A kind of production technology of high-quality sodium thiocyanate

A sodium thiocyanate and production process technology, applied in the field of high-quality sodium thiocyanate production process, can solve the problems of low product purity, high raw material cost, high cost, etc., to increase economic benefits, improve product purity, and reduce raw material cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

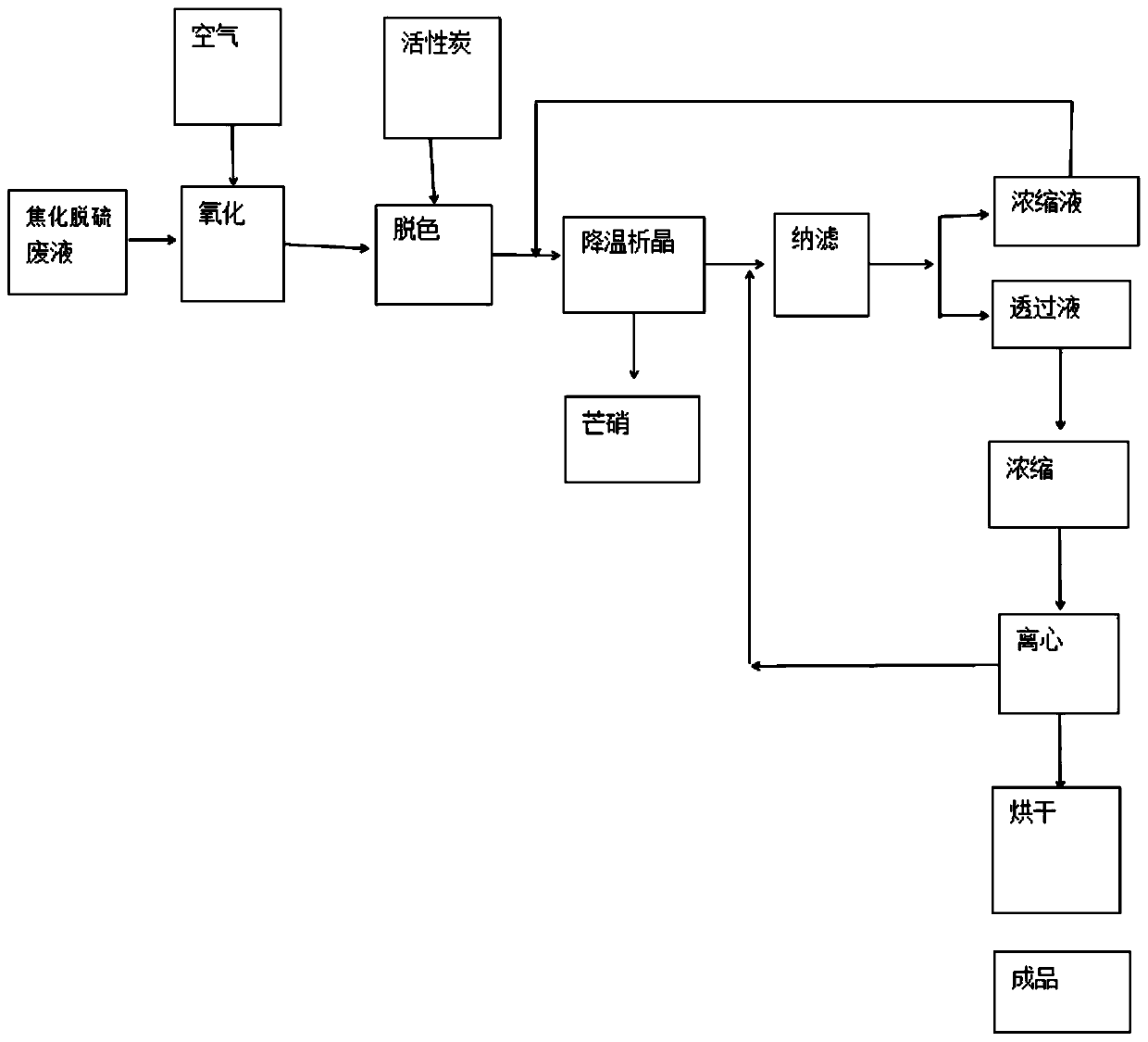

Method used

Image

Examples

Embodiment 1

[0035] With 5000g of coking desulfurization waste liquid (ammonium thiosulfate: 2.2%, ammonium sulfate: 2.5%, ammonium thiocyanate: 15%), the temperature is raised to 60°C, the amount of oxygen in the air is equal to the mole of ammonium thiosulfate The ratio is 1:1, the residence time of the gas in the solution is 10 seconds, oxidize for 4 hours, then add 10g of activated carbon for decolorization, decolorize at 40°C for 6 hours or repeatedly filter through activated carbon fibers for 6 times, add 1655g (32% ) liquid sodium hydroxide, warming up to 100°C and catching up with ammonia for 6 hours, the stirring speed was 72rpm, the ammonia content in the feed liquid after the ammonia was discharged was 30ppm, the temperature was lowered to -10°C, the stirring speed was 20rpm, crystallization was carried out for 1 hour, and filtered to obtain ten Sodium sulfate water crystalline solid: 436g, the filtrate continued to enter the nanofiltration membrane filtration system for filtrati...

Embodiment 2

[0037]With 5000g of coking desulfurization waste liquid (wherein ammonium thiosulfate: 2.2%, ammonium sulfate: 2.5%, ammonium thiocyanate: 15%), the temperature is raised to 100°C, and the amount of oxygen in the air is equal to the mole of ammonium thiosulfate The ratio is 1:5, the residence time of the gas in the solution is 5 seconds, oxidize for 1 hour, then add 50g of activated carbon for decolorization, decolorize at 80°C for 1 hour or repeatedly filter through activated carbon fiber for 6 times, add 1655g (32% ) liquid sodium hydroxide, the temperature was raised to 80° C. to catch ammonia for 2 hours, the stirring speed was 72 rpm, the ammonia content in the feed liquid after the ammonia discharge was 25 ppm, and the feed liquid after the ammonia discharge was cooled to 0° C. together with the previous batch of nanofiltration concentrates. Stirring speed 20rpm, crystallize for 4 hours, filter to obtain sodium sulfate decahydrate crystalline solid: 522g, the filtrate con...

Embodiment 3

[0039] With 5000g of coking desulfurization waste liquid (wherein ammonium thiosulfate: 2.2%, ammonium sulfate: 2.5%, ammonium thiocyanate: 15%), be warmed up to 80 ℃, the amount of oxygen in the air and the mole of ammonium thiosulfate The ratio is 1:2, the residence time of the gas in the solution is 8 seconds, oxidize for 3 hours, then add 20g of activated carbon for decolorization, decolorize at 60°C for 3 hours or repeatedly filter through activated carbon fibers for 6 times, add 1655g (32% ) liquid sodium hydroxide, the temperature was raised to 90° C. to catch ammonia for 4 hours, the stirring speed was 72 rpm, the ammonia content in the feed liquid after the ammonia discharge was 40 ppm, and the feed liquid after the ammonia discharge was cooled to 0° C. together with the last batch of nanofiltration concentrates. The feed liquid after ammonia removal is cooled to -5°C together with the previous batch of concentrated nanofiltration liquid, crystallized for 2 hours and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com