=Method for calculating elastic modulus of needled C/C composite material

A composite material and elastic modulus technology, which is applied in the field of composite material and mechanical performance testing, can solve problems such as the inability to accurately and efficiently calculate the elastic properties of composite material parts, which is not conducive to the engineering application of acupuncture C/C composite materials, error fluctuations, etc. , to achieve the effect of avoiding low versatility, avoiding large errors in calculation results, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

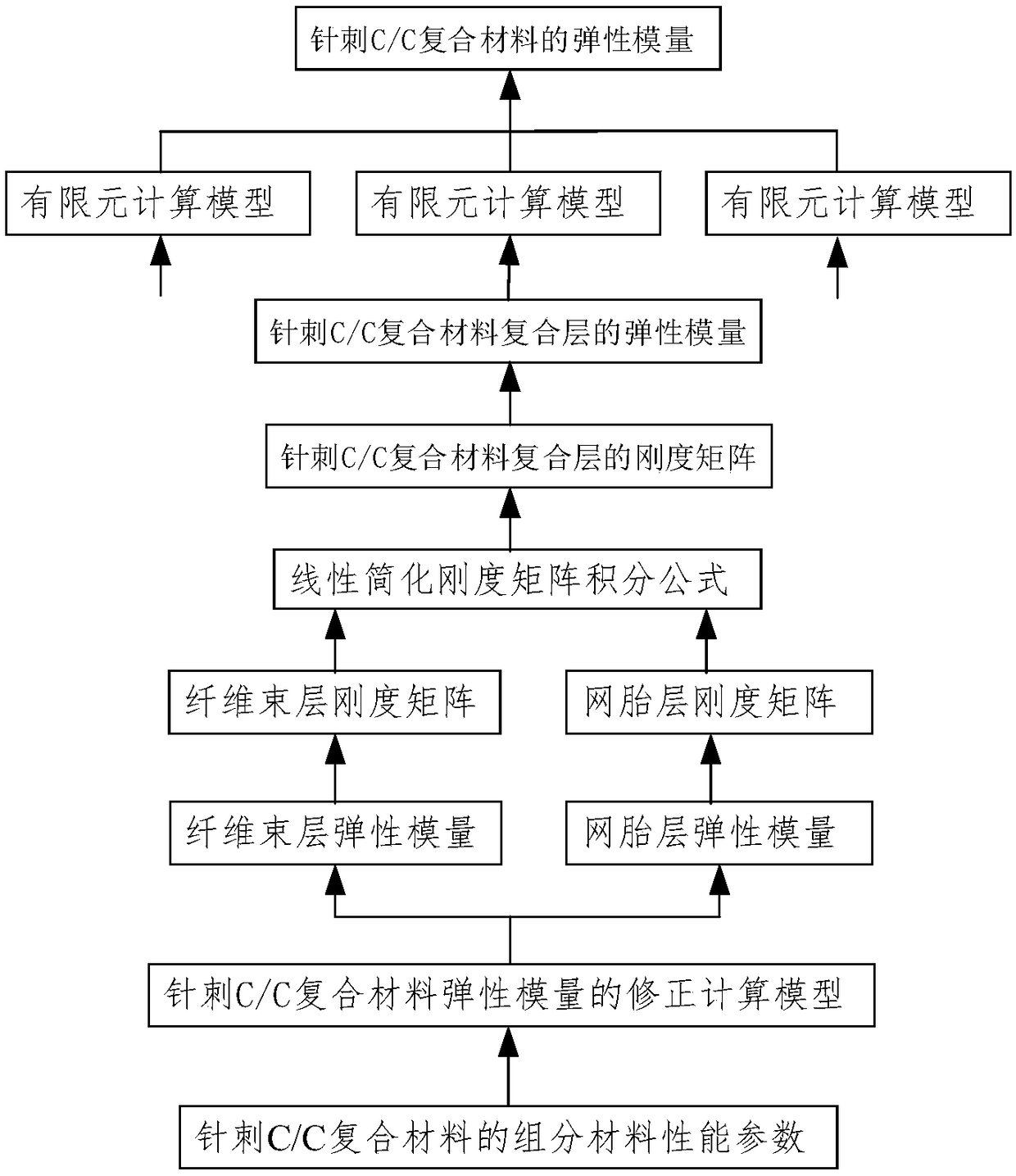

[0022] The present invention proposes a method for calculating the elastic modulus of acupuncture C / C composite materials. The calculation method is based on the calculation method of the mixing ratio of acupuncture C / C composite materials, and uses the Halpin-Tsai calculation model and the Gox equation to establish the acupuncture C / C composite material. The elastic modulus correction calculation model of C composite materials is used to study the elastic properties of acupuncture C / C composite materials, which solves the problems of large errors and low versatility caused by the calculation of elastic properties by using existing calculation methods, and realizes the accuracy of acupuncture C / C composite materials. / C Composite Elastic Modulus Accurate Calculation.

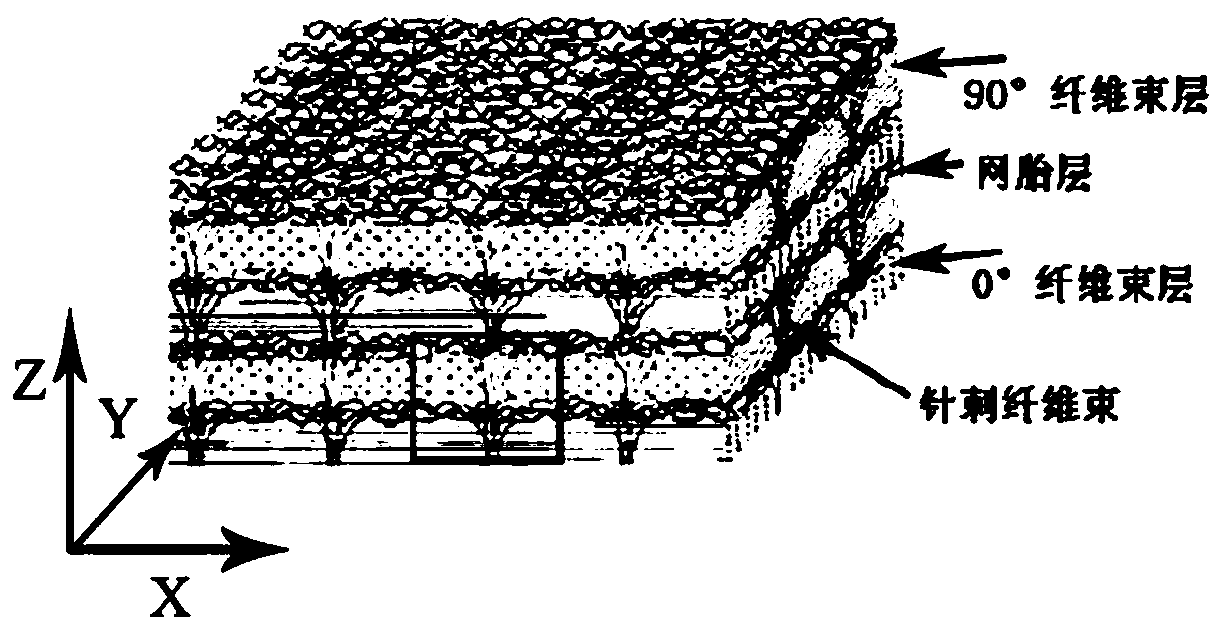

[0023] like figure 1 As shown, needle-punched C / C composites are different from or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com