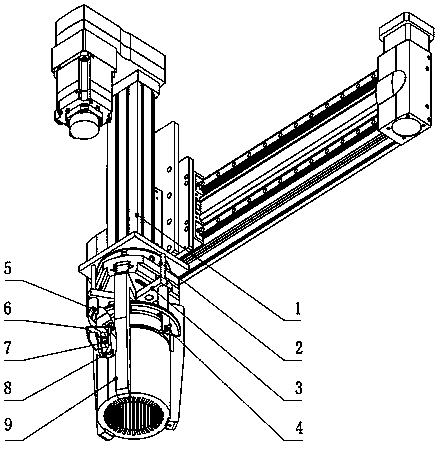

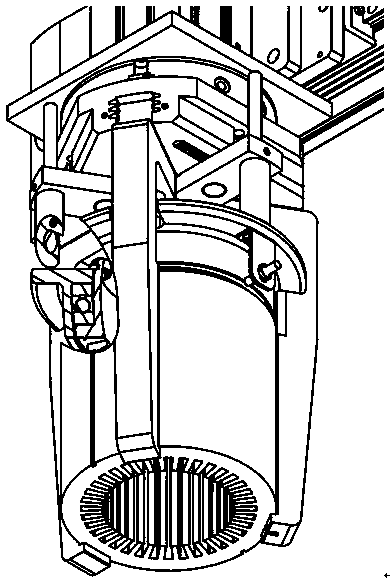

[0012] Specific implementation method: reference figure 1 , figure 2 , a multi-functional manipulator grabbing mechanism, mainly composed of a manipulator 1 driven by a lifting servo electric cylinder and a horizontal servo electric cylinder. The lower end of the manipulator 1 is provided with an air claw connected with an opening and closing jaw 9, and the lower end of the air pawl is provided with a compression substrate. 3. Install the adjustment shaft 2 in the guide hole on the compression base plate 3. The lower end of the adjustment shaft 2 is fixedly connected with the compression sleeve 8 provided on the lower side of the compression base plate 3. There is a stacked thickness between the compression base plate 3 and the compression sleeve 8. The limit block 5 and the pressure ring 6 are set in the pressure sleeve 8 through the bearing 7 inside the pressure sleeve 8 , and an induction switch 4 is provided on one side of the pressure sleeve 8 .

[0013] When working, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com