Full prefabricated superposed pipe gallery integrated waterproof structure and construction method

A prefabricated assembly and waterproof structure technology, which is applied to underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of insufficient construction experience, uncompleted specifications and standards, and difficult construction, so as to improve the overall waterproof quality, Enhance the self-waterproof quality of the structure and the effect of easy quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

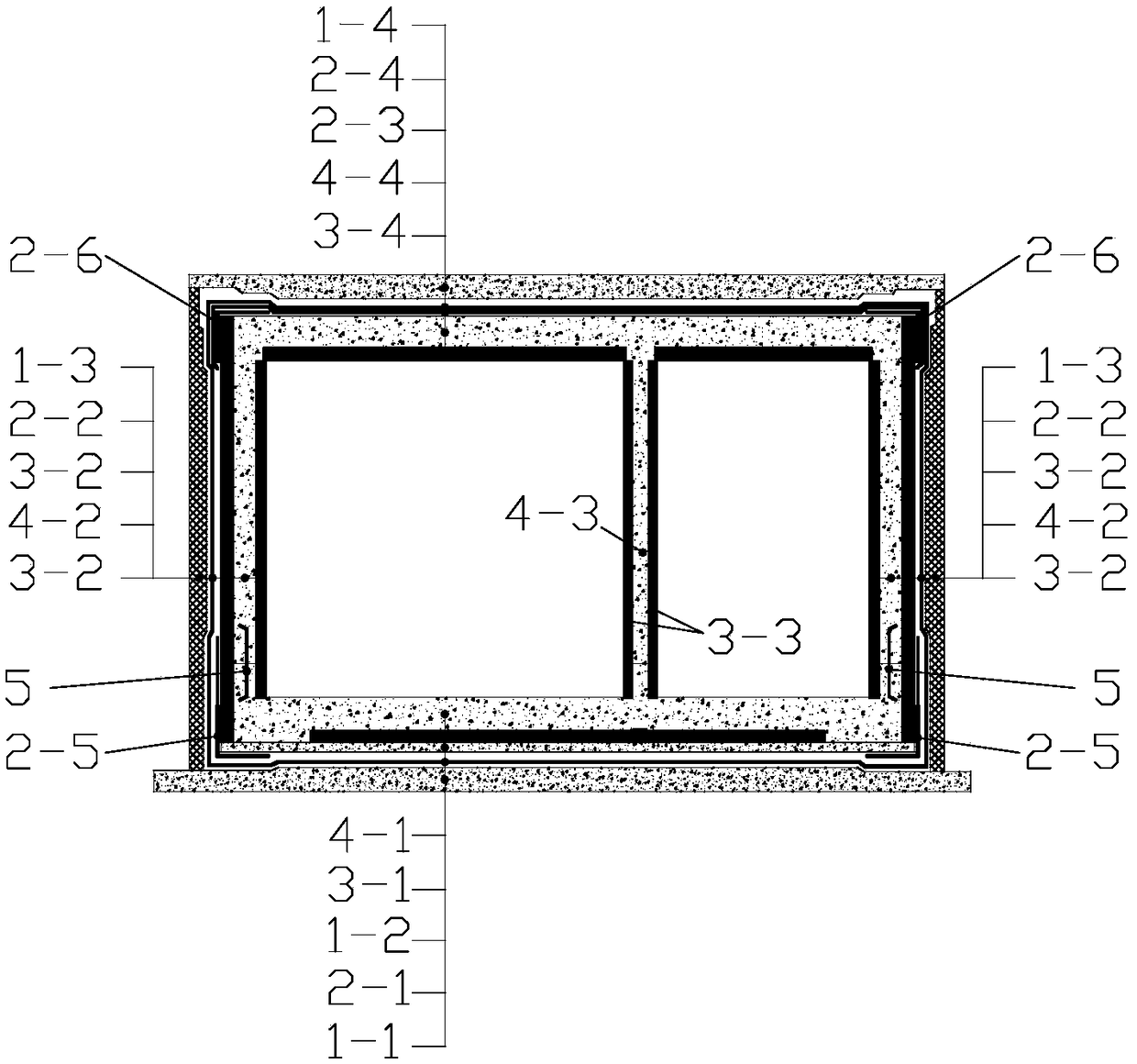

[0054] A double-compartment urban underground comprehensive pipe corridor, including gas tank and comprehensive tank, has a total width of 6.25m and a total height of 3.8m, of which the gas tank is 2.5m wide and the comprehensive tank is 3.75m wide.

[0055] The specific construction steps are as follows:

[0056] Step 1, laying concrete cushion 1-1 and cement mortar leveling layer;

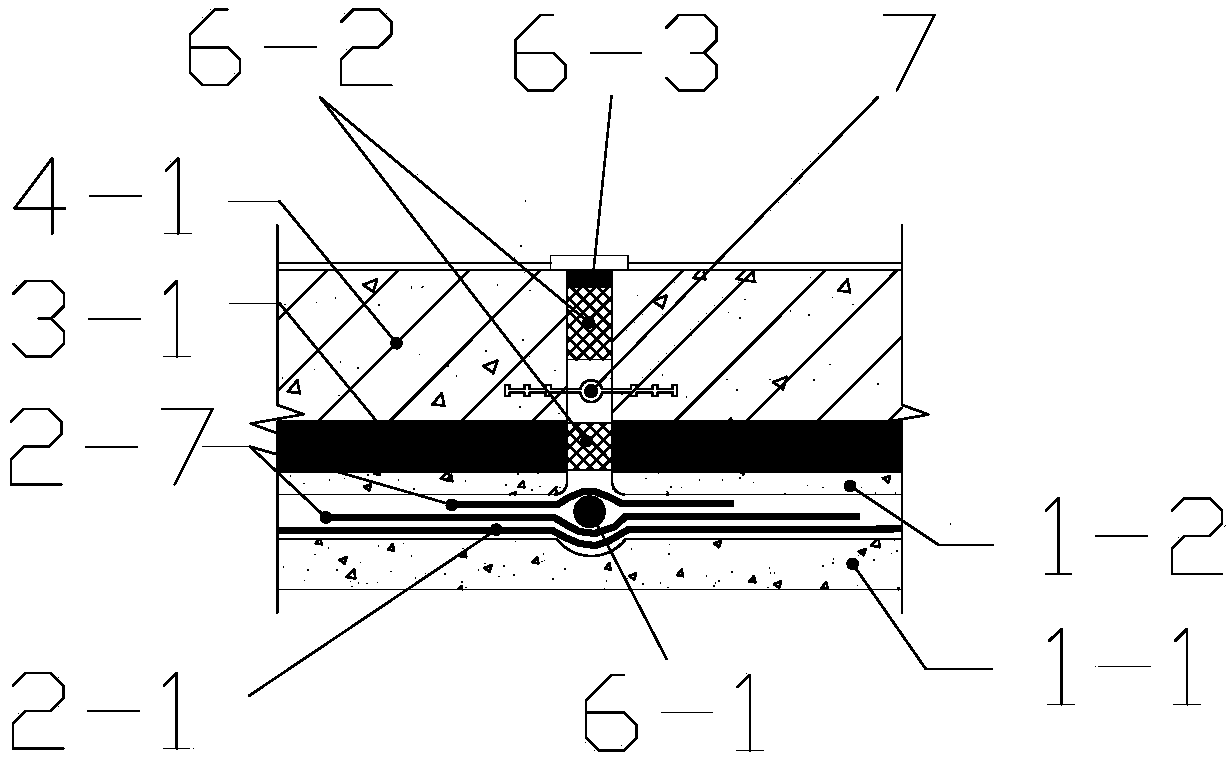

[0057] Step 2. Wet lay a waterproof membrane 2-1 at the bottom of the pipe gallery on the cement mortar, and lay a corner waterproof membrane reinforcement layer 2-5 and 2-6 on both sides of the bottom at the same time, and then lay a mortar isolation layer, and finally lay Fine stone concrete protective layer 1-2;

[0058] Step 3. After the fine stone concrete protective layer 1-2 reaches a certain strength, lay a layer of fine mortar, and then immediately lay the prefabricated floor laminated concrete 4-1;

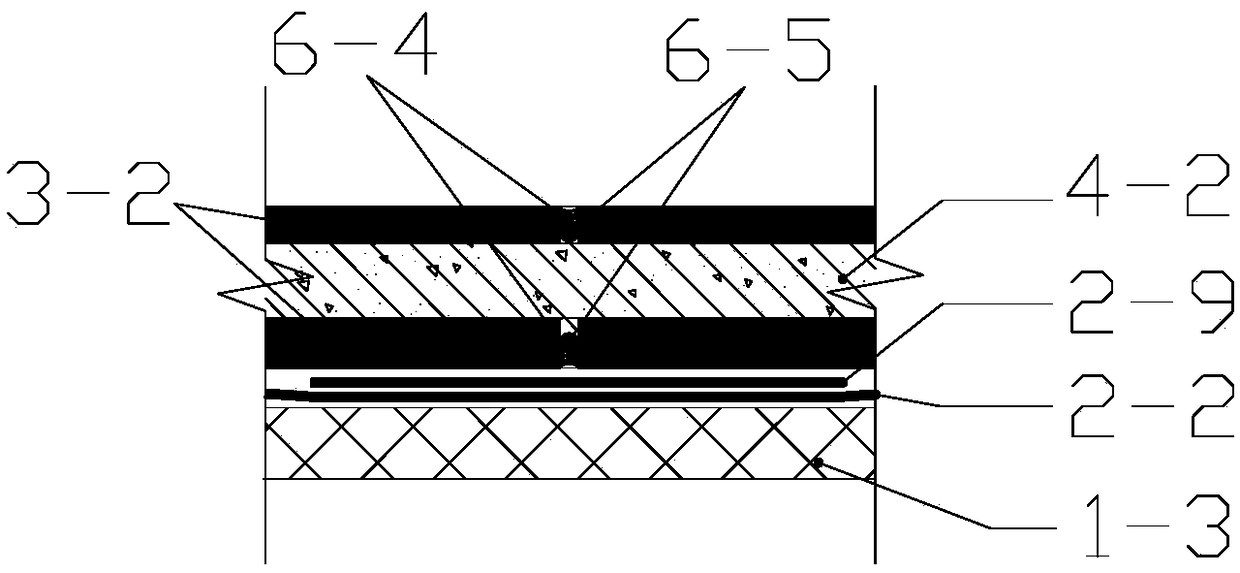

[0059] Step 4, laying prefabricated wall panels 3-2, 3-3, and supporting and fixing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com