Wave recorder fixing device with protecting function

A technology of fixing device and protection function, which is applied in the field of oscilloscope, can solve the problems of inconvenient operation, inability to change the direction and inclination angle during operation, and inconvenient operation for the operator, so as to achieve convenient operation, convenient installation and disassembly, and faster The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

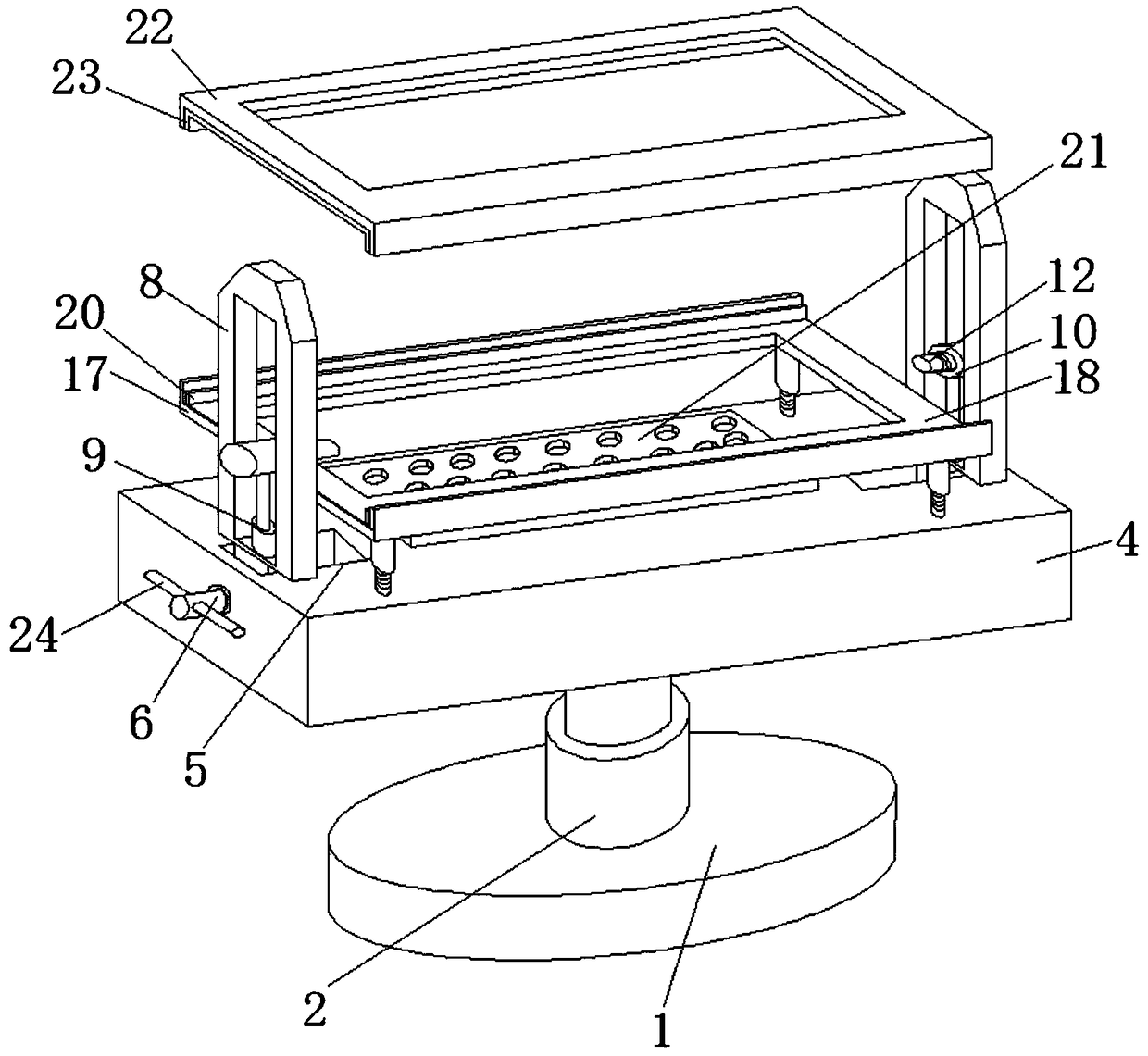

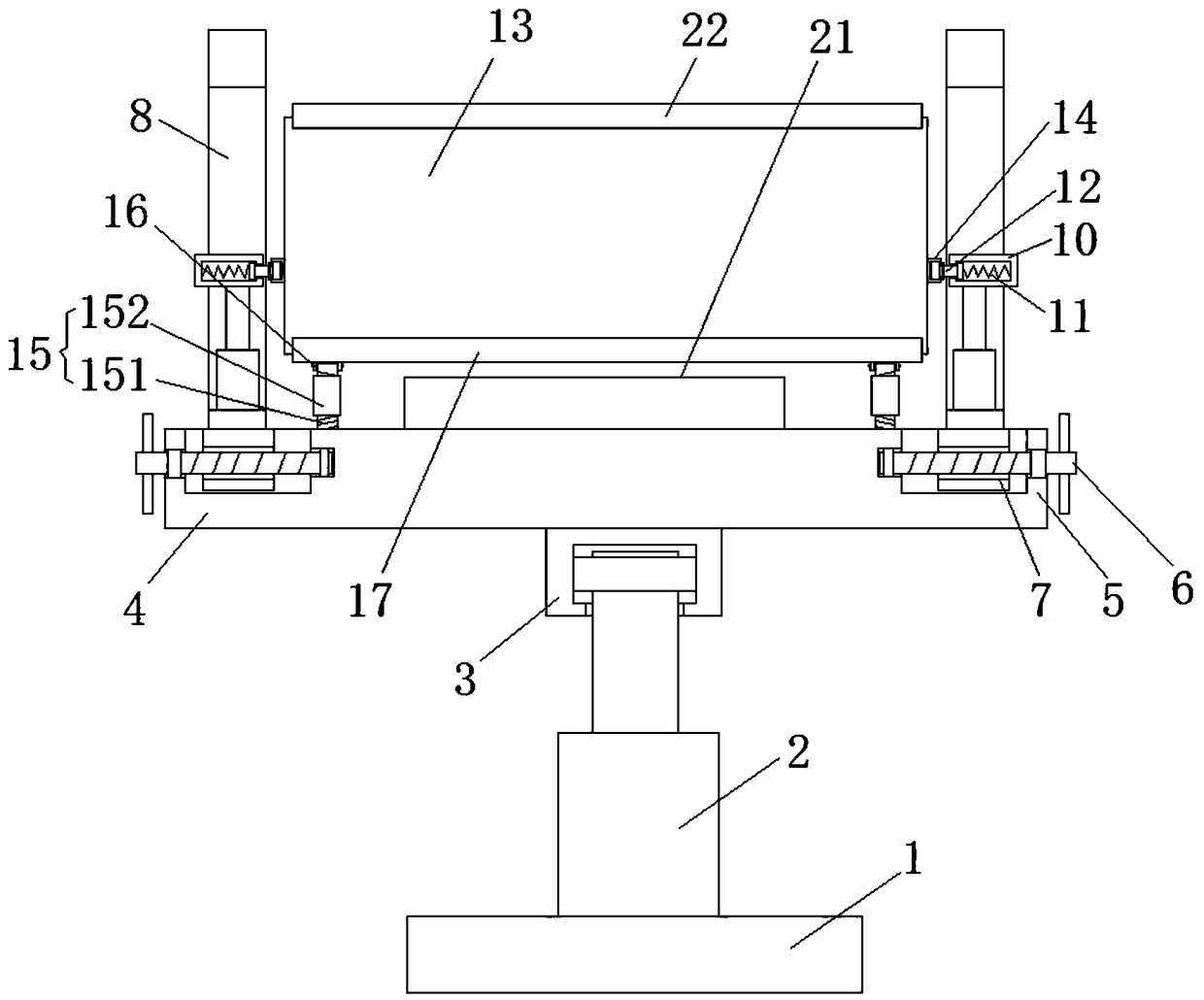

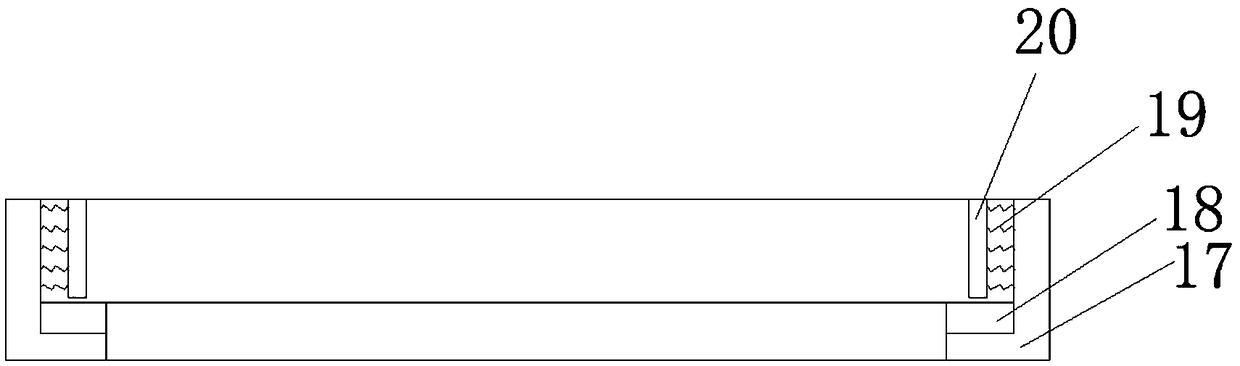

[0023] see Figure 1-4 , this embodiment provides a oscilloscope fixing device with a protective function, including a base plate 1 and an oscilloscope body 13, the top of the base plate 1 is fixedly connected with an air pressure rod 2, and the top of the air pressure rod 2 is rotatably connected with a rotating seat 3 , the top of the rotating base 3 is fixedly installed with a support plate 4, the top of the support plate 4 is provided with a mounting groove 5, the inner wall of the mounting groove 5 is rotatably connected with a screw rod 6, and the surface of the screw rod 6 is threadedly connected with a sliding block 7, the sliding block The top of 7 is fixedly connected with frame 8, and the bottom of the inner wall of frame 8 is fixedly connected with electric push rod 9, and the top of electric push rod 9 is fixedly connected with installation sleeve 10, and the inner wall of installation sleeve 10 is provided with positioning spring 11, and positioning spring One si...

Embodiment 2

[0026] see Figure 1-4 , on the basis of embodiment 1, a further improvement has been made: the inner wall of the rotating seat 3 is provided with a bearing, and the air pressure rod 2 is socketed with the bearing. Through the rotation of the bearing, the support plate 4 can be supported under the condition that the position of the air pressure rod 2 remains unchanged. The position of the wave recorder body 13 is changed, so as to change the position of the wave recorder body 13. One side of the screw rod 6 is fixedly provided with a handle 24. When the wave recorder body 13 is disassembled and installed, the screw rod 6 and the installation groove 5 joints are provided with bearings, the screw mandrel 6 is socketed with the inner ring of the bearing, the position of the frame 8 can be changed more conveniently through the handle 24, and the bearings at this place can make the rotation of the screw mandrel 6 smoother. It facilitates disassembly and installation operations.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com