Novel oil drum heating device

A technology for heating devices and oil drums, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as high safety and environmental risks, low heat transfer efficiency, high cost, etc., reaching the scope of application Broad, broad market prospects, the effect of preventing downward displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

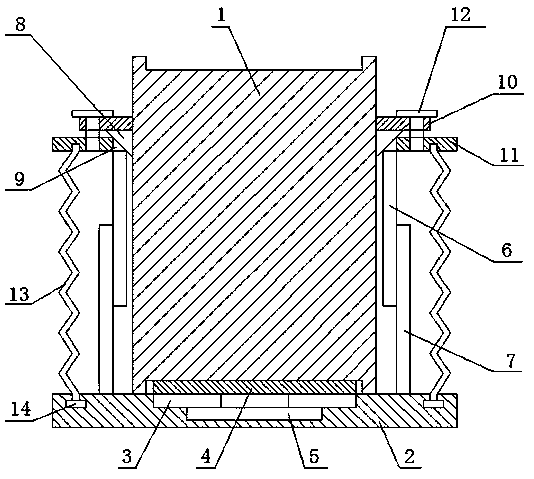

[0015] As shown in the figure, a new type of oil drum heating device is used to heat the oil drum 1, including a first heating assembly, a second heating assembly and a heat preservation assembly; the first heating assembly includes a base 2, and the base 2 has a disc-shaped structure. The middle part of the top surface is provided with a circular groove 3, and the circular groove 3 is provided with a heating disc 4 matching it, and the middle part of the groove bottom of the circular groove 3 is provided with an installation groove downwards, and the installation groove is provided with a The lifting cylinder 5, the piston rod of the lifting cylinder 5 is set upwards,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap