Quick-disassembled airbag floating breakwater

一种浮式防波堤、防波堤的技术,应用在防波堤、突堤、堤岸等方向,能够解决缺少防波堤系统、维护成本高、花费大时间等问题,达到降低后期维护成本、节省成本、简化难度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

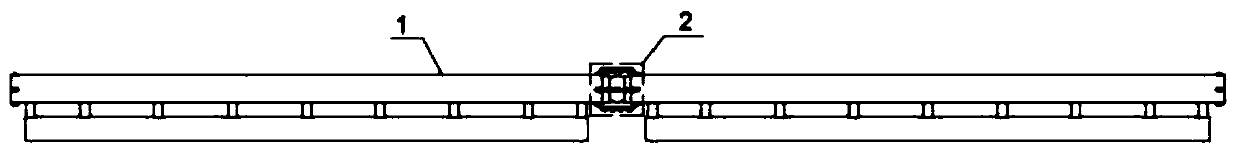

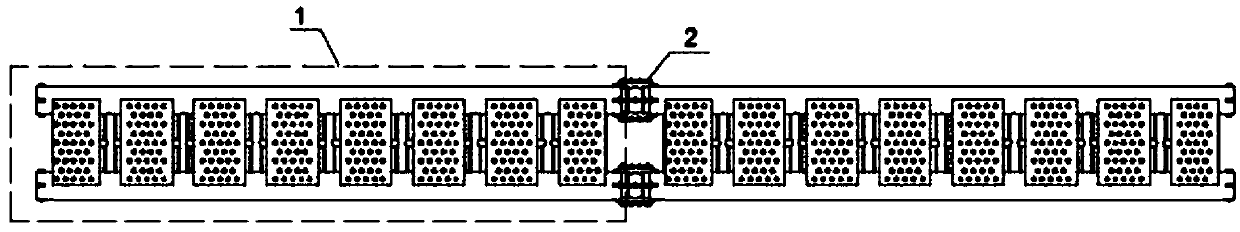

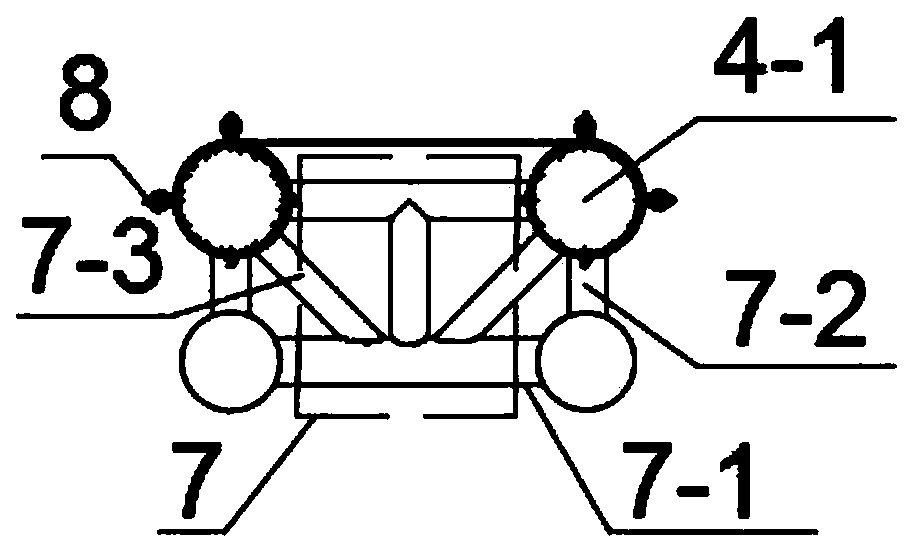

[0041] Such as figure 1 , 2 , 4, the air bag type floating breakwater of the present invention comprises some water surface wave-absorbing structural units 1 arranged along the length direction of the breakwater, adjacent water surface wave-absorbing structural units 1 are connected by connecting units 2, and water surface wave-absorbing structural units 1 are two The mooring system 3 can be symmetrically arranged on the side, and each water surface wave-absorbing structural unit 1 can be formed into a whole through the elastic connection of the connecting unit 2 and the limit function with the mooring system 3, so that it can move as a whole in the waves. against waves such as Figure 10-2 shown.

[0042] The water surface wave breaking structure unit 1 includes at least two buoys arranged side by side and a wave breaking plate 4-2 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com