Zincate barrel plating galvanizing liquid recycling device

A recycling and zincate technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of non-environmental protection, waste, etc., and achieve the effect of preventing internal vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

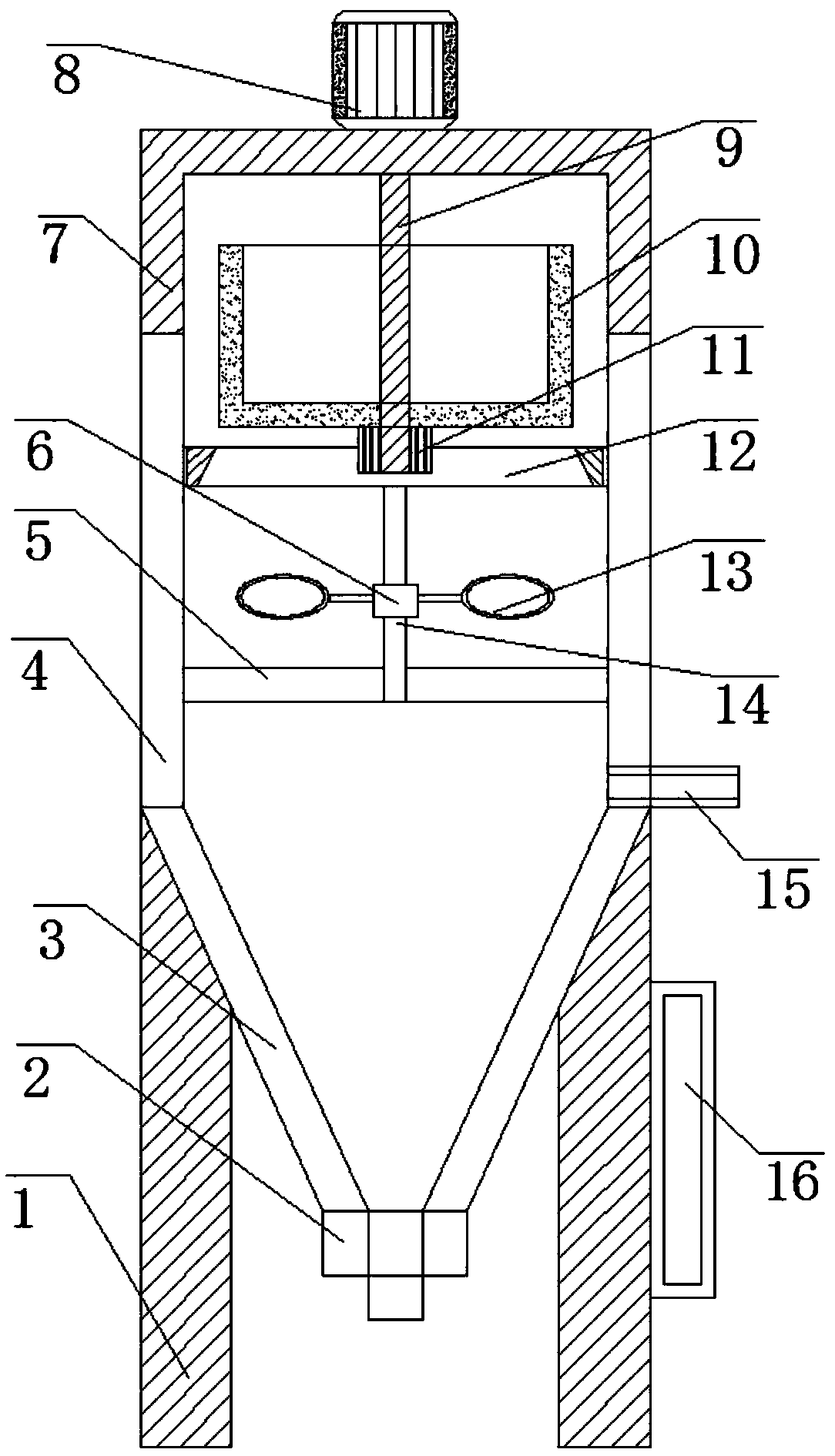

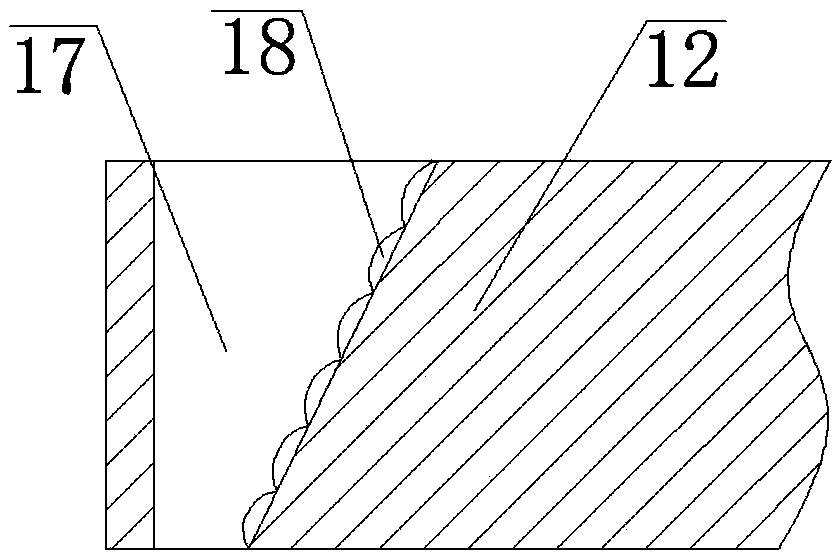

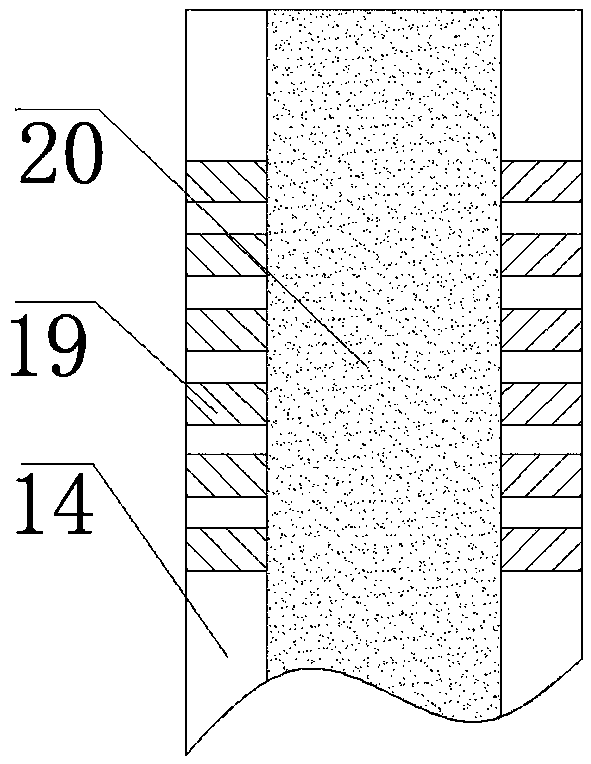

[0022] refer to Figure 1-3 , a zincate barrel galvanizing bath recycling device, comprising a main tank 4, the bottom of the main tank 4 is connected with a debugging bottom tank 3 by bolts, and the top of the peripheral outer wall of the debugging bottom tank 3 is connected with two bolts. A main support frame 1, the bottom of the debugging bottom tank 3 is connected with a liquid outlet valve 2 through bolts, and the top of the main tank body 4 is connected with a separated top tank 7 through bolts, and the top of the separated top tank 7 is provided with a material injection hole. The top of the circumferential inner wall of the tank body 4 is connected with a su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap