Anti-pleating suit fabric and preparation method thereof

A technology of fabrics and suits, applied in the textile field, can solve the problems of washing resistance, easy wrinkling, high energy consumption, etc., and achieve the best anti-wrinkle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] A preparation method of anti-wrinkle suit fabric, which comprises:

[0016] Blending wool and polyester into a single yarn, plying two single yarns to make a ply, and weaving the ply into a wrinkle-resistant suiting fabric;

[0017] Among them, the twist of the single yarn is 630-810 T / M, and the twist of the ply yarn is 1100-1450 T / M.

[0018] Traditional wool worsted dress fabrics have a rich, elastic, stiff and cool style and good wearing comfort. However, in the prior art, although the wrinkle resistance of traditional wool worsted dress fabrics is better than that of cotton and linen, it is still easy to wrinkle when worn in a humid environment. In order to improve the anti-wrinkle performance of traditional wool worsted dress fabrics, it is necessary to use anti-wrinkle additives during the dyeing and finishing process. Washable.

[0019] Based on the above reasons, the embodiments of the present invention provide a method for improving the anti-wrinkle perform...

Embodiment 1

[0031] The embodiment of the present invention provides a kind of wrinkle-resistant suit fabric, and its preparation method is as follows:

[0032] Wool and polyester are blended into a single yarn, and the two single yarns are plyed to form a ply, and the ply is woven into the wrinkle-resistant suit fabric.

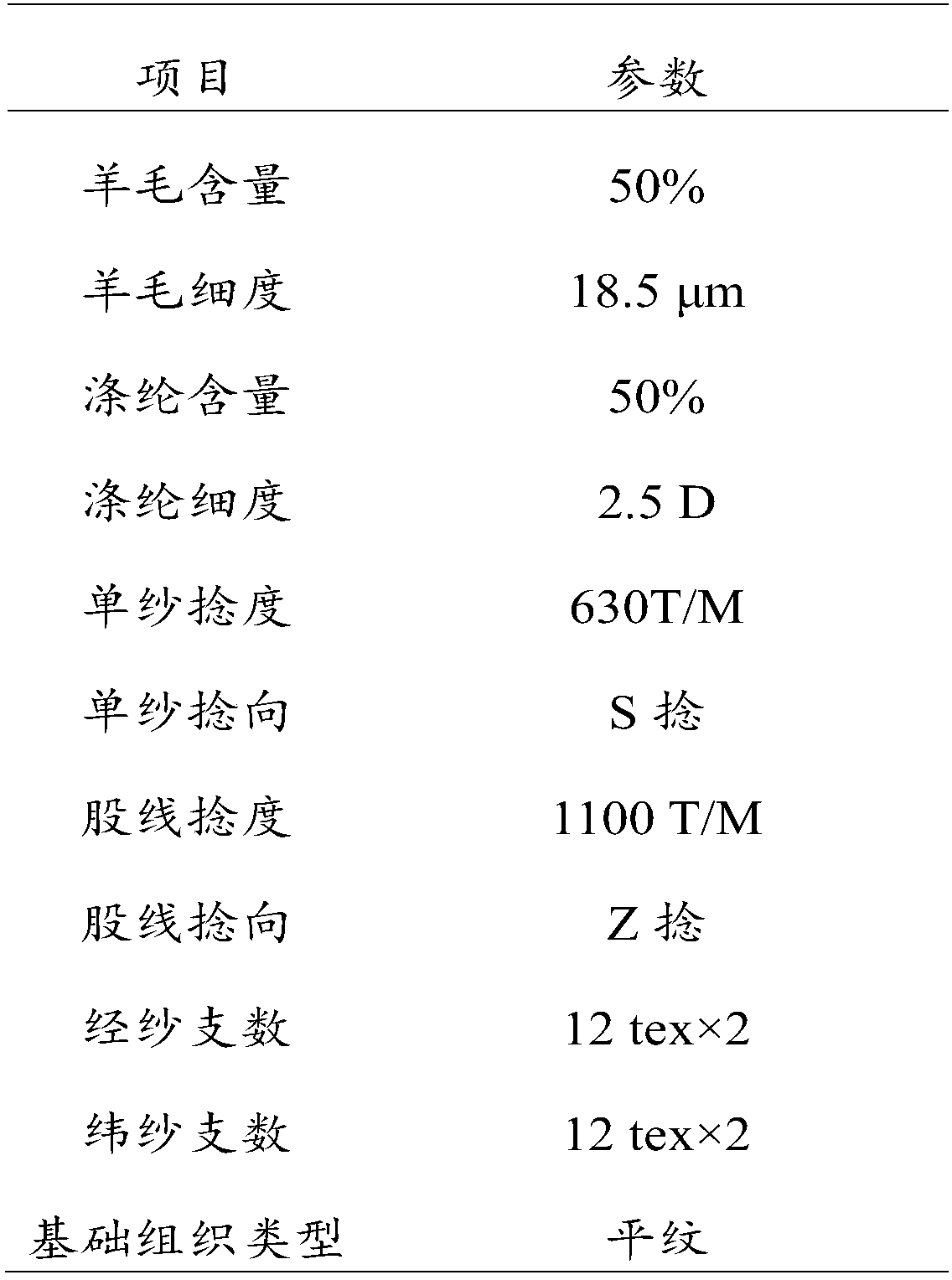

[0033] Its specific process parameters are as follows:

[0034]

[0035] The wrinkle-resistant suit fabric prepared in this embodiment has a sandy feel, light texture and good air permeability. The warp tightness is 45, the weft tightness is 36, and the total tightness reaches 81.

Embodiment 2

[0037] The embodiment of the present invention provides a kind of wrinkle-resistant suit fabric, and its preparation method is as follows:

[0038] Wool and polyester are blended into a single yarn, and the two single yarns are plyed to form a ply, and the ply is woven into the wrinkle-resistant suit fabric.

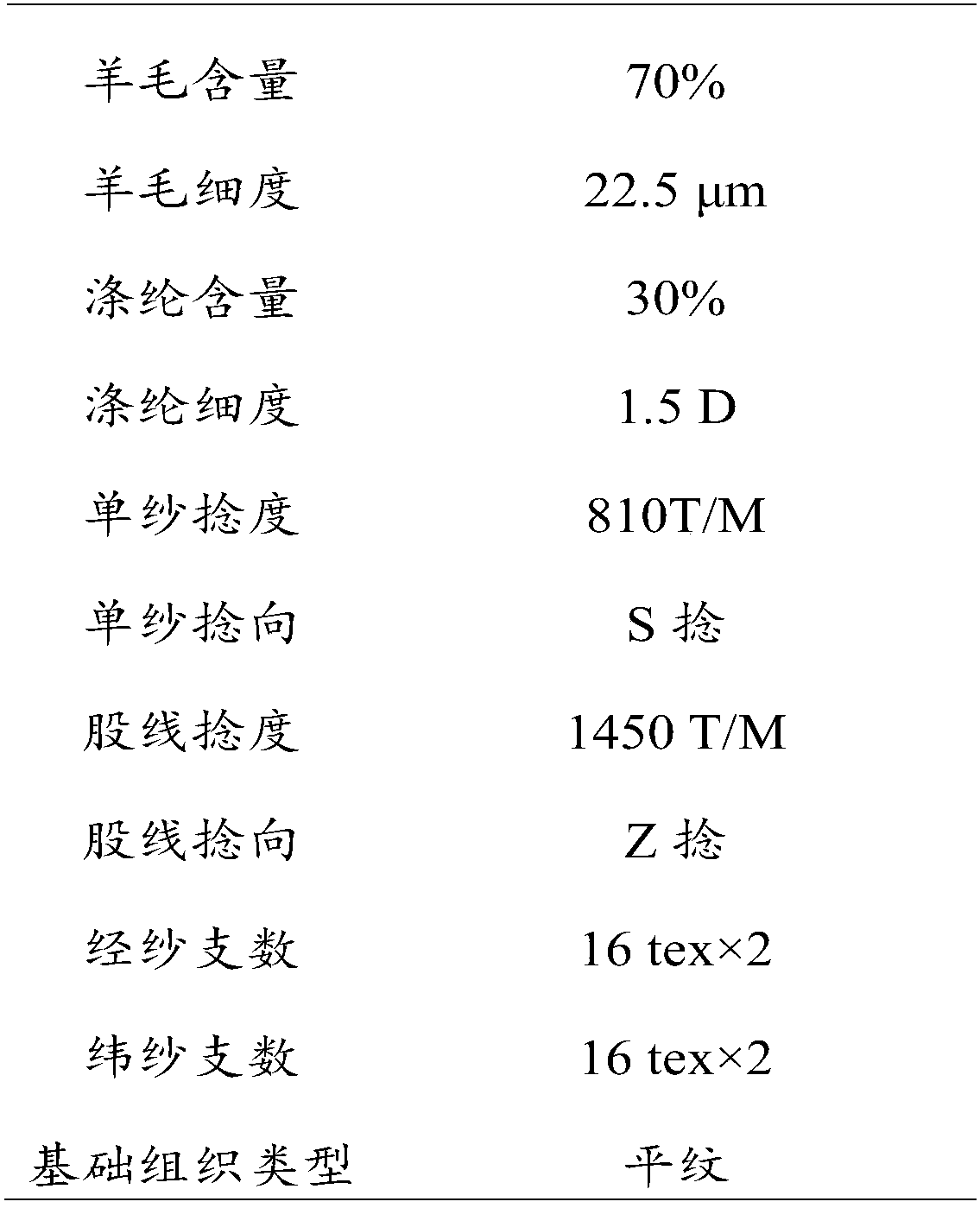

[0039] Its specific process parameters are as follows:

[0040]

[0041]

[0042] The wrinkle-resistant suit fabric prepared in this embodiment has a sandy feel, light texture and good air permeability. The warp tightness is 44, the weft tightness is 39, and the total tightness reaches 83.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Twist | aaaaa | aaaaa |

| Twist | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap