A kind of building material with high sound insulation epoxy resin

An epoxy resin, a technology used in construction, applied in the field of building materials, can solve the problems of poor mechanical properties of sound insulation boards, heat insulation performance decline, etc., achieve high elasticity and flexural resistance, improve stability, and improve the effects of controlled release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

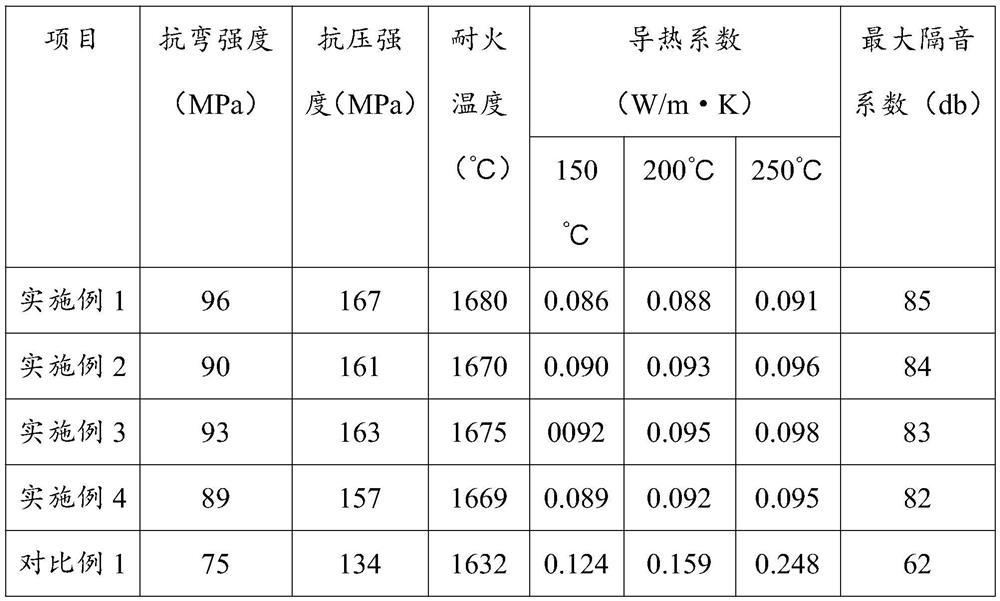

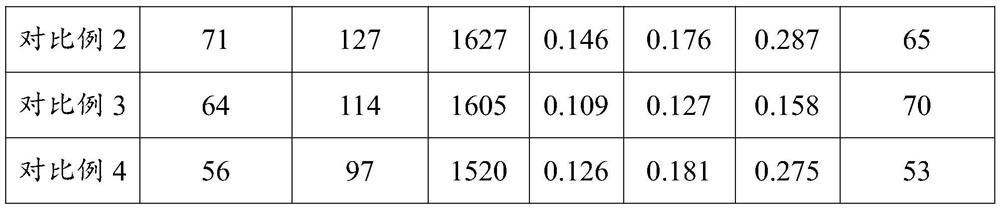

Examples

Embodiment 1

[0036] A high-sound-insulation epoxy resin building material for buildings comprises a thermal-radiation-resistant layer, a sound-insulation layer, and a base layer that are heat-pressed sequentially from the outside to the inside. The thickness of the anti-heat radiation layer is 0.8-1.1cm, the thickness of the sound insulation layer is 0.6-0.8cm, and the thickness of the base layer is 1.5-2.2cm.

[0037] The sound insulation layer includes the following raw materials in parts by weight: 9 parts of bisphenol A epoxy resin, 4 parts of zinc borate hydrate, 0.3 part of antimony trioxide, 78 parts of nano-sized magnesium oxide, 33 parts of magnesium chloride hexahydrate, fly ash 10 parts, 5.5 parts of carboxymethyl chitosan / sodium alginate embedded silica airgel microspheres. Wherein, the content of zinc oxide in the hydrated zinc borate is 36-40%, the content of boron oxide is 45-49%, and the loss on ignition is 13-15.5%. SiO in fly ash 2 、Al 2 o 3 , Fe 2 o 3 The content o...

Embodiment 2

[0053] A high-sound-insulation epoxy resin building material for buildings comprises a thermal-radiation-resistant layer, a sound-insulation layer, and a base layer that are heat-pressed sequentially from the outside to the inside. The thickness of the anti-heat radiation layer is 0.8-1.1cm, the thickness of the sound insulation layer is 0.6-0.8cm, and the thickness of the base layer is 1.5-2.2cm.

[0054] The sound insulation layer includes the following raw materials in parts by weight: 11 parts of bisphenol A epoxy resin, 5 parts of zinc borate hydrate, 0.6 parts of antimony trioxide, 76 parts of nano-sized magnesium oxide, 27 parts of magnesium chloride hexahydrate, fly ash 8 parts, carboxymethyl chitosan / sodium alginate embedded silica airgel microspheres 6.5 parts. Wherein, the content of zinc oxide in the hydrated zinc borate is 36-40%, the content of boron oxide is 45-49%, and the loss on ignition is 13-15.5%. SiO in fly ash 2 、Al 2 o 3 , Fe 2 o 3 The content of ...

Embodiment 3

[0062] The invention relates to a high-sound-insulation epoxy resin building material for building, which comprises a heat-radiation-resistant layer, a sound-insulation layer, and a base layer which are heat-pressed sequentially from the outside to the inside. The thickness of the anti-heat radiation layer is 0.8-1.1cm, the thickness of the sound insulation layer is 0.6-0.8cm, and the thickness of the base layer is 1.5-2.2cm.

[0063] The sound insulation layer includes the following raw materials in parts by weight: 10 parts of bisphenol A epoxy resin, 4 parts of zinc borate hydrate, 0.5 part of antimony trioxide, 82 parts of nano-sized magnesium oxide, 32 parts of magnesium chloride hexahydrate, fly ash 12 parts, 7.6 parts of carboxymethyl chitosan / sodium alginate embedded silica airgel microspheres. Wherein, the content of zinc oxide in the hydrated zinc borate is 36-40%, the content of boron oxide is 45-49%, and the loss on ignition is 13-15.5%. SiO in fly ash 2 、Al 2 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com