Construction method for dismounting reinforced concrete supporting beam with assistance of hydraulic lifting bearing platform

A reinforced concrete and load-bearing platform technology, applied in excavation, infrastructure engineering, building maintenance, etc., can solve problems such as large dust, high construction cost, and environmental impact around reinforced concrete support beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

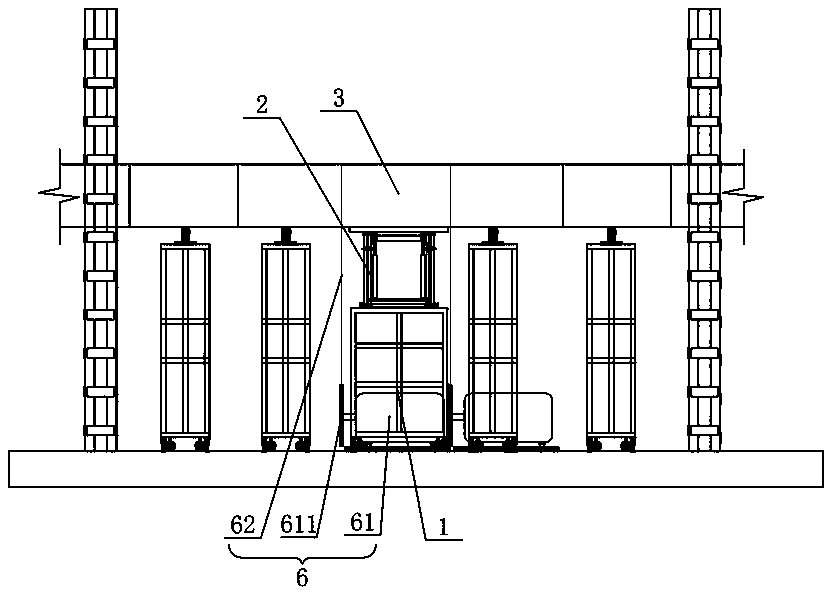

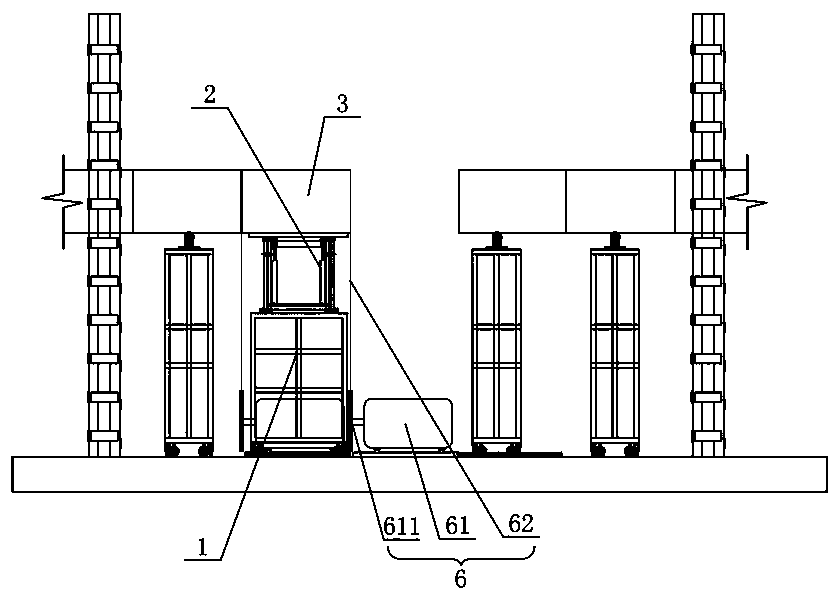

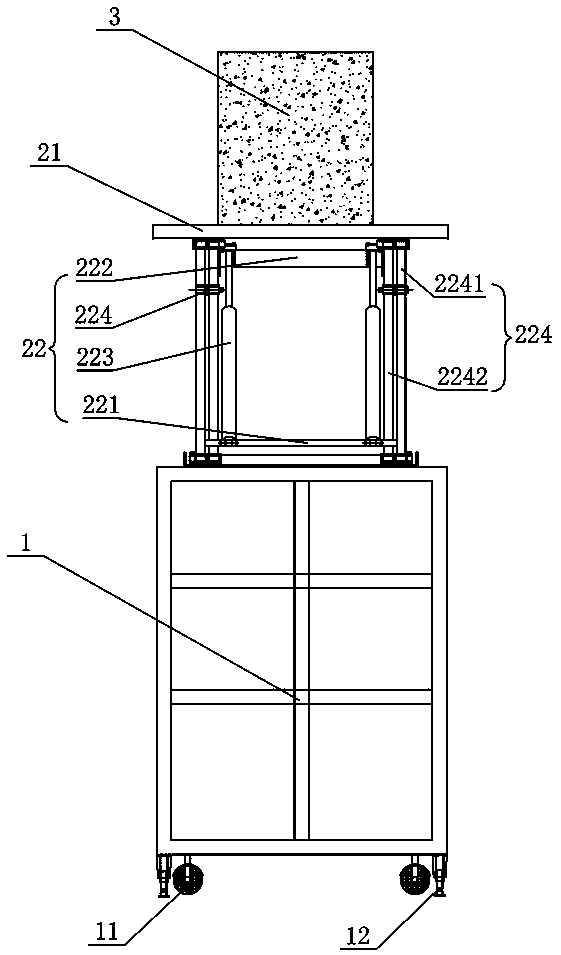

[0029] figure 1 and figure 2 Shows the construction method of the hydraulic lifting load-bearing platform of this embodiment to assist in the removal of reinforced concrete support beams. The hydraulic lifting load-bearing platform includes a mobile underframe 1 and a hydraulic lifting device 2 for supporting the segment beam 3 of the reinforced concrete support beam. The lifting device 2 is arranged on the top of the mobile chassis 1; the construction method includes the following steps:

[0030] S1: Move the hydraulic lifting load-bearing platform directly below the section beam 3, start the hydraulic lifting device 2, and make it support the section beam 3;

[0031] S2: Fixing frames 5 are installed directly below other segment beams 3, and each fixing frame 5 supports the segment beams 3 above it;

[0032] S3: cutting the sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com