Fatigue damage analysis method considering loading lower than fatigue limit

A technology of fatigue limit and fatigue damage, which is applied in the direction of analyzing materials, instruments, electrical digital data processing, etc., and can solve problems such as insufficient accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

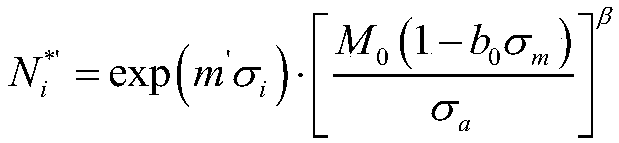

Method used

Image

Examples

Embodiment Construction

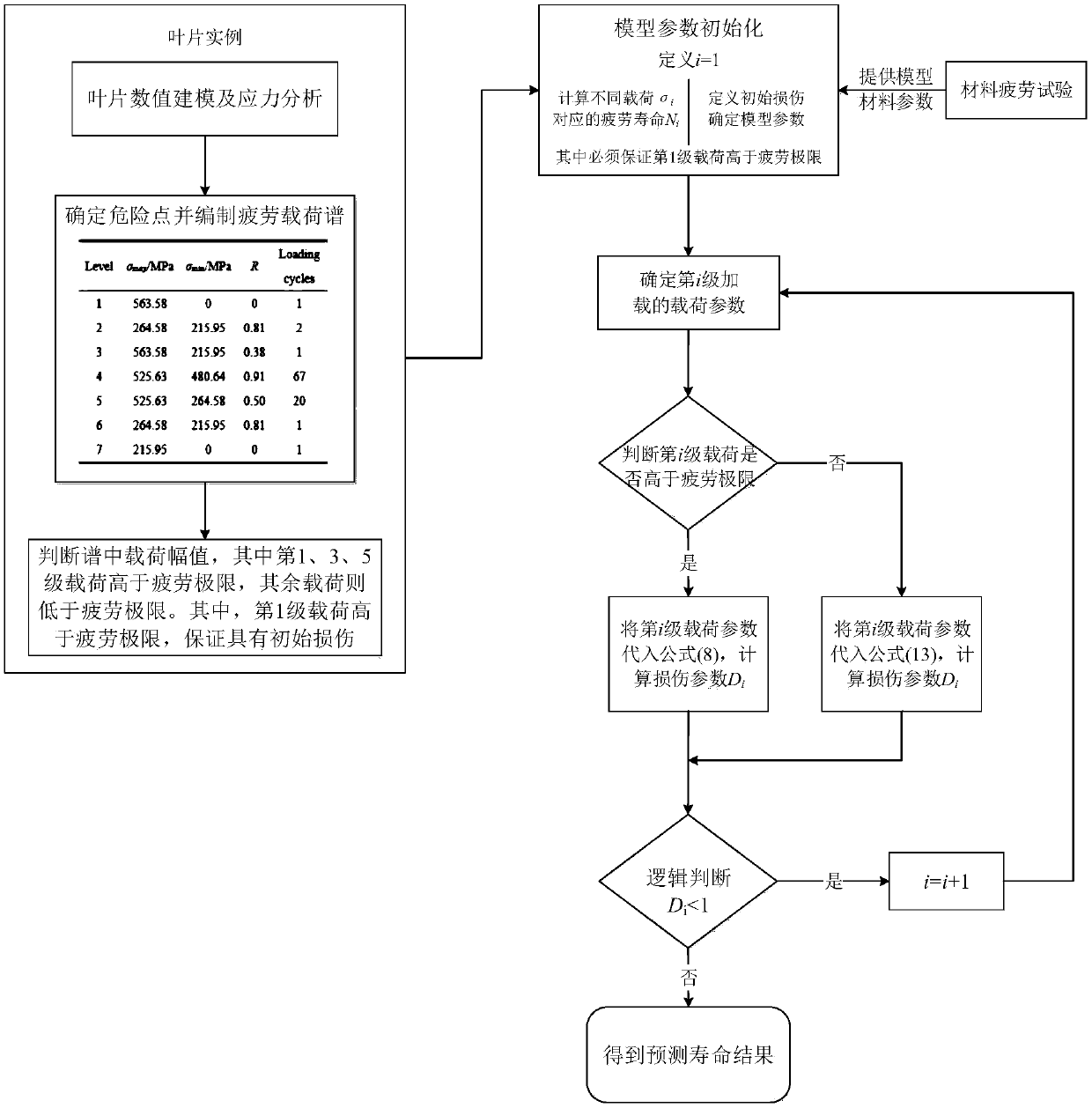

[0057] The flow of a fatigue damage prediction method considering loading below the fatigue limit is as follows: figure 1 is shown, and the iterative calculation process of the invention for the multi-level loading example is given. to combine figure 1 The characteristics and advantages of the present invention will also become clearer by describing the calculation process of the example in detail.

[0058] Apply the present invention to the life prediction of multi-stage loading, taking the compressor blade as an example, its calculation process is as follows: 1. Determine that the blade material is titanium alloy, establish the blade numerical calculation model to solve the stress distribution of the blade, and determine the proneness to occur according to the stress analysis Dangerous points of fatigue failure and compile the fatigue load spectrum; 2. Analyze the load parameters in the load spectrum, determine the load amplitude, and ensure that the first level load is hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com